Mesin Baling Plastik

Mesin baling plastik adalah peralatan profesional yang dirancang untuk mengompresi dan mengemas berbagai limbah plastik atau bahan lainnya secara efisien. Pelanggan kami sebagian besar digunakan untuk baling botol PET dan tas anyaman. Artikel ini adalah pengenalan rinci tentang mesin, termasuk aplikasi, prinsip kerja, dan sebagainya.

Mesin baling plastik adalah peralatan profesional yang dirancang untuk mengompresi dan mengemas berbagai limbah plastik atau bahan lainnya secara efisien. Ini menggunakan teknologi hidrolik untuk memampatkan sampah menjadi balok dengan cepat dan efisien, sehingga mengurangi ukurannya secara signifikan untuk transportasi dan penyimpanan.

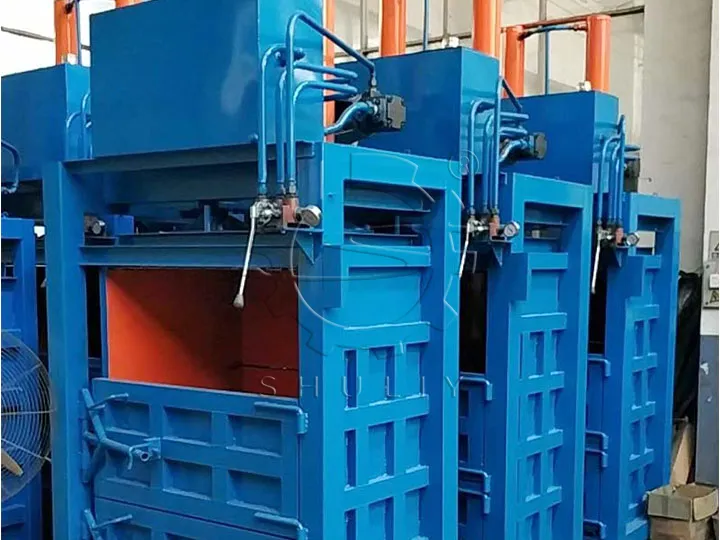

Kami terutama menyediakan dua jenis mesin baler daur ulang plastik: horizontal dan vertikal. Mereka cocok untuk skenario daur ulang yang berbeda, dan pelanggan dapat memilih model yang paling sesuai sesuai dengan kebutuhan dan hasil spesifik mereka.

Penerapan Mesin Baler Plastik

Mesin press plastik sangat serbaguna dan dapat diterapkan karena dapat menangani tidak hanya berbagai produk plastik tetapi juga berbagai jenis limbah seperti karton bekas, botol PET, drum minyak, kantong tenun, pakaian bekas, tekstil, wol, kapas, jerami dan sebagainya. Pada saat yang sama, mesin press plastik biasanya sangat dapat disesuaikan dan dapat disesuaikan dengan kebutuhan pelanggan dan skenario aplikasi tertentu untuk memastikan hasil press terbaik dan pengalaman pengguna.

Video Kerja Mesin Baling Plastik

Prinsip Kerja Baler Plastik

- Pemuatan material: Pertama, sampah plastik dimasukkan ke dalam ruang baling untuk dipadatkan.

- Mekanisme pemadatan: Komponen inti baler plastik adalah mekanisme pemadatannya, yang biasanya berupa silinder atau pelat hidrolik yang kuat. Mekanisme ini memberikan tekanan yang luar biasa pada sampah plastik, sehingga secara efektif mengurangi volume dan meningkatkan kepadatannya.

- Proses bundling: Setelah sampah plastik dipadatkan, proses bundling dimulai. Bundel diikat dengan aman menggunakan bahan pengikat seperti kawat, benang, atau pengikat plastik. Pembungkusan yang hati-hati ini memastikan bale tetap utuh selama penanganan, pengangkutan, dan daur ulang berikutnya.

- Ejeksi dan Penghapusan: Bale akhir dikeluarkan dari ruang baling, siap untuk diproses selanjutnya atau diangkut ke fasilitas daur ulang.

Klasifikasi Mesin Baler Daur Ulang Plastik

Baler vertikal dan baler horizontal adalah dua jenis peralatan baling plastik umum yang berbeda dalam konstruksi dan penggunaannya.

Baler Vertikal

Komponen utama baler vertikal disusun secara vertikal membentuk ruang baling vertikal yang biasanya lebih sempit dan tinggi. Fitur struktural ini membuatnya cocok untuk menangani material bervolume lebih kecil seperti botol plastik, tas anyaman, dll., dan dapat bermanfaat dalam skenario di mana pemadatan yang efisien diperlukan untuk menangani limbah plastik dalam volume kecil.

Daftar Parameter

Berikut adalah informasi parameter beberapa model baler vertikal untuk referensi Anda.

| Model | SL40QT | SL80QT | SL120QT | SL150QT |

| Tenaga hidrolik | 40Ton | 80Ton | 120Ton | 150Ton |

| Ukuran kemasan (LWH) | 720*720*300-1600mm | 1100*800*300-2000mm | 1100*1100*300-2100mm | 1100*1100*300-2100mm |

| Ukuran pembukaan umpan | 1000*720mm | 1500*800mm | 2000*1100mm | 2400*1100mm |

| Kemampuan | 1-3T/jam | 4-7T/jam | 9-12T/jam | 12-15T/jam |

Baler Horisontal

Ruang baling pada baler horizontal ditempatkan secara horizontal, sehingga menciptakan ruang baling horizontal yang biasanya lebih lebar dan pendek. Fitur struktural ini membuatnya cocok untuk menangani material berukuran besar seperti lembaran plastik, drum minyak, kotak kardus, sedotan, dll. Produk ini dapat unggul dalam skenario di mana limbah plastik berukuran besar perlu ditangani.

Daftar Parameter

| Model | SL-120 | SL-160 | SL-180 | SL-200 |

| Kekuatan | 22kw, 3HP, 380V | 30kw+4KW, 3HP, 380V | 37kw+4KW, 3HP, 380V | 45kw+4KW, 3HP, 380V |

| Daya dorong nominal utama | 1200KN | 1600KN | 1800KN | 2000KN |

| Ukuran makan | 1650mm*1100mm | 1650mm*1100mm | 2000mm*1100mm | 2000mm*1100mm |

| Ukuran bale | 1100*900mm | 1100*1250mm | 1100*1300mm | 1100*1400mm |

| Kapasitas | 4-7bal/jam | 5-8bal/jam | 6-9bal/jam | 8-10bal/jam |

Pelanggan Tanzania Memesan Lima Mesin Baling Hidraulik

Seorang pelanggan Tanzania memesan lima mesin baling hidrolik untuk limbah baling di perusahaan kami. Modelnya 60T, dan ukuran bale model ini adalah 600*1120mm, 2-3 bal per jam.

Lebih banyak detail kasus: Pengelolaan Limbah Tanzania Ditingkatkan Dengan Mesin Press Hidrolik

Mesin Terkait: Pembuka Bale Plastik

Selain mesin press plastik yang kami tawarkan, kami juga menawarkan pembuka bale plastik, yang dirancang khusus untuk membuka blok plastik yang dibundel dalam mesin press. Mesin ini dengan cepat memecah blok plastik yang dibundel sehingga dapat dimasukkan dengan lancar ke dalam jalur daur ulang plastik. Peralatan dalam segmen ini memastikan bahwa proses daur ulang plastik efisien dan berjalan dengan lancar.