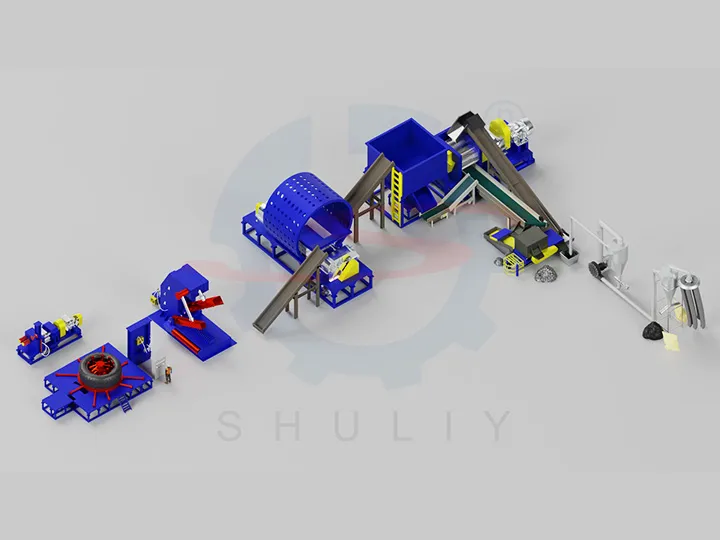

OTR Atık Lastik Geri Dönüşüm Tesisi

Büyük atık OTR lastiklerini işlemek için tasarlanmış OTR atık lastik geri dönüşüm tesisleri sunuyoruz, verimli bir şekilde işleme kapasitesine sahip…

Büyük atık OTR lastiklerini işlemek için tasarlanmış OTR atık lastik geri dönüşüm tesisleri sunuyoruz. Bu tesisler, 1.4 m'den 4 m'den daha büyük çaplara kadar lastikleri verimli bir şekilde işleyerek, müşterilerin geri dönüştürülmüş malzemelerin kalitesi ve kapasitesi konusundaki ihtiyaçlarını karşılamak için lastik granülleri veya tozu üretme kapasitesine sahiptir.

Uygulanabilir Nesneler: OTR Atık Lastik Geri Dönüşümü

OTR lastikleri (Yoldışı Lastik) madencilik kamyonları, inşaat araçları ve büyük makinelerde yaygın olarak kullanılmaktadır ve büyük boyutları, karmaşık yapıları ve yüksek çelik içeriği ile karakterizedir. Aşağıdaki lastik türleri için OTR lastik geri dönüşüm ekipmanları sunuyoruz:

- İnşaat makineleri lastikleri

- Madencilik kamyonu lastikleri (örneğin R35-R63)

- Büyük tarım veya orman lastikleri

Bitmiş Ürün: Kauçuk Tozu veya Granül

OTR atık lastik geri dönüşüm tesisinin nihai ürünü, çeşitli parçacık boyutlarına sahip kauçuk tozu veya kauçuk granülleridir; yaygın elek boyutları 5–30 mesh ve 30–60 mesh arasında değişmektedir. Elek boyutu, istenen parçacık boyutunu elde etmek için müşteri taleplerine göre ayarlanabilir.

Bu nihai ürünler, kauçuk koşu pistleri, kaldırım altlıkları, kauçuk döşeme tuğlaları, geri kazanılmış kauçuk ve kauçuk ürünlerinde dolgu maddesi olarak gibi uygulamalarda yaygın olarak kullanılmaktadır ve iyi bir katma değer sunmaktadır. Ayrıca, üretim sürecinde ayrılan çelik teller ve naylon lifler de geri dönüştürülebilir, bu da genel yatırım getirisini daha da artırır.

İki Özelleştirilmiş Geri Dönüşüm Çözümü

OTR lastik boyutları ve yapısındaki farklılıkları ele almak için, belirli çap aralıklarına göre özelleştirilmiş iki işleme çözümü sunuyoruz. Bu, ön işlemden ince kauçuk tozu üretimine kadar güvenli ve verimli geri dönüşümü sağlamaktadır.

Çözüm 1: Lastik Çapları 1400mm ile 4000mm Arasında

Bu çözüm, orta ve büyük boyutlu OTR lastiklerini hedef alır ve aşağıdaki ekipmanları içerir:

- OTR Lastik Bead Kesme Makinesi: Ekipman aşınmasını azaltmak için çelik bead tellerini çıkarır

- OTR Lastik Kesici: Lastiği yönetilebilir parçalara keser

- Lastik Parçalama Makinesi (Model 1200 ve üzeri): Lastik parçalarını kauçuk bloklara parçalar

- Ara Taşıma Bandı: Malzemeleri depolama alanına aktarır

- Otomatik Kauçuk Blok Depolama Sistemi: Malzeme beslemesini istikrarlı hale getirir

- Kauçuk Kırıcı (XKP450 modeli ve üzeri): Malzemeleri kauçuk tozuna daha da rafine eder

- Naylon Lif Separatörü: Kauçuktan naylon içeriğini çıkarır

- Kauçuk Tozu Toplama ve Taşıma Sistemi: Nihai ürünü toplar ve depolar

Çözüm 2: Ultra-Büyük Lastikler için (R35–R63)

Bu çözüm, karmaşık iç yapıya sahip ekstra büyük madencilik lastiklerinin işlenmesi için tasarlanmıştır:

- OTR Sökme Makinesi: Mühendislik lastiğini bead, diş ve üst kısım gibi 4-6 parçaya ayırarak daha fazla işleme hazırlar.

- OTR Lastik Kesici: Standartlaştırılmış parçalara keser

- OTR Çelik Tel Separatörü – Lastikten çelik halkaları ayırır

- Lastik Parçalama Makinesi (Model 1200 ve üzeri)

- Ara Conveyor Bantı

- Otomatik Kauçuk Blok Depolama Sistemi

- Kauçuk Kırıcı (XKP450 modeli ve üzeri)

- Naylon Lif Ayırıcı

- Kauçuk Tozu Toplama ve Taşıma Sistemi

OTR Atık Lastik Geri Dönüşüm Tesisinin Ana Özellikleri

OTR lastik geri dönüşüm hattımız, büyük arazi dışı (OTR) ve madencilik lastiklerini işlemek için özel olarak tasarlanmıştır, aşağıdaki ana özelliklerle:

Geniş Uygulama Alanları

1400 mm'den 4000 mm'ye kadar çaplara sahip çeşitli büyük boyutlu lastikleri, R35–R63 madencilik lastikleri, inşaat makineleri lastikleri ve büyük tarım lastiklerini işleyebilme kapasitesine sahiptir.

Yüksek Kauçuk Tozu Saflığı

Parçalama, öğütme ve hava ayırma gibi bir dizi adım aracılığıyla, nihai kauçuk tozu saflığa ulaşabilir ve geri dönüştürülmüş kauçuk ürünleri üretmek için uygundur.

Ayarlanabilir Çıkış Boyutu

Kırıcıdaki ekranları değiştirerek, kauçuk granüllerinin veya tozunun boyutu kontrol edilebilir.

Özelleştirilebilir Çözümler

Lastik boyutuna dayalı iki standart işleme şeması sunuyoruz. Ekipman konfigürasyonları, müşterinin düzenine ve üretim hedeflerine uyacak şekilde de ayarlanabilir.