Машина для резки текстильных отходов

Машина для резки текстильных отходов является важным оборудованием для бизнеса по переработке текстиля, швейных фабрик и…

Машина для резки текстильных отходов является важным оборудованием для бизнеса по переработке текстиля, швейных фабрик и заводов по переработке нетканых материалов. Эта машина предназначена для резки отходов ткани, старой одежды, тряпок, денима, хлопка и других мягких материалов на мелкие, удобные куски, и играет ключевую роль в сокращении отходов и повторном использовании материалов. Независимо от того, перерабатываете ли вы ткань для подкладки, изоляции или регенерированных волокон, высококачественная машина для резки может значительно повысить вашу производственную эффективность.

Мы предлагаем пять различных моделей с производительностью от 300 кг до 5000 кг в час, что делает их подходящими для широкого спектра применений, от небольших мастерских до крупных заводов. Машина позволяет регулировать размеры выходной продукции от 5 мм до 300 мм, с толщиной реза от 20 мм до 200 мм, обеспечивая гибкость для обработки различных материалов и требований.

Что такое машина для резки текстильных отходов?

Машина для резки текстильных отходов, также известная как машина для резки хлопковых отходов или текстильная резальная машина, является механическим устройством, используемым для нарезки или рубки текстильных отходов на мелкие размеры для дальнейшей переработки. Она оснащена ротационными лезвиями, системой подачи и механизмом безопасности для обеспечения постоянного резания и безопасности оператора. Эти машины подходят для обработки различных типов материалов, включая:

- Хлопковые и полиэстеровые ткани

- Деним и джинсы

- Нетканые материалы

- Старая одежда и тряпки

- Отходы пряжи и вязаных тканей

Готовая продукция и применение машины для резки волокна

Машина для резки текстильных отходов производит короткие волокна с равномерной длиной, подходящие для различных последующих процессов. Распространенные применения включают:

- Открытие: Резанные волокна могут быть непосредственно поданы в машины для открытия волокна для дальнейшего рыхления.

- Наполнитель: Идеально подходит для использования в подушках, игрушках, матрасах, диванах и других наполнителях.

- Литье под давлением: Применимо для производства теплоизоляционных плит, звукопоглощающих панелей и переработанных хлопковых изделий.

- Переработанное волокно сырьё: Используется в качестве базового материала для переработанных пряж, нетканых тканей и т.д.

Резанные волокна имеют равномерный размер, низкое содержание примесей, легко хранятся и транспортируются, что делает их важным промежуточным продуктом в переработке волокна.

Преимущества нашей текстильной резательной машины

- Широкая совместимость материалов: Подходит для переработки полиэфирного волокна, хлопкового волокна, нетканых тканей, отходов ткани, растительного волокна и др.

- Регулируемая длина резки: Множество вариантов длины резки для удовлетворения различных требований к обработке.

- Широкий диапазон мощностей: Доступно в различных моделях с производительностью от 300 кг/ч до 5000 кг/ч, подходит как для маломасштабных, так и для крупномасштабных производственных линий.

- Настраиваемая электрическая конфигурацияНапряжение и мощность двигателя могут быть адаптированы в зависимости от страны заказчика и производственных потребностей.

- Универсальное конечное использованиеРезаные волокна идеально подходят для открывания, заполнения, сжатия и могут быть использованы с машинами для открытия волокон.

- Доступна настройка и оптовые скидкиТехнические характеристики оборудования могут быть настроены, предлагая эксклюзивные скидки на оптовые закупки.

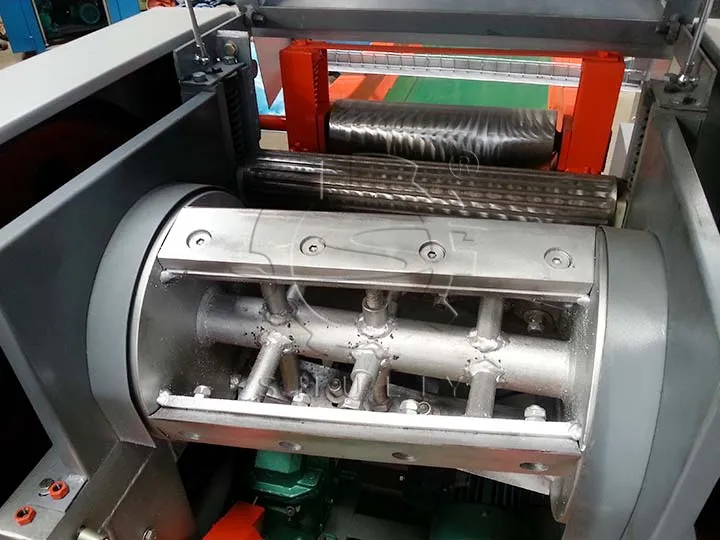

Принцип работы машины для резки текстильных отходов

Машина для резки текстильных отходов в основном использует срезающую силу между высокоскоростными вращающимися лезвиями и неподвижными лезвиями для резки длинных волокон, отходов ткани или нетканых материалов на равномерно размеренные короткие волокна. Рабочий процесс обычно включает в себя следующие этапы:

- Подача: Материалы равномерно подаются в зону резки через ленточный или роликовый конвейер, чтобы предотвратить засорение или накопление материала.

- Ротационное резание: Ротационные лезвия на основном валу работают в координации с фиксированными лезвиями ниже, чтобы эффективно резать материал. Длина реза может быть отрегулирована и определяется количеством лезвий, скоростью вращения и скоростью выгрузки.

- Выброс: Обрезанные короткие волокна выбрасываются через выход и могут быть непосредственно отправлены на следующий процесс (например, на машина для открытия волокна) или собраны для упаковки.

Параметры машины для резки текстильных отходов

| Модель | 500 | 800 | 1200 | 1600 | 2400 |

| Мощность мотора | 5.5 + 1.5 кВт | 7.5 + 1.5 кВт | 15 + 2.2 кВт | 18.5 + 3.0 кВт | 22 + 3.0 кВт |

| Емкость | 300–500 кг/ч | 500–800 кг/ч | 800–1200 кг/ч | 1000–3000 кг/ч | 2000–5000 кг/ч |

| Размер резки | 5–150 мм | 5–150 мм | 5–150 мм | 5–300 мм | 10–300 мм |

| Толщина реза | 20 мм | 30–50 мм | 30–50 мм | 30–150 мм | 30–200 мм |

Услуги, которые мы предоставляем

Мы предлагаем широкий спектр услуг по настройке оборудования, включая тип лезвия, длину реза, спецификации напряжения и ширину подачи — все адаптировано под характеристики вашего материала и условия эксплуатации.

Кроме того, мы предоставляем сопутствующее оборудование, такое как машины для открытия волокна, конвейеры и пресс-подборщики, чтобы обеспечить бесшовную интеграцию в вашу производственную линию.

Для послепродажной поддержки мы предлагаем руководство по установке, обучение по эксплуатации, техническую помощь на основе видео и долгосрочное обеспечение запасными частями, чтобы помочь вам достичь эффективного производства и стабильной работы.

Свяжитесь с нами для получения предложения по машине для резки текстильных отходов.

Если вы ищете эффективное и надежное решение для резки волокна, наши машины для резки текстильных отходов являются идеальным выбором. Независимо от того, обрабатываете ли вы полиэстер, хлопковое волокно, нетканый материал или различные виды текстильных отходов, мы можем предложить подходящие модели и индивидуальные услуги, чтобы удовлетворить ваши потребности. Не стесняйтесь обращаться к нам через наш веб-сайт, электронную почту или WhatsApp. Сообщите нам о типе вашего материала, требованиях к мощности и любых конкретных запросах — мы оперативно свяжемся с вами с подробной сметой и профессиональными рекомендациями, чтобы помочь вам эффективно начать производство.