Jinsi ya Kuchagua Mashine Sahihi ya Urejelezaji kwa Taka Zako za Plastiki?

Aina tofauti za taka za plastiki zinahitaji mashine tofauti za kuchakata tena. Kuchagua mashine sahihi ya taka ya plastiki inahitaji kuchukua…

Aina tofauti za taka za plastiki zinahitaji mashine tofauti za kuchakata tena. Kuchagua mashine sahihi ya taka ya plastiki inahitaji kuzingatia mambo kadhaa kama vile nyenzo, umbo, ukubwa na hali ya taka. Makala hii itakujulisha jinsi ya kuchagua vifaa vya kuchakata vyema zaidi kwa kuchambua sifa za taka za plastiki.

Kutambua Taka za Plastiki Ni Muhimu

Kabla ya kuchagua mashine sahihi ya kuchakata, ni muhimu kwanza kuelewa kikamilifu taka yako ya plastiki. Hapa kuna mambo machache muhimu ambayo yatakusaidia kutambua kwa usahihi aina ya taka ili uweze kuchagua vifaa vyema zaidi.

1, Aina yako ya Polymer ya Nyenzo Takatifu ni ipi?

The type of polymer of a plastic determines how it is processed for recycling. For example, plastics such as HDPE, LDPE, LLDPE, PP, and ABS have different melt flow indices (MFI) and viscosities. These properties directly affect the configuration of the pelletizing system:

- Aina ya kichwa cha kufa: hydraulic die head inafaa kwa vifaa vya mnato wa juu, kichwa cha gia kinafaa zaidi kwa plastiki iliyoyeyuka kwa usawa.

- Mbinu ya pelletizing: Strand pelletizing inafaa kwa plastiki rigid, na pelletizing maji pelletizing yanafaa kwa ajili ya vifaa rahisi.

2, Je, Umbo na Ukubwa wa Taka zako za Plastiki ni zipi?

Sura na ukubwa wa nyenzo za taka huathiri moja kwa moja njia ya kulishwa na kushughulikiwa. Mfano:

- Flakes au nyenzo zilizosindika: kawaida inaweza kulishwa moja kwa moja kwenye extruder kwa ajili ya usindikaji.

- Rolls ya filamu, na mifuko ya filamu: mifumo maalum ya kulisha inahitajika ili kuzuia kuziba.

- Kabla ya kupasua kwa plastiki ngumu, k.m. chupa za HDPE: Mashine ya kupasua inaweza kuhitajika ili kuzichakata mapema.

3, Chimbuko na Masharti ya Taka za Plastiki ni nini?

Chanzo cha taka (taka za viwandani au za baada ya watumiaji) na kiwango cha usafi pia vitaathiri uchaguzi wa mashine ya kuchakata tena:

- Taka za baada ya viwanda: kwa kawaida ni safi na inaweza kwenda moja kwa moja kwenye uchujaji.

- Taka baada ya mlaji chafu lakini iliyooshwa na kukaushwa: Inaweza kuchujwa moja kwa moja.

- Taka zisizooshwa: Mfumo kamili wa kuosha na kukausha unahitajika ili kuhakikisha kuwa inaweza kusindika zaidi.

4, Zingatia Mahitaji Yako ya Uzalishaji

Chaguo la mashine ya kuchakata plastiki pia inahitaji kuamuliwa na uwezo wako wa uzalishaji unaotarajiwa. Kwa mfano, mtambo mdogo hadi wa kati wa kuchakata unaweza kuhitaji vifaa vya kuchakata kati ya 100-500kg/saa, wakati njia kubwa ya uzalishaji itahitaji vifaa kwa 1,000kg/saa au zaidi.

5, Toa Picha za Taka za Plastiki

Ili kuhakikisha kuwa mashine ya kuchakata inalingana vizuri na taka zako za plastiki, inashauriwa utoe picha za kina za taka zako za plastiki. Kwa picha za sampuli, watengenezaji wa vifaa wanaweza kupendekeza kwa usahihi zaidi vifaa na taratibu zinazofaa.

Aina za Kawaida za Mashine ya Usafishaji

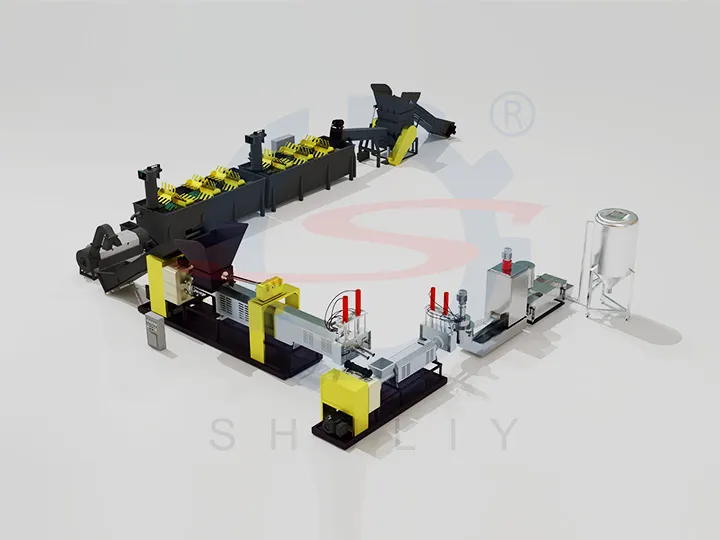

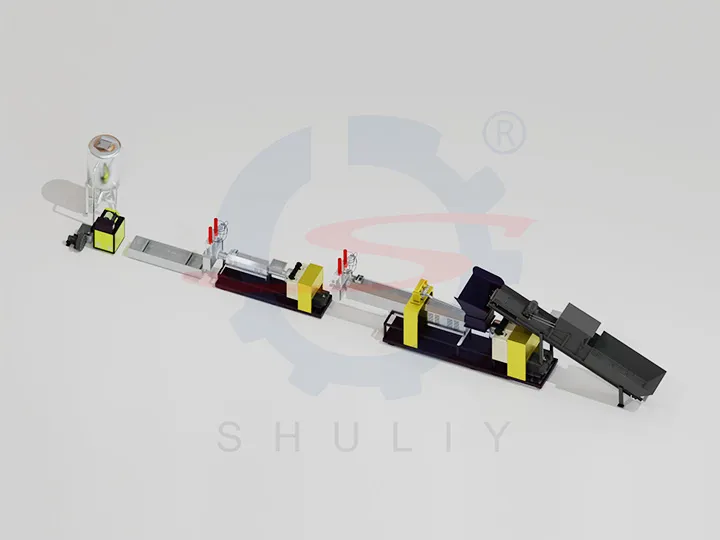

Kulingana na aina ya taka za plastiki na mahitaji ya kuchakata tena, vifaa vifuatavyo vinaweza kuchaguliwa:

- Mashine ya kusagwa: huponda vipande vikubwa vya plastiki au nyenzo ngumu kuwa chembe ndogo au vipande kwa usindikaji unaofuata.

- Vifaa vya kusafisha: kutumika kuondoa uchafu na grisi kutoka kwenye uso wa taka.

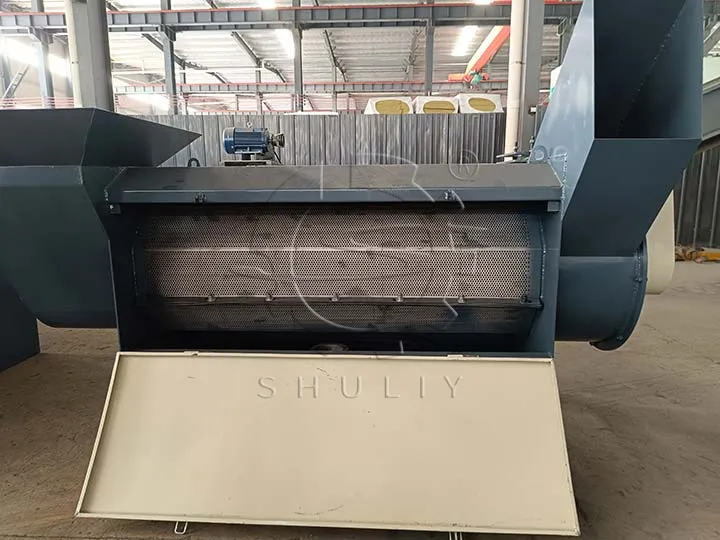

- Mashine ya kukausha: kama vile mashine ya katikati ya kuondoa maji na mifereji ya kukaushia, inayotumika kupunguza unyevu wa nyenzo na kuhakikisha kuwa ni safi na kavu.

- Mashine ya granulation: yanafaa kwa ajili ya usindikaji wa plastiki zilizotibiwa kwenye pellets kwa ajili ya uzalishaji upya wa sindano au bidhaa zilizopigwa.