Máquina para hacer bandejas de huevo de papel

La máquina para hacer bandejas de papel para huevos es un equipo clave que procesa pulpa de papel reciclado en…

La máquina para fabricar bandejas de papel es un equipo clave que procesa pulpa de papel reciclado en varios productos de papel moldeado. Se utiliza ampliamente para producir bandejas para huevos, bandejas para frutas y bandejas de embalaje industrial. La máquina admite múltiples capacidades de producción, que van de 1,000 a 8,000 piezas por hora, y los moldes se pueden personalizar y reemplazar fácilmente para adaptarse a diferentes formas y especificaciones de productos.

Ofrecemos soluciones completas de producción de pulpa moldeada, que incluyen selección de equipos, diseño de moldes, orientación en la instalación y soporte postventa, ayudando a los clientes a iniciar y operar de manera eficiente su producción de envases ecológicos.

Materiales crudos aplicables y gama de productos

Materias Primas

La máquina para fabricar bandejas de papel para huevos utiliza principalmente varios tipos de papel reciclado como materia prima, que son ampliamente disponibles, de bajo costo y fácilmente accesibles para los clientes localmente, lo que ayuda a reducir los costos de producción. Las materias primas comunes incluyen:

- Periódicos viejos

- Libros usados

- Cartón

- Recortes de papel

- Papel de oficina reciclado

Estos materiales se procesan a través de pulpado, tamizado y homogeneización para producir pulpa adecuada para formar.

Producto final

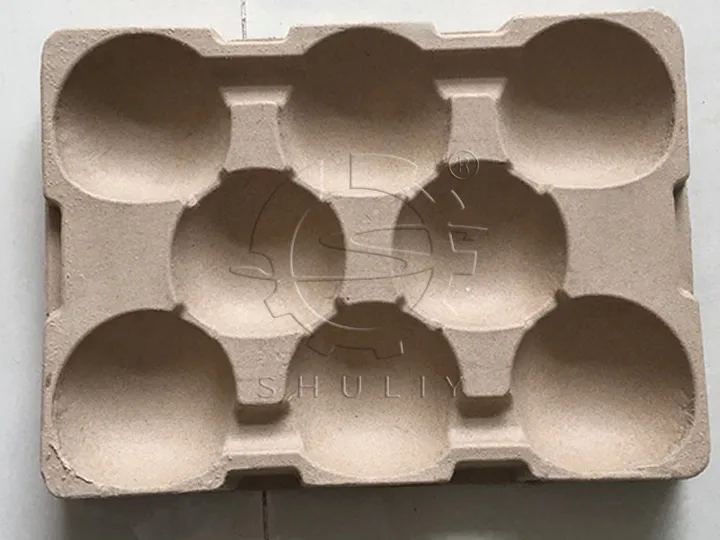

En términos de productos, la máquina para bandejas de huevos puede producir no solo bandejas de huevos estándar, sino también bandejas para huevos de pato, bandejas para huevos de ganso, bandejas para frutas, portavasos de café, soportes para zapatos y bandejas para empaquetar productos electrónicos al cambiar los moldes.

Estos productos de pulpa moldeada se utilizan ampliamente en los sectores de alimentos, agricultura y embalaje industrial, ofreciendo una excelente amortiguación, resistencia a los golpes y beneficios medioambientales. Según las necesidades del cliente, podemos personalizar moldes en diferentes formas, tamaños y grosores para satisfacer las diversas demandas del mercado.

Características de la máquina para hacer bandejas de papel para huevos

- La máquina funciona de manera estable y se puede integrar con una línea de secado para lograr una producción totalmente automática.

- Los moldes y la capacidad de producción se pueden personalizar según el tamaño del producto y los requisitos de producción del cliente.

- Soporta de 1,000 a 8,000 piezas por hora para satisfacer diferentes necesidades de producción.

- El grosor de la bandeja húmeda es de aproximadamente 2.5 mm con un contenido de humedad de hasta el 75%, requiriendo una línea de secado integrada (120–180°C) para una deshidratación eficiente.

Componentes estructurales principales de la máquina de moldes para bandejas de huevos.

La máquina para fabricar bandejas de papel principalmente consiste en moldes de formación, un sistema de succión de pulpa, un sistema de vacío, un sistema de descarga automática y un sistema de control. Los modelos con diferentes capacidades de producción varían ligeramente en el número de moldes y modos de operación. Los tipos comunes incluyen máquinas de un lado, de cuatro lados y de ocho lados, adecuadas para diferentes escalas de producción.

Principio de funcionamiento de la máquina de producción de bandejas de huevos

La máquina formadora de bandejas de huevo utiliza pulpa de papel reciclado como materia prima y forma productos de pulpa húmeda mediante succión al vacío en los moldes de formación. Las bandejas húmedas pueden secarse utilizando una línea de secado metálica, secado al aire natural o un horno de ladrillo. Después del secado, se puede utilizar una máquina de prensado en caliente para dar la forma final según sea necesario, lo que resulta en productos de pulpa moldeada con la resistencia y apariencia deseadas.

Tipos de Clientes Aplicables

La máquina para fabricar bandejas de papel es adecuada para diversos fabricantes de productos de pulpa moldeada, especialmente plantas de embalaje de huevos, fábricas de procesamiento de bandejas de papel, empresas de embalaje ecológico e inversores que buscan expandirse en negocios de embalaje verde.

Máquina para Hacer Bandejas de Huevos en Venta

Si está buscando una máquina para fabricar bandejas de huevos de papel que sea de alta eficiencia, estable y respetuosa con el medio ambiente, no dude en contactarnos para obtener más especificaciones técnicas e información sobre modelos. Le recomendaremos una solución de producción adecuada según sus necesidades específicas para ayudarle a iniciar su proyecto con éxito.