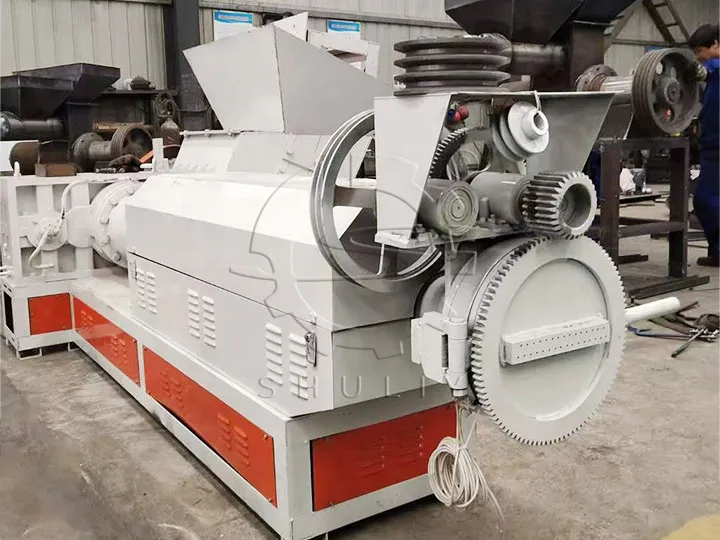

Horizontal EPS Foam Compactor

The horizontal EPS foam compactor will compress EPS foam into blocks or a higher density form for easier storage and transportation. This article describes the working principle, function, and parameters of the machine.

The horizontal EPS foam compactor is a piece of equipment used to process EPS (polystyrene) foam waste. EPS foams are commonly used as packaging and filler material, but they take up a lot of space when discarded. This machine will compress EPS foam into blocks or a denser form for easier storage and transportation while reducing the burden on landfills.

What is an EPS Foam Compactor?

The EPS foam compactor is a machine specially designed to process EPS foam waste. It transforms waste EPS foam into a more compact form for storage, transportation, and recycling through efficient compression technology. In addition to the horizontal EPS foam compactor introduced, our company also offers a vertical EPS foam compactor. Our foam compactors not only provide reliable performance and quality manufacturing processes but also offer a wide selection of specifications and configurations to meet the needs of different customers.

Working Principle of Foam Compactor

The working principle of the horizontal EPS foam compactor is based on the principle of mechanical compression, which compresses the loose foam material into high-density blocks by strong pressure for easy storage and transport. The following is its specific working process:

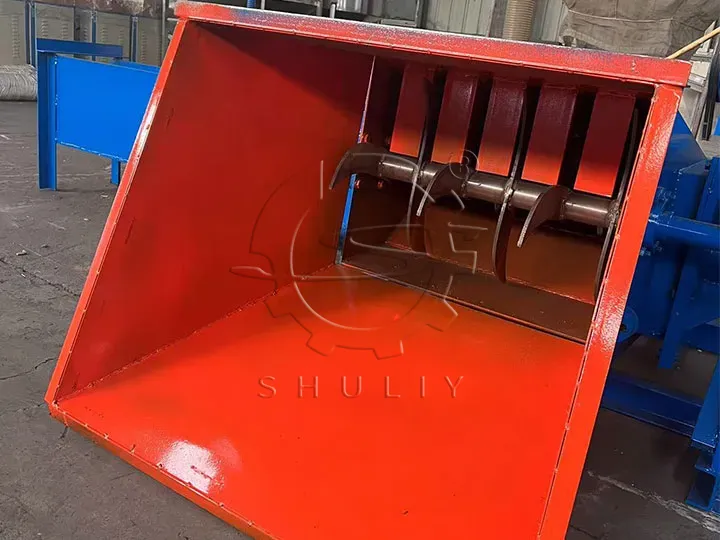

- Feeding: Waste foam materials (e.g. EPS, EPE, etc.) are put into the machine through the feeding port.

- Crushing: The crushing device breaks the larger foam material into smaller pieces to facilitate the subsequent compression process.

- The styrofoam compactor applies strong pressure to the foam and squeezes the air out of it, resulting in a significant volume reduction.

- Forming and Discharge: The compressed foam is extruded into high-density blocks and output through the discharge opening. The compressed blocks are usually of high density and neat size, which is convenient for subsequent storage and transport.

Horizontal EPS Foam Compactor Parameters

| Type | 300 | 400 |

| Machine size (mm) | 3000*1700*900 | 4600*2800*1200 |

| Inlet size (mm) | 830*760 | 870*860 |

| Capacity (KG/H) | 175 | 300 |

| Power (KW) | 15 | 22 |

EPS Foam Compactor Features

- High-efficiency compression: Adopting advanced compression technology, EPS foam waste can be compressed into high-density products, significantly reducing the volume.

- Environmental protection and energy saving: the compression process does not require the addition of chemical substances, reducing environmental pollution and meeting the requirements of environmental protection; at the same time, the energy-saving design reduces energy consumption.

- Versatility: Compactors of different specifications and capacities can be customized according to user requirements, suitable for production lines of various sizes.

- Economical: It has good cost performance, and long-term use can reduce the cost of waste disposal and bring economic benefits.

Foam Compactor Selection Advice

The following factors need to be considered when selecting a horizontal EPS foam compactor:

- Production scale: Select the appropriate foam compactor model and capacity according to the expected processing capacity.

- Technical performance: focus on the horizontal EPS foam compactor’s compression ratio, compression efficiency, degree of automation, and other performance indicators.

- Safety and reliability: Ensure that the equipment has perfect safety protection devices and stable operation performance.

- After-sales service: choose manufacturers or brands with reliable after-sales service support to ensure the long-term stable operation of the equipment.

Styrofoam Recycling Machine For Sale

We offer a variety of foam recycling solutions to meet the needs of different customers. In addition to styrofoam compactors that can be used to compress foam into blocks, we also offer EPS hot melting recycling machines that can melt foam into blocks for easy storage and transport.

In addition, our plastic foam granulators can process waste foam material into pellets that can be reused in production. No matter what type of foam recycling you need, we can provide you with efficient and reliable equipment and services. If you are interested in our foam recycling machine, please feel free to contact us.