沉浮分离罐在PET瓶清洗回收中的关键作用

沉浮分离罐在PET瓶清洗和回收过程中起着至关重要的作用。作为…

水槽浮子分离箱在洗涤瓶洗涤和回收过程中起着至关重要的作用。作为分离杂质和提高回收效率的关键设备,它可以有效地将PP或PVC标签与PET瓶片分开,从而确保回收材料的纯度。

什么是水槽浮子箱及其功能

水槽浮子分离箱是一种使用材料密度差的设备将杂质分开,这对于宠物瓶清洁和回收尤其重要。

它使较轻的杂质(例如PP瓶盖和PVC标签)通过水的浮动和下沉特性漂浮在水面上,而较重的PET瓶片则下沉到水箱的底部,以有效分开杂质,提高瓶中的纯度,并为随后的处理提供保证。

水槽浮子分离水箱如何工作?

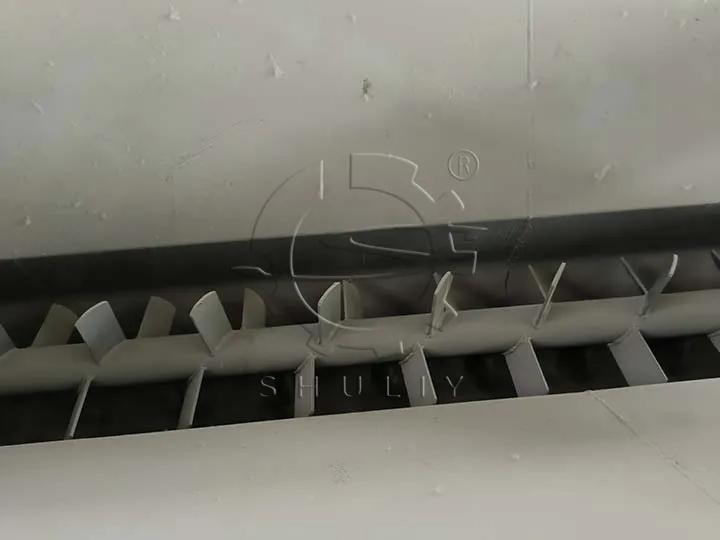

水槽浮子塑料分离根据密度差和浮力的原理起作用。当混合物进入分离箱时,低密度PP瓶盖或PVC标签浮在表面上,而高密度的PET瓶将薄片下沉到水箱的底部。

使用水流的推动和设备的设计,漂浮在地面上的杂质被排出,下沉到底部的宠物瓶片通过传送带转移到下一个过程中。

改善宠物瓶片质量

PET瓶回收过程包含大量标签,帽子和其他杂质,而没有水槽浮子分离箱,杂质将影响瓶片清洁质量和可回收材料的质量。塑料浮子水槽储罐在最初的清洁过程中清除了杂质,提供清洁剂的原材料并确保宠物瓶片的质量适合随后的加工。

我们塑料浮子水槽罐的特征

作为塑料回收设备的专业制造商,我们的水槽浮子塑料分离具有以下设计和性能的功能:

- 优化设计:机器更宽,更高,有效防止在排出杂质时将过量的瓶片被取出。

- 高效率分离:准确地将PP,PVC和其他杂质分开,以提高PET瓶片的纯度。

- 坚固耐用:采用高质量的抗腐蚀材料,适用于高湿度环境中的长期操作。

- 灵活的自定义:根据客户的需求调整大小和设计,适合不同的生产线。

- 方便的操作:简单结构,低维护成本和稳定的操作。

结论

水槽浮子分离箱在宠物瓶清洁和回收过程中起不可替代的作用。它通过有效分离杂质的同时优化生产效率来提高宠物瓶片的回收质量。我们的水槽浮子坦克为客户提供了可靠的解决方案,这要归功于其高分离效率,耐用性和灵活性。