プラスチック製洗浄槽

プラスチック洗浄タンクの目的は、破砕されたプラスチック廃棄物を徹底的に洗浄し、表面から汚れ、砂、その他の不純物を効果的に除去することです。この記事では主に本機の用途、構造、パラメータについて説明します。

プラスチック洗浄槽は、プラスチックリサイクル洗浄工場の中核設備の一つとして、廃プラスチックのリサイクルプロセスにおいて重要な役割を果たしています。破砕されたプラスチック廃棄物を徹底的に洗浄し、表面に付着した土、砂、その他の不純物を効果的に除去し、その後の加工ステップに清潔な原材料を提供するように設計されています。

プラスチック洗浄槽の紹介

これらのプラスチックフィルム洗濯機は、通常、長期にわたる安定した動作を保証するために、強くて耐久性のある炭素鋼プレートで作られています。フレキシブルな構造設計となっており、お客様のニーズに合わせて幅広い機種をお選びいただけます。ビニール袋洗濯機は、比重が軽いため水に浮く可能性があるため、PP PE 素材の洗浄に適しています。

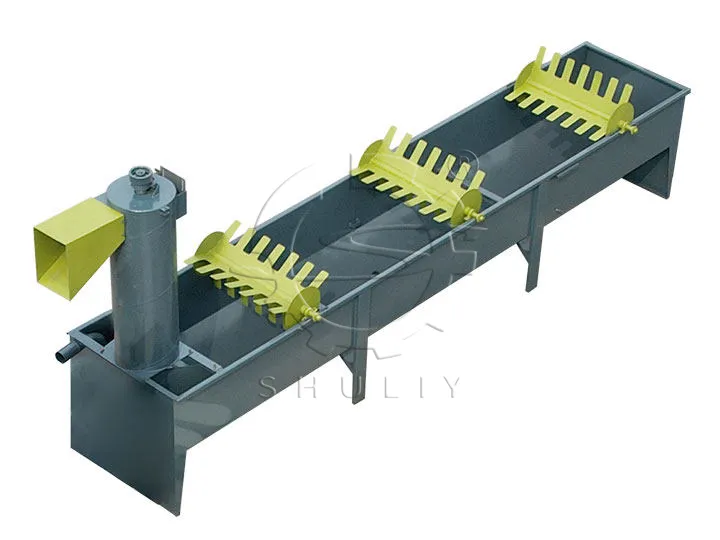

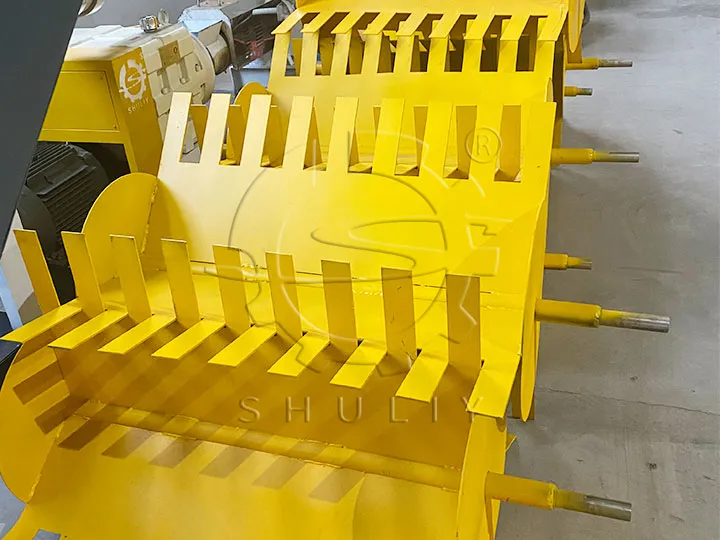

タンクには、回転および撹拌する複数の混合ギアが装備されており、水面上のプラスチックの破片を均一に分散させ、継続的に移動させることで、廃棄物をタンク内で一方の端からもう一方の端まで移動させ、総合的な洗浄効果を実現します。

ビニール袋洗濯機のメリット

- 効率的な洗浄:最適化された設計により、プラスチック洗浄タンクはプラスチック表面の汚れや不純物を効果的に除去し、洗浄効率を向上させることができます。

- 大口径排水:200mmの大口径排水口設計により、排水速度が向上し、洗浄時間が短縮され、全体的な生産効率が向上します。

- 頑丈で耐久性:炭素鋼素材で作られた洗濯機は、耐食性と耐摩耗性に優れており、長期間安定して動作できます。

- 優れた適応性: プラスチック洗浄タンクは顧客のニーズに応じてカスタマイズでき、さまざまなプラスチック洗浄シナリオに適用でき、さまざまな生産ラインの要件を満たします。

プラスチックフィルム洗浄機の応用ビデオ

PP PE プラスチック洗浄タンクの応用

PP PEプラスチック洗浄タンクは、プラスチックリサイクル洗浄プラントで広く使用されており、農業用フィルム、織布袋、シュリンクラップ、その他のフィルムプラスチックを効果的に洗浄でき、プラスチックフレークの洗浄にも適しています。

設備は顧客の特定のニーズに応じて柔軟に構成できます。原料が比較的きれいな場合は、プラスチックフィルム洗浄機を 1 台だけ設置できます。お客様が最終製品の品質に対するより高い要求を持っている場合、または原材料が汚れている場合は、プラスチック製の洗浄タンクを 2 つ装備するか、洗浄タンクの長さを長くすることを検討できます。この柔軟性により、当社の装置はさまざまな顧客のニーズを満たすことができ、プラスチックのリサイクルおよび洗浄プロセスに効率的で信頼性の高いソリューションを提供します。

プラスチックフィルム洗浄機の構造

プラスチック製洗浄槽の構造はシンプルかつ堅牢に設計されており、丈夫で耐久性のある炭素鋼板で作られています。全体は、いくつかの撹拌ホイール、水タンク、モーター、および 2 つの排水管で構成されています。撹拌ホイールが回転してプラスチック部品を混合および洗浄し、タンクのもう一方の端までスムーズに搬送します。機械の長さをカスタマイズして、さまざまな出力のさまざまな生産ラインに完全に適応できるようにすることができます。

当社のビニール袋洗濯機の排水口は大きな直径で設計されており、他の製品と比べてアップグレードされていることに注目する価値があります。生産効率を高めるため、排水口を200mmに延長し、より早く排水できるようにしました。

プラスチックチップ洗浄機のパラメータ

- タイプ: SL-150

- 能力: 1000kg/h

- 長さ: 15-20m

- 回転ホイールの数: 10

- 2つの車輪間の距離: 1.5-2m

- 排水口径:200mm

- カスタマイズ: カスタマイズのサポート

上記はポリ袋洗濯機の標準モデルのパラメータです。また、小容量用には5m洗浄槽、大容量用には30m洗浄槽を用意し、幅広いリサイクルニーズに対応します。

プラスチックフィルム洗浄機の購入についてはお問い合わせください

プラスチックフィルム洗浄機の購入にご興味がおありでしたら、お気軽にお問い合わせください。当社では、プラスチックフィルムを効率的に洗浄できる、幅広いモデルとサイズの機械を提供しています。さらに、プラスチックチップの洗浄、破砕、ペレット化など、さまざまな顧客のニーズを満たすための、完全なPP PEフィルムペレット化ラインも提供しています。お問い合わせをお待ちしております。最適なソリューションとサービスを提供させていただきます。