EPE Styrofoam Pelletizing Machine

EPE styrofoam pelletizing machine is used to process EPE waste foam material into pellets. This article describes the working principle, structure, and specifications of the machine.

The EPE styrofoam pelletizing machine is a machine for converting EPE (Expandable Polyethylene) scrap into pellets.EPE is a common foam material commonly used for packaging and filling materials. The machine converts EPE scrap into small pellets by heating and compressing it for reuse. These pellets can be used to make new EPE products or as raw materials for other manufacturing processes.

Features of EPE Granulator

- High-efficiency crushing and pelletizing: EPE waste can be efficiently crushed and melted for granulation.

- Multi-functional integrated design: crushing, heating, extruding, and cutting in one.

- Simple operation: humanized design, easy to use and maintain.

- Energy saving and environmental protection: optimize energy consumption and reduce waste emissions.

- Customizable: equipment specifications and configurations can be adjusted according to customer needs.

Raw Materials of EPE Foam Granule Machine

EPE Foam (Expandable Polyethylene Foam) is a common lightweight, flexible foam that is used in a wide variety of fields because of its good cushioning properties and ease of processing. EPE granulator can be used to process pearl cotton, foam gaskets, fillers, packaging materials, yoga mats, foam children’s toys, etc. into foam granules.

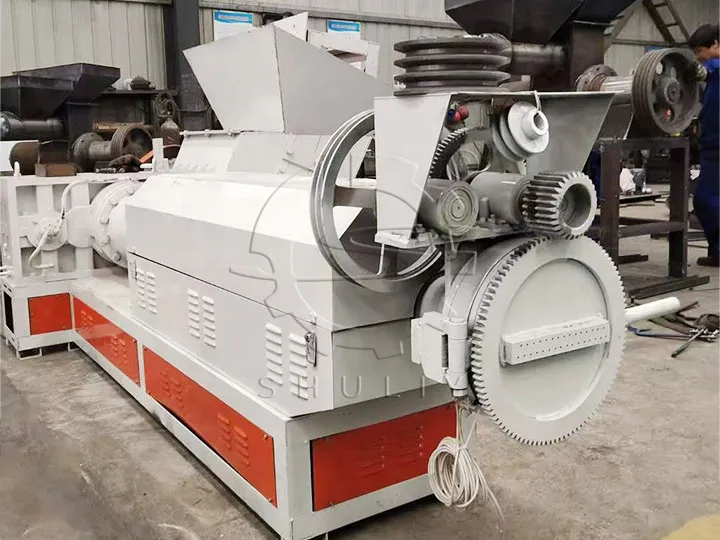

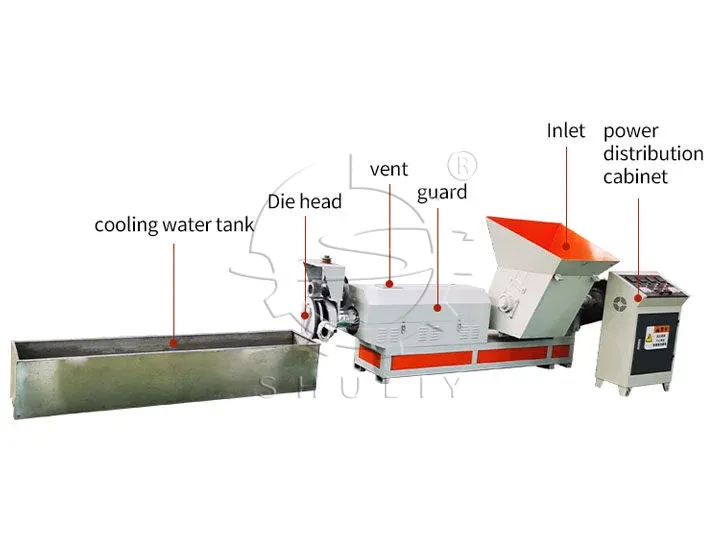

EPE Styrofoam Pelletizing Machine Structure

EPE foam granule machine consists of a power distribution cabinet, inlet, guard, vent, die head, cooling water tank, and so on. The machine provides solutions for environmental protection and resource utilization by converting waste EPE materials into reusable pellets through advanced processing technology.

Working Principle

The foam granulator comes with its own feeding and shredding system, eliminating the need for a styrofoam shredder. The working principle of an EPE foam granulator is to crush the waste EPE foam material, then melt it by high-temperature heating, then use the extruding device to extrude the melted EPE foam into long plastic strips. Finally, it is cooled and cured into shape and enters the plastic granule cutting machine to cut into uniform plastic granules.

EPE Styrofoam Pelletizing Machine Working Video

Detailed Information on EPE Granulator

- Manufacturer: Shuliy Machinery

- Example Model: SL-160

- Capacity: 150-200kg/h

- Power: 30kw

- Heating method: heating ring

- Machine size: 3400*2100*1600mm

- Final products: EPE pellets

- Customization: Yes

- Date of delivery: 20-25 working days

EPE Foam Granulator Export Case

Recently, we exported an EPE granulator to Suriname to help the customer recover waste foam efficiently. Designed with recycling efficiency and energy saving in mind, the machine has a production capacity of 150-200kg/h, which can meet the customer’s needs in waste foam recycling and processing. By using this granulator, the customer can not only reduce the accumulation of foam waste but also effectively convert it into reusable granules and improve the resource utilization rate.

More machine details: Suriname Customer Orders Foam Granulator For EPE And EPS Recycling