Plastik Atığınız İçin Doğru Geri Dönüşüm Makinasını Nasıl Seçersiniz?

Farklı plastik atık türleri, farklı geri dönüşüm makineleri gerektirir. Doğru plastik atık makinesini seçmek şunları gerektirir:

Farklı plastik atık türleri, farklı geri dönüşüm makineleri gerektirir. Doğru plastik atık makinesini seçerken atığın malzemesi, şekli, boyutu ve durumu gibi çeşitli faktörlerin dikkate alınması gerekir. Bu makale, plastik atıkların özelliklerini analiz ederek en uygun geri dönüşüm ekipmanının nasıl seçileceğini size tanıtacaktır.

Plastik Atıkların Tanımlanması Önemlidir

Doğru geri dönüşüm makinesini seçmeden önce öncelikle plastik atıklarınızı tam olarak anlamanız önemlidir. En iyi ekipmanı seçebilmeniz için atık türünü doğru bir şekilde tanımlamanıza yardımcı olacak birkaç önemli noktayı burada bulabilirsiniz.

1, Atık Plastik Malzeme Polimer Tipiniz Nedir?

Bir plastik türü geri dönüşüm için nasıl işlendiğini belirler. Örneğin, HDPE, LDPE, LLDPE, PP ve ABS gibi plastikler farklı erime akış indekslerine (MFI) ve viskozitelerine sahiptir. Bu özellikler, doğrudan pelletizasyon sistemi konfigurasyonunu etkiler:

- Kalıp kafası tipi: Hidrolik kalıp kafası yüksek viskoziteli malzemeler için uygundur, dişli kalıp kafası ise eşit şekilde erimiş plastikler için daha uygundur.

- Peletleme yöntemi: Şerit peletleme sert plastikler için uygundur ve su halkalı peletleme esnek malzemeler için uygundur.

2, Plastik Atığınızın Şekli ve Boyutu Nedir?

Atık malzemenin şekli ve boyutu, beslenme ve işlenme şeklini doğrudan etkiler. Örnek:

- Pul veya geri dönüştürülmüş malzeme: genellikle işlenmek üzere doğrudan ekstrudere beslenebilir.

- Film ruloları ve film torbaları: Tıkanmayı önlemek için özel besleme sistemleri gereklidir.

- Sert plastiklerin ön parçalanması, örn. HDPE şişeler: Ön işleme tabi tutulması için parçalama makinesi gerekebilir.

3, Plastik Atıkların Kökenleri ve Koşulları Nelerdir?

Atık malzemenin kaynağı (endüstriyel veya tüketici sonrası atık) ve temizlik derecesi de geri dönüşüm makinesi seçimini etkileyecektir:

- Sanayi sonrası atık: Genellikle daha temizdir ve doğrudan peletlemeye gidebilir.

- Tüketici sonrası kirli fakat yıkanmış ve kurutulmuş atık: Doğrudan granüle edilebilir.

- Yıkanmamış atık: Daha fazla işlenebilmesini sağlamak için eksiksiz bir yıkama ve kurutma sistemi gereklidir.

4, Üretim İhtiyaçlarınızı Göz önünde bulundurun

Plastik geri dönüşüm makinesi seçiminin de beklenen üretim kapasitenize göre belirlenmesi gerekir. Örneğin, küçük ve orta ölçekli bir geri dönüşüm tesisi, 100-500 kg/saat arasında işlem yapmak için ekipmana ihtiyaç duyabilirken, büyük ölçekli bir üretim hattı, 1.000 kg/saat veya daha fazlası için ekipman gerektirecektir.

5, Plastik Atıkların Fotoğraflarını Sağlayın

Geri dönüşüm makinasının plastik atıklarınıza uygun olmasını sağlamak için plastik atıklarınızın detaylı fotoğraflarını vermeniz tavsiye edilir. Örnek fotoğraflar sayesinde ekipman üreticileri uygun ekipman ve süreçleri daha doğru şekilde önerebilir.

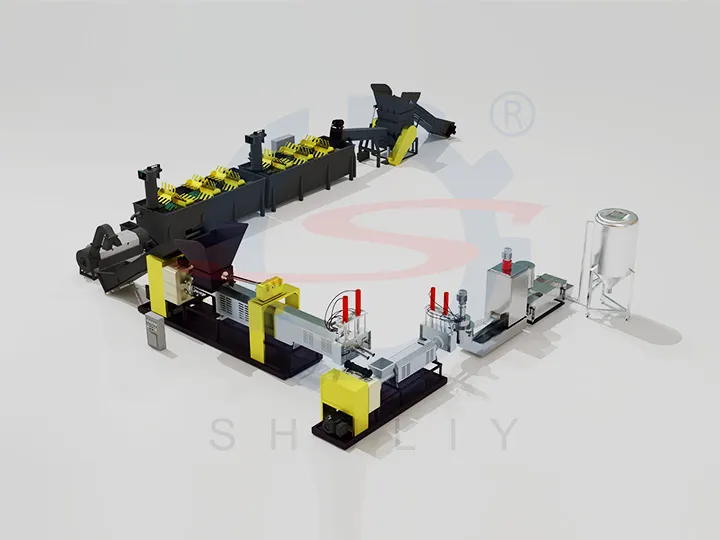

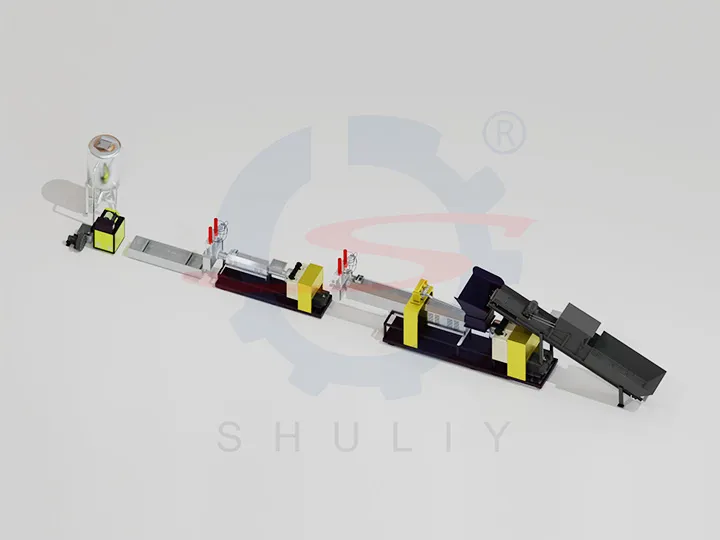

Yaygın Geri Dönüşüm Makinesi Türleri

Plastik atıkların türüne ve geri dönüşüm ihtiyaçlarına bağlı olarak aşağıdaki ekipmanlar seçilebilir:

- Kırma makinesi: Büyük plastik veya sert malzeme parçalarını daha sonraki işlemler için küçük parçacıklara veya parçalara ayırır.

- Temizleme ekipmanları: Atık malzemenin yüzeyindeki kir ve yağın uzaklaştırılmasında kullanılır.

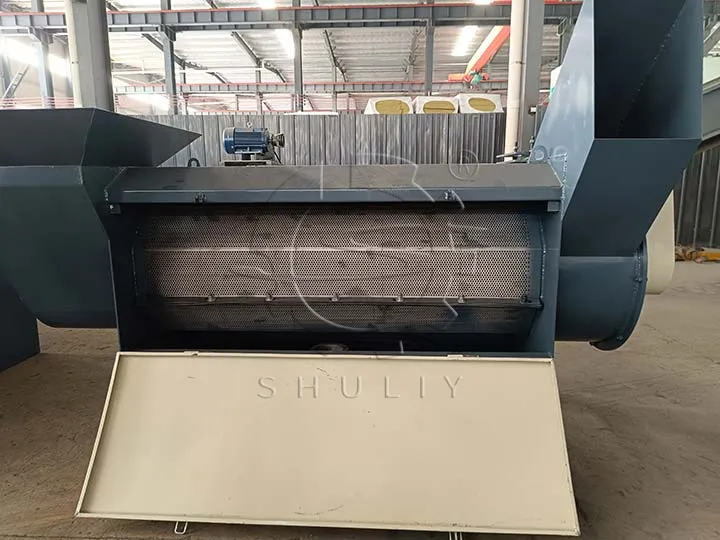

- Kurutma makinesi: Santrifüjlü susuzlaştırma makineleri ve kurutma kanalları gibi malzemenin nem içeriğini azaltmak, temiz ve kuru olmasını sağlamak için kullanılır.

- Granülasyon makinesi: Enjeksiyon veya şişirme kalıplı ürünlerin yeniden üretimi için işlenmiş plastiklerin pelet halinde işlenmesine uygundur.