Mashine ya Kusaga Chupa ya PET

Mashine ya kusagwa chupa ya PET ni kifaa maalumu cha kusaga taka za chupa za PET vipande vipande. Nakala hii ni utangulizi wa kina wa mashine, pamoja na kanuni yake ya kufanya kazi, muundo, vipimo, bei na kadhalika.

Mashine ya kusaga chupa ya PET ni kipande cha kifaa kilichoundwa mahsusi kuponda na kusindika chupa za PET zilizotupwa, aina ya kawaida ya chupa ya plastiki inayotumika kufunga vinywaji, chakula na bidhaa zingine za kioevu. Mashine ya kuchakata PET hukata chupa za PET zilizotupwa kuwa vipande vidogo au vishindo kupitia nguvu ya kiufundi, na kuifanya iwe rahisi kusafisha na kuchakata baadaye.

Mashine yetu ya kusaga chupa imetengenezwa kwa chuma cha hali ya juu, na vile vile vyenye ncha kali na vya kudumu na muundo thabiti, ambao unaweza kufanya kazi kwa utulivu kwa muda mrefu. Muundo wake unazingatia utendakazi rahisi na matengenezo, kuhakikisha kwamba watumiaji wanaweza kutumia na kudumisha vifaa kwa urahisi.

Vipengele vya Mashine Yetu ya Kusaga Chupa

- Nyenzo ya Blade: Imetengenezwa kwa 9CrSi ya kudumu kwa utendakazi wa kudumu.

- Mesh ya Skrini Inayoweza Kurekebishwa: Saizi ya Mesh ni 16-18mm, inaweza kubinafsishwa kwa mahitaji tofauti.

- Kubinafsisha: Inapatikana ili kukidhi mahitaji maalum ya usindikaji.

- Mifano Nyingi: Hutoa aina mbalimbali za miundo ili kushughulikia uwezo tofauti wa uzalishaji.

Malighafi na Bidhaa Zilizokamilika

Malighafi ya mashine za kusaga chupa za PET ni taka za chupa za PET ambazo zinaweza kuwa chupa tupu kutoka kwa bidhaa mbalimbali za walaji kama vile vinywaji, chakula, sabuni, n.k. Kwa kawaida chupa za PET huwa na mwonekano wa uwazi, nusu uwazi au rangi, na hukusanywa. na kupangwa kabla ya kulishwa kwenye mashine ya kuchakata PET kwa ajili ya kuchakatwa.

Bidhaa iliyokamilishwa ya mashine ya kupasua chupa ni chipsi za plastiki za PET, chipsi za plastiki za PET kawaida huwa na maumbo na saizi zisizo za kawaida, huchakatwa na crusher, na zinaweza kutumika kwa kuchakata tena, kama vile malighafi kwa utengenezaji wa chupa mpya za PET, nguo, vifaa vya ujenzi na kadhalika.

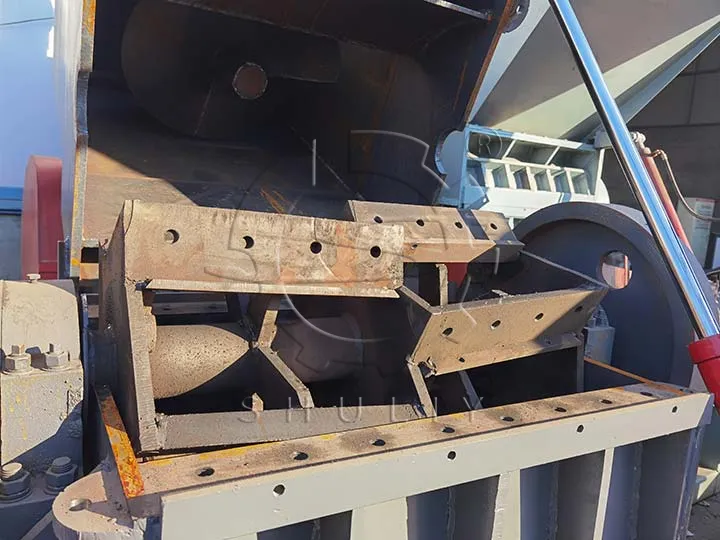

Muundo wa Mashine ya Kusaga Chupa ya PET

Mashine ya kuchambua PET kwa kawaida huwa na vipengee kuu kama vile ghuba ya mlisho, zana ya kukata, rota, skrini, kipunguza, injini, mlango wa kutokeza maji na mwili. Vipengele hivi hufanya kazi pamoja ili kuwezesha chupa za PET zilizotupwa kuchakatwa kwa kukatwa, kusagwa na kukaguliwa, na hatimaye kuzibadilisha kuwa vipande vya plastiki vya PET vinavyoweza kutumika tena.

Je! Kikandamizaji cha Chupa cha PET Inafanyaje kazi?

Mashine ya kusaga mabaki ya chupa ya PET hufanya kazi kwa kutumia nguvu ya kimitambo kukata na kuponda chupa za PET kuwa vipande vidogo au vipande vidogo. Mchakato wake wa kufanya kazi kawaida ni pamoja na hatua zifuatazo:

- Mlisho: Chupa za PET taka huwekwa ndani ya mashine ya kusaga chupa za plastiki kupitia upenyo wa malisho. Chupa hizi zinaweza kutibiwa mapema, kama vile kuondoa lebo, kofia, na uchafu mwingine, kwa ajili ya kupasua vizuri zaidi baadae.

- Kusagwa: Baada ya chupa ya PET kuingia kwenye mashine, rotor huanza kuzunguka, kuendesha visu zilizowekwa juu yake ili kufanya shughuli za kukata na kusagwa. Visu huzunguka kwa kasi ya juu na kukata chupa za PET vipande vidogo au vipande.

- Uchunguzi: Chipu za PET zilizokandamizwa hupitishwa kupitia skrini, ambayo hutumika kuhakikisha kuwa vipande vya plastiki vya PET pekee vya ukubwa unaofaa hupitia.

- Utoaji: Vibao vya chupa za PET vilivyochunguzwa hutolewa kutoka kwa mashine ya kusaga chupa ya PET kupitia kwa kituo au katika hatua inayofuata ya kuchakata tena.

PET Shredder Machine Working Video

Vipimo vya Mashine ya Kusaga Chupa ya Plastiki

Haya hapa ni maelezo ya maelezo ya miundo kadhaa moto ya mashine za kusaga chupa za PET kwa marejeleo yako. Mashine zetu zinaweza kubinafsishwa kulingana na mahitaji ya mteja, kama vile saizi ya skrini, mwonekano wa mashine, na kadhalika.

| Mfano | SL-60 | SL-80 | SL-100 |

| Uwezo (kg/h) | 500 | 1000 | 1500 |

| Motor (kW) | 22 | 37 | 75 |

| Urefu (m) | 1.8 | 2.6 | 2.6 |

| Unene wa kisu (mm) | 30 | 40 | 40 |

| Unene wa sahani (mm) | 16 | 20 | 30 |

Jinsi ya Kudumisha Mashine ya PET Shredder?

Ili kuhakikisha operesheni thabiti ya muda mrefu na kazi bora ya mashine ya kusaga chupa ya PET, matengenezo ya mara kwa mara na ukarabati inahitajika. Hapa kuna njia za kawaida za kudumisha mashine ya kusaga chupa:

- Iweke safi: Safisha mara kwa mara sehemu zote za mashine ya kusaga PET, haswa sehemu ambazo huwa na mkusanyiko wa uchafu, kama vile visu, skrini na milango ya mipasho. Kuweka mashine safi ndani na nje itasaidia kuepuka mkusanyiko wa uchafu na kudumisha uendeshaji mzuri wa vipengele.

- Ulainishaji wa kawaida: Kwa sehemu zinazohitaji kulainishwa, kama vile fani za rota, kipunguza, n.k., ongeza kiwango sahihi cha mafuta au grisi mara kwa mara ili kupunguza msuguano na uchakavu na kuongeza muda wa maisha ya huduma ya sehemu hizo.

- Angalia na kaza Bolts: Angalia mara kwa mara sehemu mbalimbali za kuunganisha na bolts za mashine ya kusaga chupa ya PET ili kuhakikisha kuwa zimeimarishwa kwa usalama ili kuepuka kulegea au kutengana ambayo inaweza kusababisha kukosekana kwa utulivu au uharibifu kwa mashine.

- Ubadilishaji wa sehemu zilizochakaa mara kwa mara: Angalia mara kwa mara visu, skrini, na sehemu nyingine ambazo ni rahisi kuvaa, na ubadilishe kwa wakati pindi tu zinapoonekana kuwa zimevaliwa au zimeharibika, ili kuhakikisha uendeshaji wa kawaida wa mashine na ufanisi wa kusagwa. .

Bei ya Mashine ya Kusaga Chupa ya Plastiki

Wakati wa kuzingatia bei ya mashine ya kusaga chupa ya plastiki, mambo mbalimbali yanahusika. Hizi zinaweza kujumuisha uwezo wa mashine, vipengele, sifa ya chapa na mahitaji ya soko. Kwa ujumla, bei inaweza kuanzia mia chache hadi dola elfu kadhaa, kulingana na mfano na vipimo.

Tunatoa anuwai kubwa ya mashine za kusaga chupa za plastiki pamoja na suluhisho kamili za kurudiwa kwa chupa za PET kwa bei ambazo zinatofautiana kulingana na vipimo na sifa za vifaa. Tumejizatiti kutoa bidhaa za ubora wa juu ili kukidhi mahitaji ya wateja wetu na kuwapa bei za ushindani. Tunajitahidi kuwapa wateja wetu suluhisho bora bila kujali ukubwa wa bajeti yao.