EPE发泡造粒机

EPE发泡造粒机用于将EPE废旧发泡材料加工成颗粒。本文介绍了该机的工作原理、结构、规格。

EPE发泡造粒机是将EPE(可发性聚乙烯)边角料转化为颗粒的机器。EPE是一种常见的泡沫材料,常用于包装和填充材料。该机器通过加热和压缩将 EPE 废料转化为小颗粒以供重复使用。这些颗粒可用于制造新的 EPE 产品或作为其他制造工艺的原材料。

EPE珍珠棉造粒机特点

- 高效破碎造粒:EPE废料可高效破碎、熔融造粒。

- 多功能一体化设计:破碎、加热、挤压、切割于一体。

- 操作简单:人性化设计,易于使用和维护。

- 节能环保:优化能源消耗,减少废物排放。

- 可定制:设备规格和配置可根据客户需求进行调整。

EPE发泡颗粒机原材料

EPE泡沫(可发性聚乙烯泡沫)是一种常见的轻质柔性泡沫,由于其良好的缓冲性能和易于加工而被广泛应用于各个领域。 EPE造粒机可用于将珍珠棉、泡沫垫片、填充物、包装材料、瑜伽垫、泡沫儿童玩具等加工成泡沫颗粒。

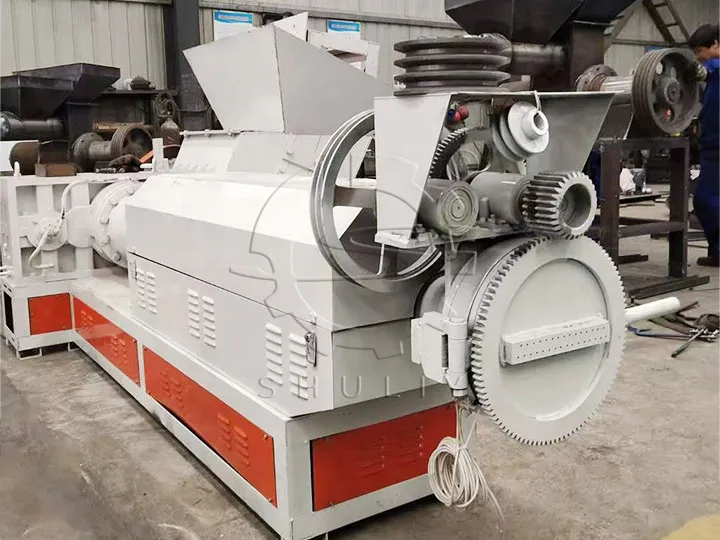

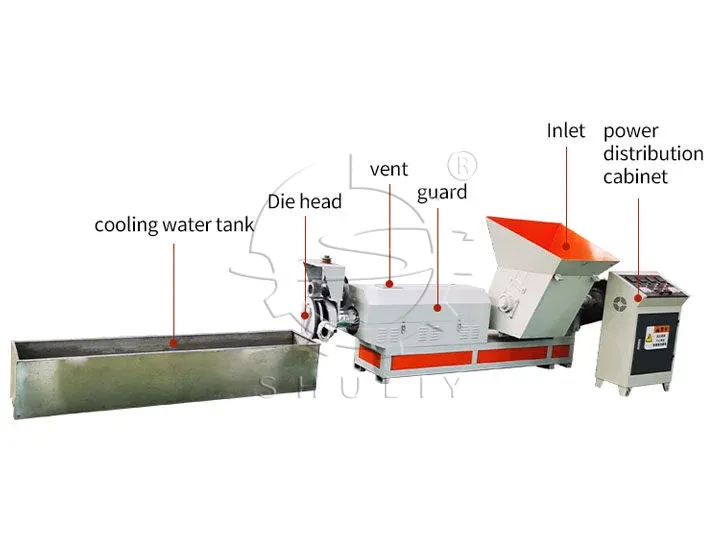

EPE发泡造粒机结构

EPE发泡颗粒机由配电柜、进风口、防护罩、排气口、模头、冷却水箱等组成。该机通过先进的加工技术,将废弃EPE材料转化为可重复使用的颗粒,为环境保护和资源利用提供解决方案。

工作准则

The foam granulator comes with its own feeding and shredding system, eliminating the need for a styrofoam shredder. The working principle of an EPE foam granulator is to crush the waste EPE foam material, then melt it by high-temperature heating, then use the extruding device to extrude the melted EPE foam into long plastic strips. Finally, it is cooled and cured into shape and enters the plastic granule cutting machine to cut into uniform plastic granules.

EPE保丽龙造粒机工作视频

EPE珍珠棉造粒机详细信息

- 制造商: Shuliy Machinery

- 型号示例:SL-160

- 产能:150-200kg/h

- 功率:30kw

- 加热方式:加热圈

- 机器尺寸:3400*2100*1600毫米

- 最终产品:EPE颗粒

- 定制:是

- 交货日期:20-25个工作日

EPE发泡造粒机出口案例

Recently, we exported an EPE granulator to Suriname to help the customer recover waste foam efficiently. Designed with recycling efficiency and energy saving in mind, the machine has a production capacity of 150-200kg/h, which can meet the customer’s needs in waste foam recycling and processing. By using this granulator, the customer can not only reduce the accumulation of foam waste but also effectively convert it into reusable granules and improve the resource utilization rate.

更多机器详情: 苏里南客户订购 EPE 和 EPS 回收用泡沫颗粒机