Comment produire des flocons de PET de meilleure qualité avec une ligne de lavage en PET ?

Une ligne de lavage PET est un système essentiel dans le processus de recyclage du plastique, spécialement conçu pour nettoyer et…

Une ligne de lavage PET est un système essentiel dans le processus de recyclage du plastique, spécialement conçu pour nettoyer et transformer les bouteilles PET en flocons de PET de haute qualité.

La clé pour produire des flocons de PET de haute qualité

Pour produire des résines pour bouteilles PET de haute qualité, vous devez partir des aspects suivants :

Utilisation de matières premières de haute qualité

Choisir comme matière première des bouteilles PET propres et bien triées est la base. Essayez d'éviter de mélanger d'autres impuretés telles que le PVC et le métal, qui affecteraient la pureté des flocons de bouteilles PET.

Supprimer les impuretés

Configurez un équipement de séparation efficace. Tels que le dissolvant d'étiquettes de bouteilles en plastique et la séparation en plastique d'évier flottant, qui peuvent séparer efficacement les étiquettes en PVC et les bouchons de bouteilles en PP.

Optimiser le processus de lavage

L'utilisation de machines à laver avancées et de processus rationnels, tels que des cuves de lavage à chaud et des rondelles à friction, élimine efficacement les résidus d'huile, d'adhésif et d'étiquettes.

Lors du lavage à chaud, la température et la durée du lavage doivent être strictement contrôlées pour éviter d'endommager la viscosité caractéristique des flocons de bouteilles. De plus, des détergents peuvent être ajoutés en quantités appropriées pour éliminer efficacement les taches et les décolorations tenaces, mais il faut en même temps veiller à maintenir la valeur du pH dans une plage raisonnable.

Utilisation d'équipements de séchage de haute qualité

Après le nettoyage, la teneur en eau des flocons de bouteilles est assurée à moins de 0,5 pour cent grâce à une machine de déshydratation centrifuge à haut rendement et une installation de séchage à air chaud, évitant ainsi les problèmes lors du traitement ultérieur.

Qu’est-ce que les flocons de bouteilles PET de haute qualité ?

Les flocons de bouteilles PET de haute qualité présentent généralement les caractéristiques suivantes :

- Haute pureté: Contient très peu d'impuretés, notamment du PVC, du PP et du PE avec moins de 0,01%.

- Bonne transparence des couleurs: la couleur des flocons de bouteilles est proche de celle du PET vierge, sans signe évident de jaunissement ou de contamination.

- Faible teneur en eau: maintenu en dessous de 0,5% pour assurer la stabilité du processus ultérieur de granulation ou de moulage par injection.

- Uniformité de la taille des particules: contribue à un chauffage et une manipulation uniformes pour un traitement ultérieur.

Combien coûte l’installation d’une ligne de lavage PET ?

Le prix d'une ligne de lavage PET dépend principalement de la capacité, de la configuration de l'équipement et du degré d'automatisation. En règle générale, les petites lignes de recyclage coûtent environ des dizaines de milliers de dollars, et les grandes lignes de nettoyage de bouteilles en plastique peuvent coûter des centaines de milliers de dollars.

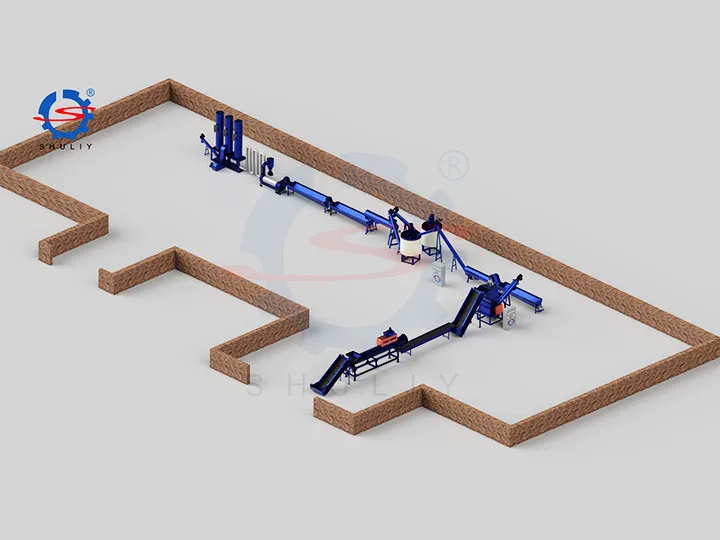

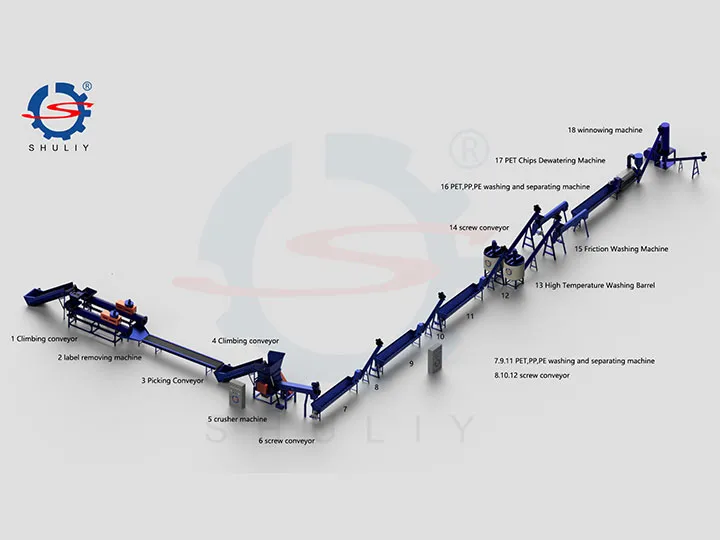

Quel équipement est inclus dans une ligne de lavage PET complète ?

- Tapis roulant: introduction de bouteilles PET dans la ligne de lavage.

- Machine à enlever les étiquettes des bouteilles PET: retirez l'étiquette sur le flacon.

- Machine de broyeur de bouteilles PET: broie les bouteilles PET en petits flocons pour un nettoyage ultérieur.

- Séparateur d'évier à flotteur: élimine les impuretés légères telles que les bouchons et les étiquettes.

- Machine à flocons PET lavés à chaud: enlève les adhésifs et les huiles avec de l'eau chaude et du détergent.

- Machine à laver à friction: La friction élimine les taches résiduelles et les produits de nettoyage.

- Machine de séchage de flocons PET: Élimine la majeure partie de l'eau de la surface des flocons.

- Machine de séparation d'air: séchage ultérieur et élimination des contaminants fins et des étiquettes.

Le rôle des flocons de bouteilles PET de haute qualité

La production de flocons de bouteilles PET de haute qualité améliore non seulement la compétitivité du marché, mais répond également à un large éventail de besoins industriels. Les principales utilisations comprennent :

Production de granulés PET recyclés : Utilisés dans la production de produits à forte valeur ajoutée tels que le soufflage de bouteilles et le moulage par injection.

Industrie textile : Les flocons de bouteilles PET peuvent être transformés en fibres de polyester pour la fabrication de vêtements, de tapis, etc.

Industrie de l'emballage : Les résines de bouteilles PET recyclées peuvent être utilisées dans la production de matériaux d'emballage de qualité alimentaire, réduisant l'utilisation de plastiques vierges.

Applications industrielles : Utilisées dans le domaine industriel pour la production de feuilles en plastique, de tuyaux et d'autres produits.

La production de flocons de bouteilles PET de haute qualité via une ligne de lavage PET peut non seulement créer des avantages économiques pour les entreprises, mais également contribuer au développement de la protection de l'environnement.

De la sélection des matières premières à la configuration des équipements, du processus de nettoyage au processus de séchage, chaque étape est cruciale pour la qualité des flocons de bouteilles. Si vous avez d'autres besoins ou questions concernant la ligne de recyclage de bouteilles en plastique, n'hésitez pas à nous contacter, nous vous fournirons des solutions professionnelles !