Sink Float Plastic Separation

Mgawanyiko wetu wa plastiki ya kuelea ni mashine iliyoundwa mahsusi kwa mimea ya kuosha chupa za PET kusafisha na kutenganisha plastiki iliyochanganywa. Kazi yake kuu ni kutenganisha kwa ufanisi flakes za chupa za PET kutoka kwa lebo au kofia zilizofanywa kwa PP, PE, nk.

Mgawanyiko wetu wa plastiki ya kuelea ni mashine iliyoundwa mahsusi kwa mimea ya kuosha chupa za PET kusafisha na kutenganisha plastiki iliyochanganywa. Kazi yake kuu ni kutenganisha kwa ufanisi flakes za chupa za PET kutoka kwa lebo za PVC au kofia za PP, ili kutoa malighafi safi kwa usindikaji unaofuata.

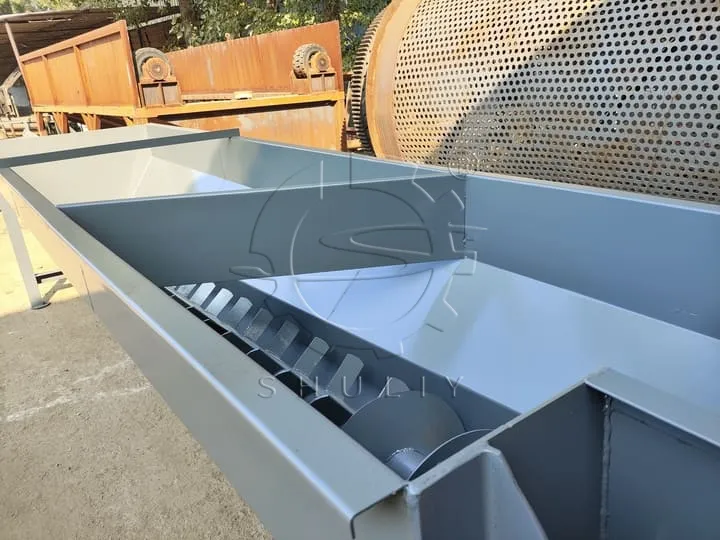

Tangi letu la kutenganisha kuelea kwa sinki limeundwa kuwa la hali ya juu na rahisi kufanya kazi, likiwa na ufanisi bora wa utenganisho na uwezo wa usindikaji. Vifaa vinafanywa kwa vifaa vya ubora na uimara wa juu ili kuhakikisha uendeshaji thabiti wa muda mrefu. Kwa kuongeza, tunatoa huduma maalum ili kurekebisha na kuboresha vifaa kulingana na mahitaji maalum ya wateja.

Vipengele vya Mashine ya Kuosha Flakes za Plastiki

- Kutengana kwa ufanisi: Inaweza kutenganisha kwa ufanisi flakes za chupa za PET na kofia za chupa za PP ili kuhakikisha ubora wa flakes za mwisho.

- Udhibiti wa polyolefin: Dhibiti maudhui ya polyolefin kwa ≤200-300mg/kg ili kukidhi viwango vya utumiaji tena.

- Tangi ya kuosha ya kina: Kwa flakes nyepesi za chupa za PET, tank ya kusafisha zaidi imeundwa ili kuhakikisha kujitenga kwa ufanisi.

- Kubinafsisha: Inaweza kubinafsishwa kulingana na mahitaji ya wateja na kubadilishwa kwa urahisi kwa tofauti Mistari ya kuosha PET.

Video ya Maombi ya Kutenganisha Tangi la Kuelea kwa Kuzama

Kanuni ya Kazi ya Kutenganisha kwa Plastiki ya Kuelea kwa Sink

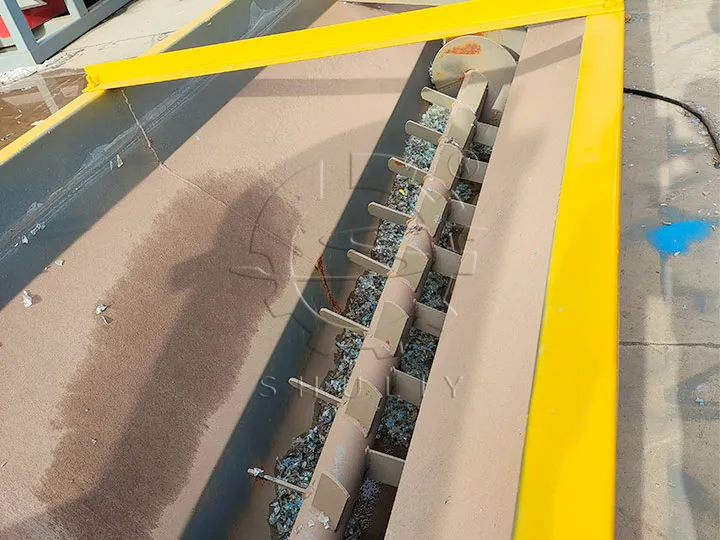

Maskinen använder vatten som medium och utnyttjar densitetsdifferensen för separation. När de blandade plaster går in i sänka och flyta separations tank, kommer PET plasten att sjunka till botten av tanken eftersom densiteten är större än vattnets, och den nedre skruven transporterar flaskflaken till nästa process; medan PP-flasklocket flyter på ytan av vattnet och avlägsnas genom utloppet på maskinens sida. På detta sätt uppnås effektiv separation av blandade plaster.

Mapendekezo ya Usanidi Kwa Tangi ya Kutenganisha ya Kuelea kwa Sink

Idadi ya mitengano ya plastiki ya kuelea inategemea kiwango cha uchafuzi wa plastiki, mahitaji maalum ya mteja, na kiasi cha uzalishaji. Kwa kawaida, mashine hii husakinishwa baada ya kipondaji kiotomatiki cha chupa ya plastiki ili kutenganisha vifuniko na lebo zilizosalia kutoka kwa chupa za PET.

Ikiwa ubora wa bidhaa ni muhimu zaidi au kiasi cha uzalishaji ni kikubwa, inashauriwa kufunga mashine moja au mbili za kuosha chupa za PET baada ya tank ya kuosha moto. Hii husafisha kwa ufanisi sabuni iliyotolewa kutoka kwenye tank ya kuosha moto, hupunguza maudhui ya PVC, na hutenganisha zaidi uchafu.

Vigezo vya Kutenganisha kwa Plastiki ya Kuelea kwa Kuzama

Ili kuzuia flakes za chupa zisizo na uzito zisiweze kuzama, na kuziepuka zifanyike wakati wa kuondoa kofia za PP, tumeongeza na kupanua tank ya kusafisha. Ifuatayo ni maelezo ya kina ya kigezo cha tanki ya kutenganisha kuelea ya kuzama.

- Urefu: 6.0 m

- Upana: 1.2m

- Urefu: 1.2 m

- Nguvu ya gari: 3kw, awamu ya tatu 380V50Hz

- Unene wa ukuta wa nje: 4 mm

- Unene wa blade: 6 mm

Mashine nyingine ya Kuosha Matambara ya PET

Förutom sänka flyta plast separationer erbjuder vårt företag också PET-flakes tvättmaskiner som varmt tvättade PET-flakes maskiner och friktionstvättare. Dessa maskiner arbetar tillsammans med andra PET-flaskåtervinningsmaskiner för att bilda en komplett PET-flasktvättlinje. Vi erbjuder också anpassade lösningar för att flexibelt konfigurera rengöringslinjen enligt kundens behov och produktionsskala för att uppnå bästa rengöringseffekt och produktionseffektivitet.