タイヤ鋼線セパレーター

The tire steel wire separator is an essential machine in waste tire recycling lines. It is specially designed…

The tire steel wire separator is an essential machine in waste tire recycling lines. It is specially designed to process the bead rings cut from tires by a bead cutter, separating the embedded steel wires from the rubber. As part of a complete tire recycling machine setup, this equipment improves efficiency and ensures cleaner rubber output for further processing.

タイヤリサイクル市場の多様なニーズに応えるため、最も効率的なソリューションを提供する2種類のタイヤビードワイヤー除去機を特別に設計しました。

最初は標準モデルで、トラック、バス、一部の産業車両などの最大直径1200mmまでのタイヤを処理するために設計され、効率的かつ安定した分離を実現します。次に、大型のオフロード(OTR)タイヤ専用の重作業型OTRスチールリングセパレーターです。OTRタイヤの巨大なサイズと頑丈な構造を考慮し、このモデルは出力、構造強度、作業性能の面で全面的に強化されています。

Why is the Separation of Steel and Rubber Crucial?

In the tire recycling process, the tire bead is one of the most robust and difficult components to handle. If not separated effectively, it can lead to several problems:

- Damage to Downstream Equipment: Intact steel bead wires can cause severe wear and even damage the blades of subsequent rubber tire shredders and rubber crushers, leading to increased maintenance costs and production downtime.

- Reduced Material Value: Scrap steel contaminated with rubber fetches a lower price in the smelting market. Similarly, rubber powder or crumb rubber containing steel wire impurities is of lower quality, limiting its applications and reducing its market value.

- 処理効率の向上:鋼線を事前に分離することで、ゴムの下流の破砕や粉砕がよりスムーズかつ効率的になり、全体の処理能力が向上します タイヤ処理プラント.

Working Principle of Tire Steel Wire Separator

The machine operates with two counter-rotating rollers running at the same speed. When the tire bead ring is fed into the gap between the rollers, it is compressed, squeezed, and torn repeatedly until the steel wire is completely separated from the rubber. This mechanical process ensures effective separation and prepares the material for subsequent steps such as shredding, or rubber powder milling.

Tire Wire Removal Machine Working Video

Main Features of Tire Steel Wire Separator

- Effective Separation: Designed to handle tire bead rings and separate steel wire with high efficiency.

- Durable Structure: Robust rollers and frame ensure stable operation and long service life.

- Easy Operation: Simple feeding process with reliable separation results.

- Support for Recycling Lines: Works in combination with bead cutters, tire shredders, and rubber powder machines.

タイヤワイヤー除去機のモデルと技術仕様

トラックの標準タイヤから巨大なOTRタイヤまで、あらゆる規模の作業に対応する専用ソリューションを揃え、特定の処理要件に正確に対応できる2種類のスチールワイヤーセパレーターを提供しています。

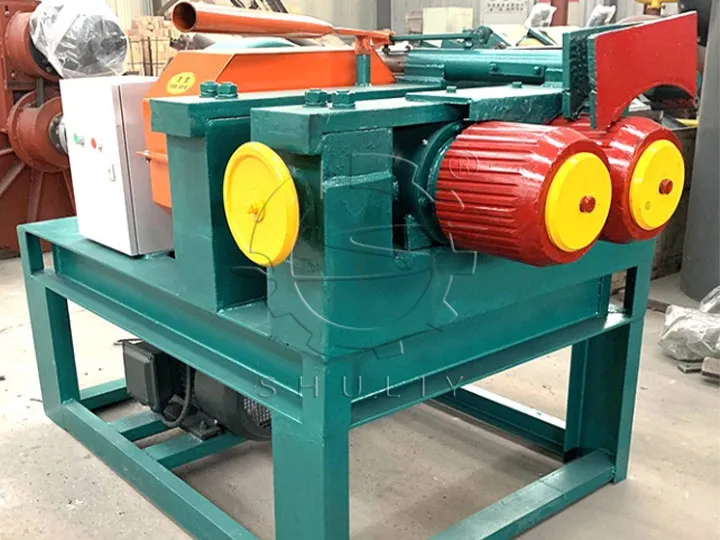

標準モデル:タイヤスチールワイヤーセパレーター

この標準モデルは、最大直径1200mmまでのトラック、バス、その他のタイヤに適した、通常サイズのタイヤを処理するための理想的な選択です。2つの逆回転ローラーを使用してタイヤリムを強力に押し出し、せん断し、引き裂き、鋼とゴムを効率的に分離します。これにより、タイヤリサイクル工場での高効率作業に欠かせない基本的な装置となります。

| 技術仕様 | 詳細 |

| 総出力 | 18.5 KW |

| 容量 | 約120リム/時 |

| 寸法(長さWH) | 2m * 1.9m * 1.8m |

| Weight | 1800 kg |

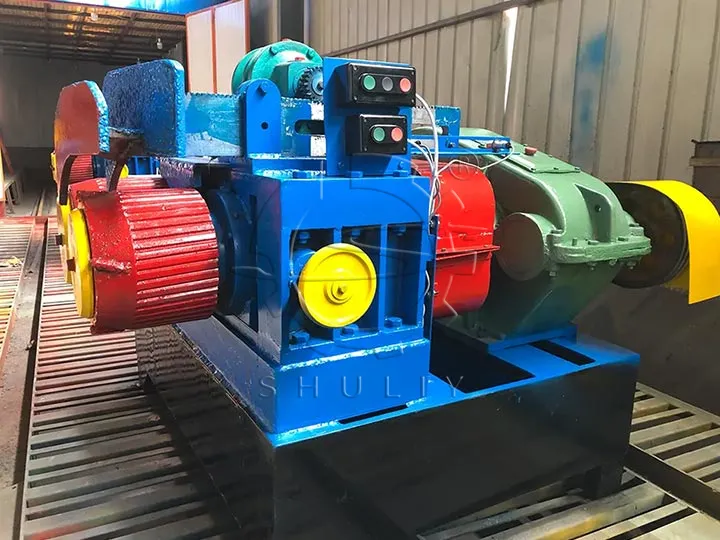

重作業型モデル:OTRタイヤワイヤー除去機

大型オフロード(OTR)タイヤ専用に設計されたこの重作業型モデルは、より頑丈な構造と強力な駆動システムを備えています。直径1400mmから4000mmまでの巨大なタイヤのリムを処理することが可能です。OTRタイヤビードに見られる硬く厚いスチールワイヤーに対しても、このタイヤスチールワイヤーセパレーターは信頼性高く完全に分離作業を行うことができ、大規模なタイヤリサイクル施設にとって欠かせない装置となっています。

| 技術仕様 | 詳細 |

| モデル番号 | OTRタイヤワイヤー除去機 |

| 総出力 | 35.5 KW |

| 容量 | 1リムあたり約2〜5分 |

| 寸法(長さWH) | 3.65m * 2.1m * 1.95m |

| 適用範囲 | 直径1400mm〜4000mmのタイヤのリム |

| Weight | 6200 kg |

Applications in Tire Recycling

The tire steel wire separator is widely used in:

- Waste tire recycling plants – to remove bead wires efficiently

- Rubber powder production lines – preparing clean rubber material for milling

- Scrap tire processing facilities – reducing wear on shredders and grinders by removing steel first

By ensuring that the steel is cleanly separated from rubber, the machine helps extend the lifespan of downstream equipment and improves the quality of recycled rubber.

Key Equipment for Enhancing Tyre Recycling Efficiency

As an important tire processing equipment, the tire steel wire separator offers an efficient solution for bead wire removal in waste tire recycling. Its reliable operation and integration with other machines such as bead cutters, tire shredders, and rubber powder mills make it a valuable part of a complete tire recycling line.

If you are planning to set up or upgrade a tire recycling plant, this machine can help improve processing efficiency and product quality.