Dây chuyền sản xuất bột cao su bán tự động

Dây chuyền sản xuất bột cao su bán tự động này được thiết kế cho các doanh nghiệp tái chế lốp xe quy mô nhỏ đến vừa. Nó phù hợp…

Dây chuyền sản xuất bột cao su bán tự động này được thiết kế cho các doanh nghiệp tái chế lốp xe quy mô nhỏ đến vừa. Nó phù hợp để xử lý lốp xe ô tô, lốp xe tải và một số lốp xe công nghiệp nhẹ có đường kính lên tới 1200mm. Lốp xe thải có thể được xử lý thành hạt cao su 1–5mm hoặc bột cao su 10–40 mesh thông qua một loạt máy được cấu trúc tốt. Sản phẩm cuối cùng có thể đạt độ tinh khiết lên tới 99%, đáp ứng yêu cầu của các ứng dụng tiếp theo như sản xuất cao su tái chế và sản phẩm cao su.

Nguyên liệu thô và sản phẩm cuối

Nguyên liệu: Tất cả các loại lốp xe đã qua sử dụng (≤1200mm)

Sản phẩm cuối cùng:

- Hạt cao su (1–5mm): được sử dụng trong các đường chạy thể thao, sân chơi, lấp đầy cỏ nhân tạo, v.v.

- Bột cao su (10–40 lưới): được sử dụng cho các sản phẩm cao su, cao su tái chế hoặc nhựa đường đã được cải tiến

- Dây thép và sợi: có thể được tách ra và thu gom để tái sử dụng hoặc tái chế

Các đặc điểm chính của dây chuyền sản xuất bột cao su

- Khả năng tương thích vật liệu rộng: Phù hợp với nhiều kích thước lốp xe thông dụng

- Đầu ra linh hoạt: Có thể tùy chỉnh từ vài tấn đến hàng chục tấn mỗi ngày

- Yêu cầu lao động thấpDễ vận hành; 2–3 công nhân có thể vận hành toàn bộ dây chuyền

- Độ tinh khiết sản phẩm caoThép và sợi được tách biệt hiệu quả, đảm bảo độ tinh khiết bột cao su lên đến 99%

- Cấu trúc mô-đunThiết kế thiết bị riêng lẻ để dễ bảo trì và sửa chữa

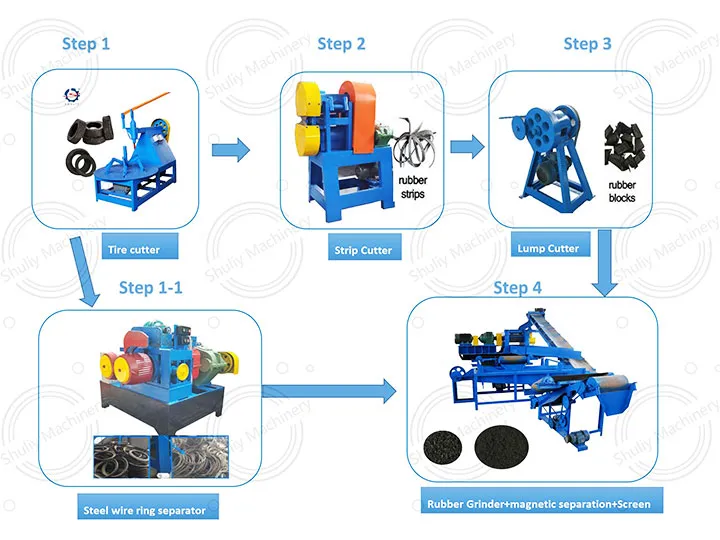

Thiết bị và chức năng

Dưới đây là các thiết bị có trong dây chuyền sản xuất bột cao su bán tự động và vai trò của chúng:

Cắt các viên bi thép từ cả hai bên của lốp xe để tạo điều kiện cho các bước tiếp theo.

Cắt lốp xe thành các dải để giảm kích thước cho quá trình xử lý tiếp theo.

Cắt các dải lốp thành các khối nhỏ hơn, chuẩn bị cho việc nghiền.

Loại bỏ hiệu quả các dây thép gắn bên trong, tăng độ tinh khiết của cao su.

- Nghiền các khối cao su thành kích thước hạt mong muốn

- Hệ thống sàng lọc phân loại kích thước hạt của bột cao su và tự động trả lại các hạt không đạt tiêu chuẩn về hệ thống nghiền để đảm bảo độ mịn đồng nhất của sản phẩm.

- Sử dụng nam châm để loại bỏ bất kỳ dây thép nào còn lại

Sử dụng phương pháp tách không khí để loại bỏ tạp chất sợi mịn và nâng cao chất lượng sản phẩm

Video làm việc của dây chuyền sản xuất bột cao su bán tự động

Các tình huống ứng dụng

Lý tưởng cho các doanh nghiệp tái chế lốp xe khởi nghiệp hoặc vừa và nhỏ, và phù hợp cho các nhà máy đang tìm cách mở rộng công suất với kiểm soát chi phí.

Giải pháp tùy chỉnh

Chúng tôi cung cấp thiết kế và hỗ trợ kỹ thuật được điều chỉnh dựa trên nguyên liệu thô, mục tiêu sản xuất và ứng dụng sản phẩm của bạn, giúp bạn đạt được việc tái chế lốp xe hiệu quả và có lợi nhuận.

Lựa chọn dây chuyền sản xuất bột cao su bán tự động phù hợp không chỉ là về thiết bị - mà còn là về hiệu quả lâu dài và lợi tức đầu tư. Với kinh nghiệm và sự hỗ trợ tận tâm của chúng tôi, chúng tôi chào đón bạn liên hệ với chúng tôi để nhận giải pháp chi tiết và báo giá.