Solusi Jalur Pencucian Film LDPE Untuk Pelanggan Indonesia

Jalur pencucian film LDPE yang sangat efisien disesuaikan untuk memenuhi kebutuhan pelanggan di Indonesia….

Jalur pencucian film LDPE yang sangat efisien disesuaikan untuk memenuhi kebutuhan pelanggan di Indonesia. Pelanggan memiliki pabrik pembuatan pelet plastik, dan pembelian ini mencakup mesin pencuci dan pengering sisa plastik yang dirancang untuk mencuci dan mengeringkan potongan film LDPE berukuran 1 cm secara menyeluruh. Melalui komunikasi terperinci, kami merancang solusi eksklusif bagi pelanggan untuk memastikan bahwa kadar air bahan olahan mereka kurang dari 0,5%.

Analisis Kebutuhan pelanggan

Pelanggan menginginkan pembersihan dan pengeringan chip film LDPE secara menyeluruh untuk memastikan kualitas produk akhir. Oleh karena itu, mereka memerlukan produk yang dapat membersihkan dan mengeringkan serpihan plastik secara efektif. Persyaratan khusus termasuk:

- Mesin cuci film plastik yang menghilangkan kotoran dan kotoran dari film secara menyeluruh

- Mesin dewatering serpihan plastik mampu menurunkan kadar air serpihan hingga kurang dari 0,5 persen

- Pastikan pecahan tidak hilang selama pemrosesan, khususnya mencegah pecahan kecil keluar melalui saringan

Solusi yang Disesuaikan

Berdasarkan spesifikasi bahan baku dan persyaratan yang diberikan oleh pelanggan, kami merancang solusi yang mencakup mesin cuci film plastik, mesin dewatering serpihan plastik, dan saluran pengeringan khusus. Untuk menghindari kebocoran pecahan kecil, kami telah memasang layar khusus di pengering untuk memastikan bahwa semua bahan dapat menyelesaikan proses pengeringan dengan lancar.

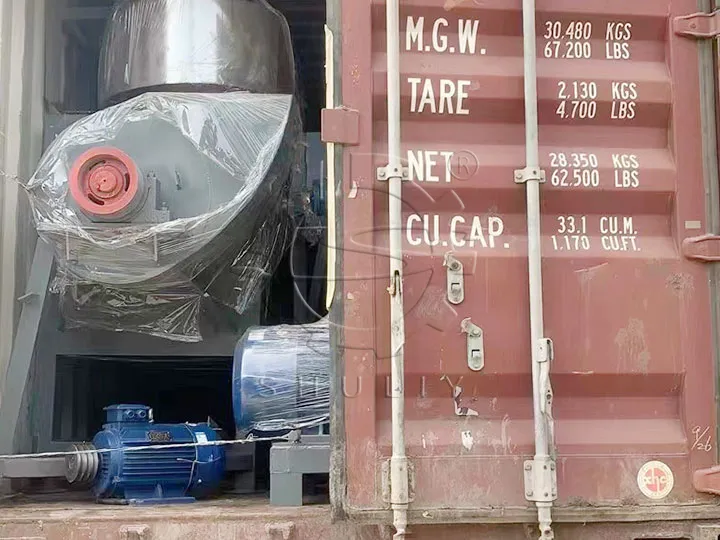

Pengiriman Jalur Pencucian Film LDPE

Lini pencucian film LDPE yang disesuaikan untuk pelanggan Indonesia tidak hanya memenuhi standar tinggi pelanggan untuk hasil pembersihan dan pengeringan, tetapi juga meningkatkan efisiensi produksi melalui desain hemat energi dan solusi yang disesuaikan. Kami akan terus mendedikasikan diri untuk menyediakan peralatan dan solusi berkualitas tinggi kepada pelanggan kami, jika Anda tertarik, Anda dapat meninggalkan pesan di situs web kami.