Mesin Daur Ulang Sampah Plastik Diekspor Ke Pantai Gading

Baru-baru ini, perusahaan kami telah berhasil menjalin kerjasama dengan pelanggan dari Pantai Gading dalam bidang plastik bekas…

Baru-baru ini, perusahaan kami telah berhasil menjalin kerjasama dengan pelanggan dari Pantai Gading pada mesin daur ulang sampah plastik. Kerjasama ini tidak hanya menonjolkan kekuatan teknis kami di bidang peralatan daur ulang plastik, namun juga menjadi langkah kokoh bagi kami untuk mengembangkan pasar internasional. Artikel ini akan memperkenalkan secara detail latar belakang, proses, dan hasil kerja sama ini.

Latar Belakang dan Tantangan Klien

Pelanggan telah lama berkecimpung di industri daur ulang plastik dan telah memiliki lini produksi yang operasional. Namun, peralatan pelanggan yang ada mempunyai beberapa masalah yang sangat mempengaruhi efisiensi produksi. Untuk meningkatkan produksi dan mengatasi kekurangan peralatan yang ada, pelanggan memutuskan untuk mencari mesin daur ulang sampah plastik baru yang lebih efisien dan andal.

Pada awal kerja sama, manajer penjualan kami melakukan komunikasi mendalam dengan pelanggan untuk memahami secara detail masalah peralatan pelanggan yang ada dan kebutuhan spesifik mereka akan mesin daur ulang sampah plastik baru. Pelanggan menginginkan peralatan baru tersebut dapat memperluas produksi sekaligus menghindari kegagalan dan inefisiensi yang dihadapi pada peralatan yang sudah ada.

Solusi Khusus & Kunjungan Pelanggan

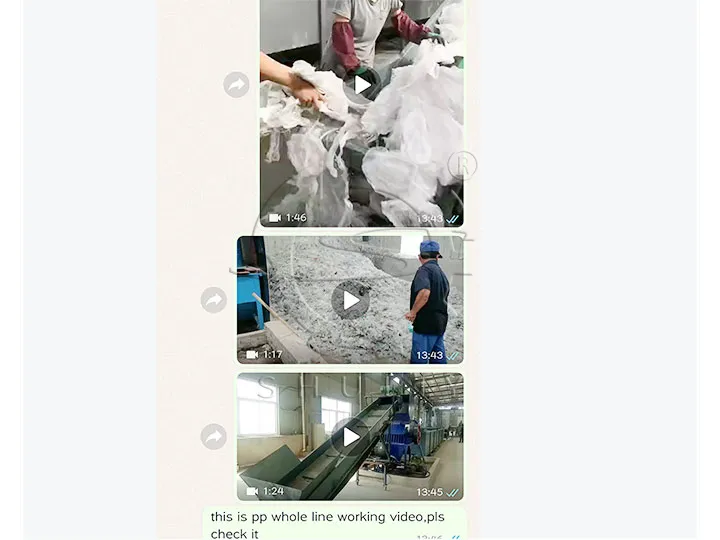

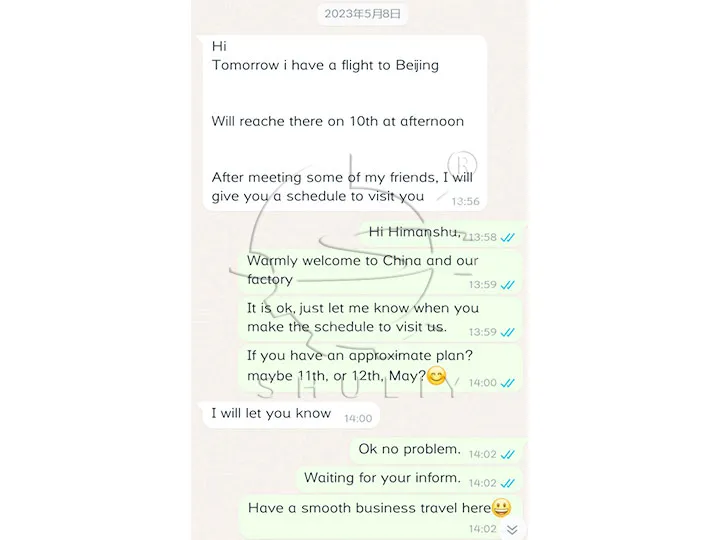

Melalui komunikasi dengan pelanggan, kami memahami bahwa bahan baku pelanggan adalah PP HDPE, dan ingin memprosesnya menjadi butiran plastik. Sesuai dengan kebutuhan pelanggan, kami membuat solusi terperinci dan memperkenalkan keunggulan teknis serta jaminan kualitas peralatan kami. Pelanggan menunjukkan minat besar pada peralatan kami dan memutuskan untuk datang ke perusahaan kami untuk kunjungan langsung. Selama kunjungan pelanggan, kami menerima mereka dengan hangat dan mengatur kegiatan kunjungan serta demonstrasi peralatan.

Konfirmasi Kerja Sama

Melalui komunikasi tatap muka dan demonstrasi pengoperasian peralatan sebenarnya, kami lebih jauh menunjukkan kepada pelanggan kami keunggulan efisiensi tinggi, daya tahan, dan pengoperasian mesin daur ulang sampah plastik yang mudah. Sikap profesional dan kinerja peralatan kami memenangkan pengakuan tinggi dari pelanggan. Pada akhirnya, pelanggan sangat puas dengan peralatan dan layanan kami, dan segera melakukan pemesanan setelah kembali ke China.

Detail Mesin Daur Ulang Sampah Plastik

| Barang | Spesifikasi |

| Mesin Penghancur Plastik | Model: SLSP-600 Tenaga motor: 30 kW Kapasitas: 600-800kg/jam 10 buah pisau Bahan pisau: 60Si2Mn |

| Mesin Cuci Scrap Plastik+Tabung Pemanas | Tenaga motor: 7,5kw Dimensi: 5,0m1,4m1,6m Diameter: 0,6m*2 Ketebalan pisau: 10mm Ketebalan dinding luar: 4mm Bahan: Q235 Daya pemanas: 60kw |

| Dehidrator Pengangkat Otomatis | Tenaga motor: 7,5kw Dimensi: 2,6m*0,7m Diameter: 0,5m Berat: 450kg Ketebalan pisau: 6mm Ketebalan dinding luar: 4mm Bahan: Q235 |

| Tangki Cuci Plastik | Tenaga motor: 4kw Dimensi: 4.51.21.3 Kekuatan motor roda gigi: 1,5kw Berat: 1200kg Ketebalan pisau: 6mm Ketebalan dinding luar: 3mm Bahan: Q235 |

| Mesin Dewatering Horisontal | Kekeringan: 98% Tenaga motor: 15kw Dimensi: 2,5m*1,0m Layar: terbuat dari baja tahan karat 304 Ketebalan pisau: 10mm Ketebalan spindel: 8mm |

| Mesin Pembuat Graule Plastik | Mesin pembuat pelet inang Model: SL-150 Daya: 37kw 2.3 sekrup Metode Panas: pemanasan keramik Peredam gigi yang diperkeras Mesin pembuat pelet kedua Model: SL-125 Daya: 11kw sekrup 1,3m Metode pemanasan: pemanasan cincin pemanas |