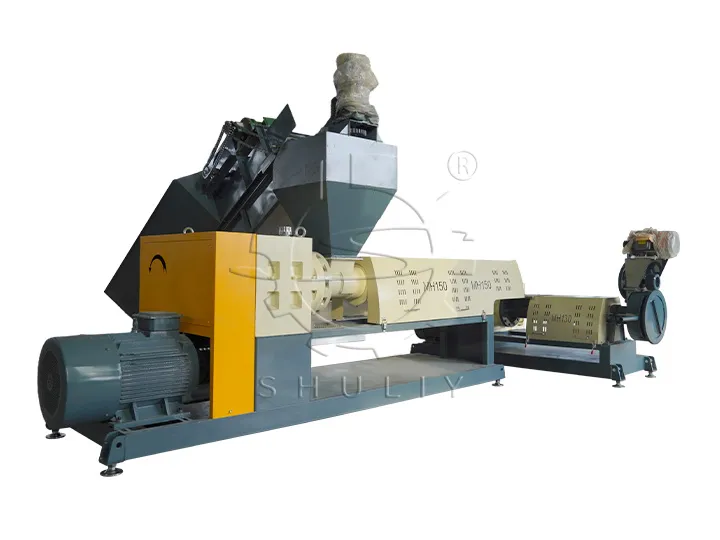

塑料造粒机

塑料造粒机是将废旧PP PE PVC PS等塑料加工成塑料颗粒的关键回收设备。该机有多种型号和配置可供选择,满足客户不同的产量要求。

塑料造粒机作为塑料回收的关键设备,在塑料回收过程中发挥着重要的作用。它可以将各种塑料废弃物,如塑料瓶、塑料袋、塑料容器等加工成粒状塑料原料,为塑料制品的再次生产提供可靠的原料来源。

舒利机械的塑料颗粒机结构稳定,操作方便,适合各种规模的生产场景。并且有多种型号,可以满足不同客户的生产需求。

我们的设备已销往许多国家,并得到了许多客户的好评,如果您有需要,请随时与我们联系。我们专业的销售经理将为您提供详细的产品介绍、报价、技术支持,确保您选择最合适的设备。同时,我们还提供安装调试服务,帮助您快速投入生产。

塑料造粒机工作视频

下面是塑料造粒的实际视频,展示了从进料、加热熔化、挤出、冷却到切割的完整过程。

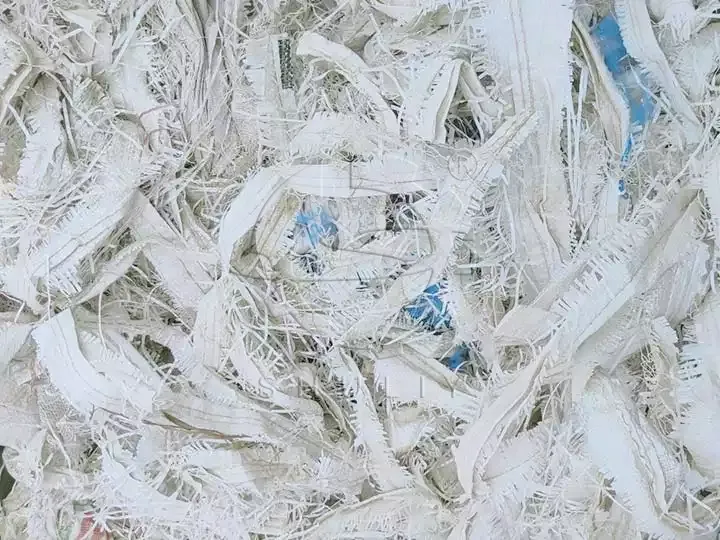

塑料回收造粒机原料

塑料造粒机是塑料造粒生产线中的关键设备,用于将PP、PE、HDPE、LDPE、PVC、PS等废塑料加工成塑料颗粒。它可以将塑料片、塑料瓶、塑料薄膜、塑料袋、塑料桶、塑料管、塑料制品生产过程中产生的边角料等加工成塑料颗粒。我们可以为您的原材料推荐合适的解决方案。

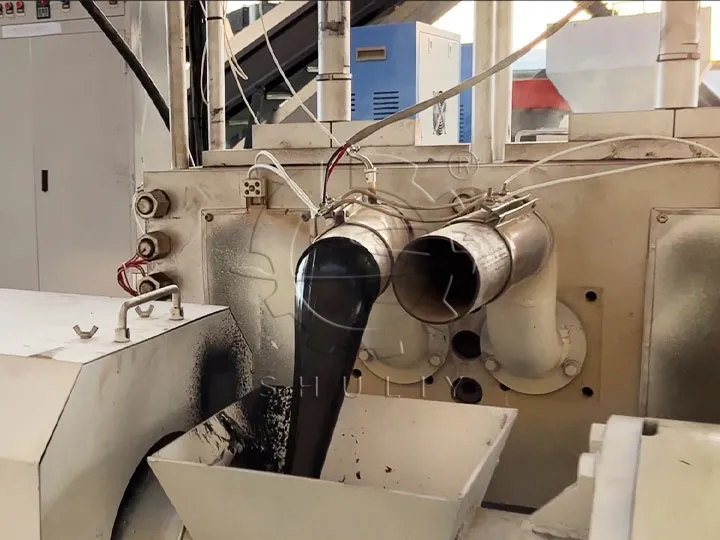

最终产品 – 塑料颗粒

通过我们的造粒机,废旧塑料经过一系列工艺处理,最终生产出高质量的塑料颗粒。这些颗粒尺寸均匀、性能稳定,可直接用于制造新型塑料制品,如包装材料、容器、管材等。我们的造粒系统不仅提高了资源的再利用,还为客户提供了优质的再生材料。

塑料回收造粒机结构

塑料颗粒机通常包括进料口、自动加料装置、减速机、加热装置、螺杆、电机和模头。这些部件协同工作,完成塑料加工的全过程。

强制送料机一般用在薄膜类材料需要加工的情况下,而硬质材料通常不需要此装置。螺杆是挤出机最重要的部件,可以调节到需要的长度。加热装置和模头有多种类型,可根据不同的加工需求进行配置。

塑料造粒机工作原理

塑料造粒机通过将废旧塑料加热熔融,然后挤出、切割,将塑料原料加工成颗粒以供再利用。工作过程中,废旧塑料从加料口进入机器,通过加热装置熔化,然后通过螺杆输送到模头,最后挤出成连续的长条状塑料。将塑料段冷却并切割以获得尺寸均匀的塑料颗粒。

造粒机的优点及特点

带除铁装置的输送带:配备除铁装置的输送带,有效防止金属杂质进入造粒过程,保证颗粒质量。

强制进料器的选择性配置:可根据不同原料的特性选择强制送料机的配置,保证原料的稳定供应,提高生产效率。

各种造粒方式:除常见的拉条造粒方式外,还可采用水环切粒方式,适应不同类型塑料的加工需求,提供更广泛的选择。

定制设计:我们的塑料造粒机型号以螺杆内径命名,长度可根据客户的具体要求定制,以满足不同的生产规模和工艺要求。

优质材料保证:螺杆采用38Lo锰钢,模具采用40Lo锰钢,保证耐磨性和使用寿命,生产性能稳定。

智能配置:根据原材料的特性,推荐合适的加热装置和模头类型,以提高生产效率和成品质量。

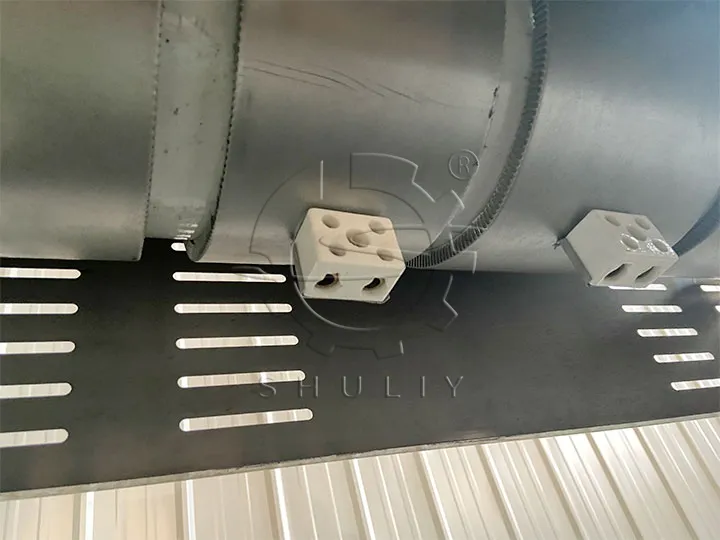

塑料造粒机的加热方法

塑料造粒机的加热方式主要有电磁加热、陶瓷加热、普通电加热等。不同的加热方式适用于不同类型的塑料和生产需要,但均能有效地将塑料加热至熔融状态。

电磁加热:该方式具有加热快、能耗低的优点,适合加热速度要求高的生产场景。

电磁加热具有温度均匀、控制精度高的特点,可有效提高生产效率。

陶瓷加热:陶瓷加热是利用陶瓷发热元件进行加热。这种加热方式具有稳定性好、耐高温、使用寿命长的特点,适用于对加热温度要求较高、需要长时间连续加热的场合。

普通电加热:普通电加热是一种常见的加热方式,通过电阻丝或热管等电热元件产生热量来加热塑料材料。该方法简单易操作,成本相对较低,适合一般塑料加工生产。

塑料造粒机模头

塑料造粒机模头是塑料颗粒生产过程中的关键部件之一,其主要作用是将加热后的熔融塑料原料成型为所需形状和尺寸的塑料颗粒。我们有电动齿轮模头、液压模头、无网排渣模头三种,客户可以根据自己的生产要求进行选择。

电动齿轮模头:电动齿轮模头是常用的模头类型。该型模头结构简单,操作方便,适合一般塑料造粒需要。优点是生产稳定、成本低。

液压模头:液压模头由液压系统驱动,控制挤出机构的运动,实现塑料颗粒的挤出。

具有挤压力大、工作平稳等优点,适用于 塑料造粒生产线 需求量大,生产规模大。

无网排渣模头:该模头的特点是无网设计,通过特殊的排渣装置将塑料原料中残留的杂质和杂质排出。

该类型模头适用于对塑料颗粒质量要求较高的场合,能有效提高生产效率和产品质量。

造粒机技术参数

| 品牌 | 舒利机械 |

| 产品 | 塑料造粒机 |

| 生产能力 | 100公斤/小时-1000公斤/小时 |

| 造粒方式 | 拉条造粒、水环造粒 |

| 加热方式 | 电磁加热、陶瓷加热、电加热 |

| 模头 | 电动齿轮模头、液压模头、无网格排渣模头 |

| 可定制性 | 可定制 |

| 拉条造粒直径 | 3mm-4mm |

| 兑换率 | 高达 2% 的消耗率仅取决于塑料原材料的质量和清洁度。 |

塑料造粒机价格

舒利机械的塑料造粒机价格合理,物有所值。我们提供多种型号和配置的塑料造粒机,以满足客户的不同需求和预算。

无论您是小型塑料回收商还是大型制造商,我们都可以提供适合您需求并确保产品质量和性能的塑料回收造粒机。同时,我们还提供灵活的定制服务,根据客户的特殊要求定制塑料造粒机,为客户提供更加个性化的解决方案。