Garis Granulasi Daur Ulang Plastik Film PP PE

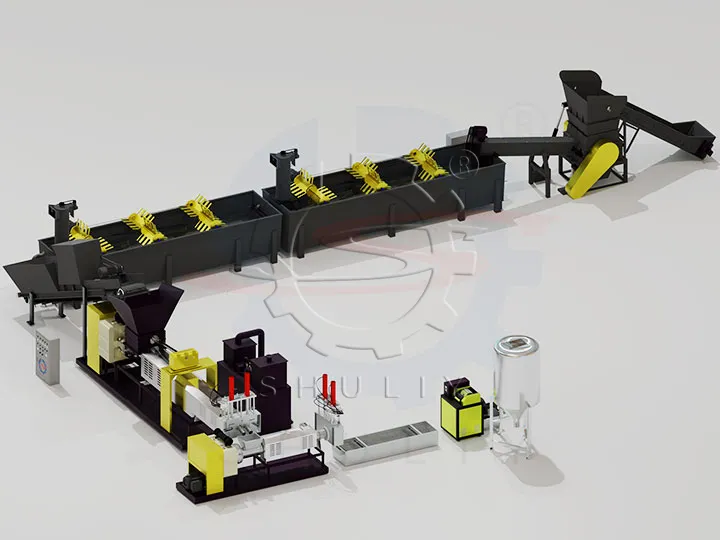

Jalur granulasi daur ulang plastik film PP PE kami adalah sejenis peralatan atau lini produksi yang digunakan untuk mengubah limbah film plastik menjadi pelet plastik. Output dari jalur daur ulang film plastik kami biasanya berkisar antara 500kg/jam hingga 2000kg/jam, dan output spesifik dapat disesuaikan dengan kebutuhan pelanggan.

Jalur granulasi daur ulang plastik film PP PE kami adalah sejenis peralatan atau lini produksi yang digunakan untuk mengubah limbah film plastik menjadi pelet plastik. Lini produksi biasanya mencakup serangkaian peralatan mekanis untuk membersihkan, menghancurkan, melelehkan, mengekstrusi, dan membuat granulasi film plastik. Proses ini secara efektif mengubah limbah film plastik menjadi bahan mentah yang dapat digunakan kembali, sehingga mengurangi pencemaran lingkungan dan melestarikan sumber daya.

Output dari jalur daur ulang film plastik kami biasanya berkisar antara 100kg/jam hingga 500kg/jam, dan output spesifik dapat disesuaikan dengan kebutuhan pelanggan. Kemampuan penyesuaian ini memungkinkan lini disesuaikan dengan skala produksi dan persyaratan yang berbeda untuk memenuhi kebutuhan pelanggan yang berbeda.

Video Lari Garis Pelet Film PP PE

Karakteristik Teknis Mesin Daur Ulang Film Plastik

- Mesin penghancur dapat diisi dengan air untuk membantu bahan film masuk ke peralatan dengan lebih baik, dan pada saat yang sama mengurangi panas gesekan pada bilah untuk memperpanjang masa pakai.

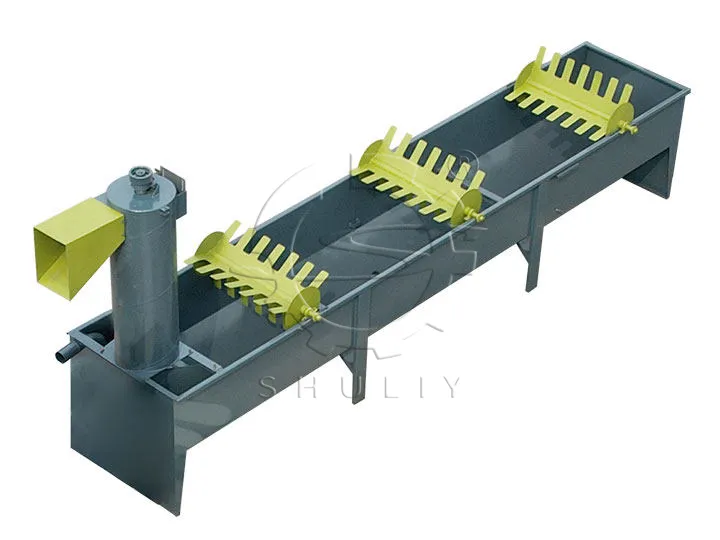

- Dilengkapi dengan Perangkat pengangkut berbentuk U untuk mencegah bahan film menggantung atau tersumbat selama pengangkutan dan meningkatkan efisiensi produksi.

- Meningkatkan kaliber lubang pembuangan tangki cuci, yang dapat dikuras dengan cepat, sehingga meningkatkan efisiensi pembersihan secara signifikan.

- Berbagai macam model mesin granulasi tersedia untuk memenuhi pelanggan dengan keluaran dan kebutuhan berbeda.

- Peralatan bantu seperti mobile silo, strip shaker, strip blower, vibrating screen, dll. disediakan untuk menjamin kualitas produk akhir.

- Seluruh lini granulasi daur ulang plastik dapat disesuaikan sesuai dengan permintaan pelanggan, dan arah lini produksi yang optimal dapat dirancang dengan menggabungkan area dan tata letak pabrik.

Bahan Baku Garis Granulasi Daur Ulang Plastik

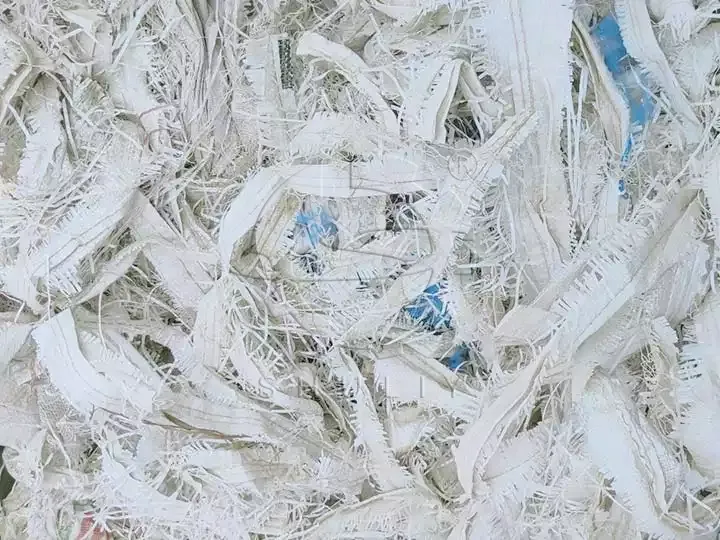

Bahan baku yang dibutuhkan untuk lini pelet film PP PE meliputi semua jenis produk limbah plastik, seperti film plastik, tas anyaman PP, kantong semen, film rumah kaca pertanian, film kemasan industri, film heat shrink, film lilitan, kantong sampah, gelembung film, dan sebagainya. Setelah dihancurkan, dibersihkan, dan dijadikan pelet, produk limbah plastik tersebut dapat diubah menjadi butiran plastik, yang dapat digunakan kembali untuk memproduksi produk plastik.

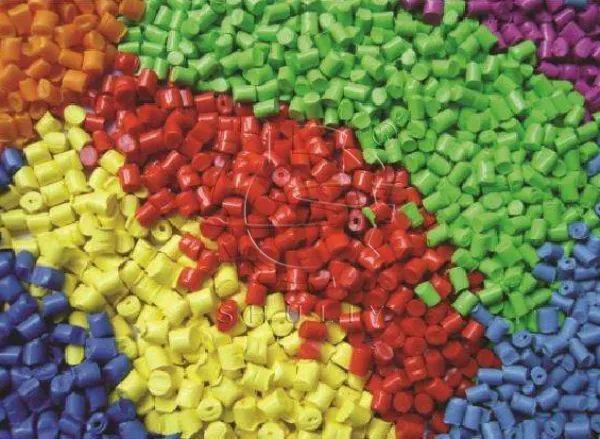

Produk Akhir-Pelet Plastik

Proses Pelet Plastik Dan Mesin Terkait

Mesin Penghancur Sampah Plastik

Pertama, film plastik bekas masuk ke mesin penghancur sampah plastik untuk dihancurkan menjadi beberapa bagian untuk selanjutnya dicuci dan digranulasi.

Peralatan ini mengadopsi bilah baja paduan untuk umur panjang dan perawatan mudah, dan ukuran layar dapat disesuaikan.

Serpihan plastik yang dihancurkan dicuci melalui tangki pencuci untuk menghilangkan kotoran permukaan, kotoran, dan residu untuk menjamin kebersihan bahan baku.

Mesin tersebut dilengkapi dengan beberapa roda pengaduk yang menggerakkan plastik ke depan saat dibersihkan. Pembukaan drainase 200 mm untuk drainase cepat dan peningkatan produktivitas. Panjangnya dapat disesuaikan.

Mesin dewatering vertikal mengekstraksi plastik yang sudah dibersihkan dari tangki pencucian dan proses dewatering menghilangkan air untuk memastikan kualitas pelet pada granulasi berikutnya.

Mesin Pelet Daur Ulang Plastik

Plastik yang telah dikeringkan dimasukkan ke dalam mesin pelet daur ulang plastik, lalu dilebur dan diekstrusi menggunakan pemanasan dan ekstrusi untuk membentuk strip plastik panjang yang berkesinambungan.

Mesin ini tersedia dengan berbagai metode pemanasan dan die head.

Tangki Pendingin Plastik

Tangki pendingin plastik terutama digunakan untuk mendinginkan dan mengeraskan strip plastik panjang yang diekstrusi dari granulator plastik. Peralatan ini terbuat dari baja tahan karat untuk memastikan ketahanan terhadap korosi dan stabilitas jangka panjang.

Butiran plastik yang didinginkan dan diawetkan dimasukkan ke dalam Pemotong Dana Plastik untuk dipotong, yang memotong potongan plastik panjang terus menerus menjadi pelet yang lebih kecil dengan panjang yang diinginkan.

Ukuran butirannya sekitar 3 mm dan dapat diatur sesuai kebutuhan.

Silo Penyimpanan Pelet Plastik

Terakhir, pelet plastik yang sudah dipotong dikumpulkan ke dalam silo penyimpanan untuk penyimpanan sementara dan dikemas untuk transportasi dan penjualan.

Dimensi silo penyimpanan butiran plastik ini juga dapat disesuaikan.

Video 3D Jalur Granulasi Daur Ulang Plastik

FAQ Garis Granulasi Daur Ulang Plastik

Jenis Film Plastik Apa yang Dapat Diproses oleh Jalur?

Garis granulasi daur ulang plastik dapat memproses berbagai jenis film plastik, termasuk LDPE, HDPE, PP, PVC dan film plastik lainnya yang biasa digunakan dalam pengemasan, pertanian, konstruksi, dan industri.

Bisakah Output Jalur Daur Ulang Film Limbah disesuaikan?

Ya, kapasitas produksi jalur granulasi daur ulang plastik dapat disesuaikan untuk memenuhi kebutuhan spesifik pengguna. Kapasitas produksi biasanya berkisar antara 500 kg/jam hingga 2.000 kg/jam, namun produsen dapat menyesuaikan peralatan untuk kebutuhan produksi yang lebih tinggi atau lebih rendah.

Bisakah Bahan Lunak dan Keras Dipelet Secara Bersamaan?

Tidak. Pelet bahan lunak dan keras secara bersamaan dapat menyebabkan butiran mudah retak sehingga menurunkan kualitas pelet. Mereka memiliki sifat dan karakteristik yang berbeda dan pengolahan secara bersamaan dapat menyebabkan pelet tidak rata, dll. Yang terbaik adalah mengolahnya secara terpisah untuk memastikan kualitas dan stabilitas butiran.

Kapan Jalur Daur Ulang Film Limbah akan dikirimkan? Bagaimana dengan purna jual?

Biasanya, tanggal pengiriman jalur granulasi daur ulang plastik adalah 20-25 hari. Kami menyediakan layanan purna jual yang komprehensif, termasuk pemasangan peralatan, commissioning, dan masalah pengoperasian.

Jalur Daur Ulang Film Limbah yang Disesuaikan

Kami menawarkan rangkaian lengkap lini pelet plastik khusus untuk memenuhi berbagai kebutuhan Anda. Anda dapat menyesuaikan tampilan dan keluaran mesin sesuai dengan kebutuhan aktual Anda dan memilih konfigurasi peralatan yang tepat.

Selain itu, kami dapat secara fleksibel menyesuaikan arah jalur granulasi daur ulang plastik sesuai dengan ukuran dan tata letak pabrik Anda untuk memastikan konfigurasi peralatan yang optimal dan efisiensi operasional. Terlepas dari skala produksi dan kondisi lokasi Anda, kami dapat merancang solusi pembuatan pelet plastik yang optimal untuk Anda.

Kasus Ekspor Mesin Daur Ulang Film Plastik

1, Sebelumnya, pelanggan dari Arab Saudi memesan jalur granulasi film plastik 1000kg/jam dari perusahaan kami, yang telah berhasil dipasang dan dioperasikan dengan bantuan teknisi kami di lokasi. Berikut ini adalah gambar instalasi di tempat.

Detail lebih lanjut dapat dilihat: Jalur Granulasi Film Plastik 1000KG/H Terpasang di Arab Saudi

2, Kami juga menyediakan solusi pencucian lembaran film LDPE untuk pelanggan di Indonesia. Pelanggan ingin mencuci dan mengeringkan kepingan film LDPE berukuran 1 cm dan mengharuskan kadar air bahan akhir kurang dari 0,5%. Kami menyesuaikan layar pengering untuk mencegah kebocoran dan melengkapinya dengan saluran pengering.

Detail lebih lanjut dapat dilihat: Solusi Jalur Pencucian Film LDPE untuk Pelanggan Indonesia

Produsen Mesin Daur Ulang Film Limbah

Sebagai produsen mesin daur ulang limbah film, kami berkomitmen untuk menyediakan teknologi canggih dan peralatan yang andal untuk mengubah limbah film plastik menjadi pelet plastik yang dapat digunakan kembali. Peralatan kami terbuat dari bahan berkualitas tinggi dan teknologi canggih untuk memastikan kinerja yang stabil dan andal, efisiensi tinggi, dan penghematan energi. Baik itu dari desain hingga manufaktur atau layanan purna jual, kami selalu berorientasi pada kebutuhan pelanggan dan memberikan solusi khusus untuk pelanggan kami, jika perlu, Anda dapat meninggalkan informasi Anda pada formulir di situs web kami dan kami akan menghubungi Anda pada waktunya.