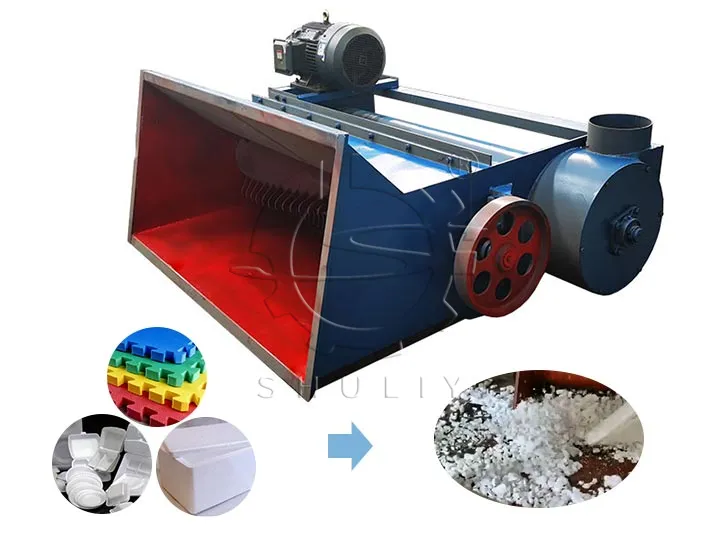

ماكينة تقطيع الرغوة EPS

إن آلة تقطيع رغوة EPS عبارة عن آلة مناسبة لسحق نفايات رغوة EPS مثل الصناديق والحاويات المعزولة. توضح هذه المقالة وظيفة هذا الجهاز وتطبيقه ومواصفاته.

تعد آلة تقطيع الرغوة EPS حلاً فعالاً وموثوقًا عند التعامل مع صناديق الغداء التي تستخدم لمرة واحدة، والصناديق المعزولة، وبطانات الرغوة للإلكترونيات، ومنتجات رغوة النفايات الأخرى. تم تصميم هذه الآلة لسحق منتجات رغوة النفايات إلى قطع صغيرة للمعالجة أو النقل أو التكوير اللاحقة.

مزايا تقطيع الستايروفوم

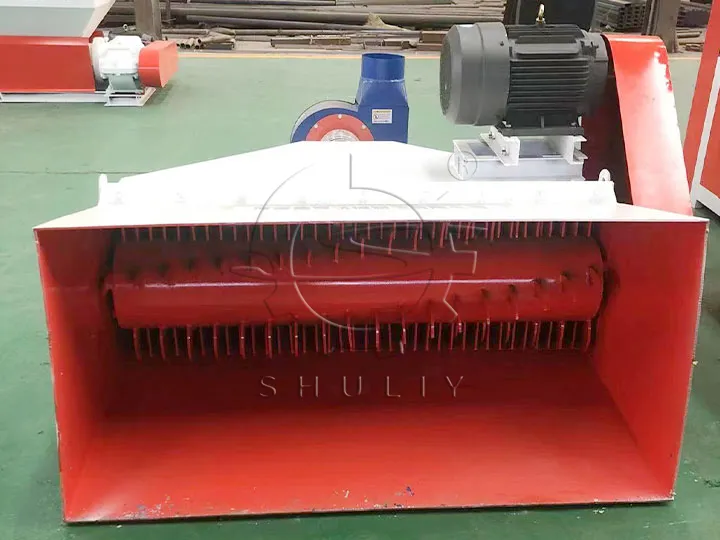

- تصميم أفقي، فتحة التغذية تكون متسقة مع الأرضية وسهلة التشغيل.

- الشفرات مصنوعة من فولاذ قياس 45 لضمان المتانة ومتوفرة في مجموعة متنوعة من أنماط الشفرات.

- يمكن تخصيص أبعاد الماكينة وأحجام المدخل من أجل التكيف المرن مع المتطلبات.

- يتم توصيل المخرج بمنفاخ وأنابيب لنقل الرغوة المكسرة بكفاءة إلى محبب EPS أو مكثف الرغوة.

لماذا تحتاج إلى سحق؟

عادةً ما توجد منتجات رغاوي النفايات في كتل أكبر، ولا يشغل التخلص المباشر أو النقل مساحة فحسب، بل إنه أيضًا غير فعال. تساعد عملية التكسير هذه على تقليل حجم النفايات وتسهل التخزين والنقل مع توفير ظروف أكثر ملاءمة لإعادة الاستخدام أو إعادة التدوير لاحقًا. بالإضافة إلى ذلك، بسبب الحجم الكبير لرغوة EPS، يجب سحقها إلى قطع صغيرة قبل التحبيب.

المواد الخام لآلة تكسير الرغوة

آلة تمزيق رغوة EPS مناسبة لمجموعة واسعة من منتجات الرغوة بما في ذلك، ولكن لا تقتصر على، صناديق الغداء ذات الاستخدام الواحد، والصناديق المعزولة، ومواد التعبئة الرغوية للمنتجات الإلكترونية، والرغوات الزخرفية. سواء كانت الرغوة مصنوعة من البوليسترين (EPS) أو البولي بروبيلين (EPP) أو البولي إيثيلين (EPE)، يمكن سحقها ومعالجتها بفعالية.

كيف يتم تطبيق آلة تقطيع الرغوة EPS؟

تتمتع آلة تمزيق الفوم بتطبيقات متعددة في عملية إنتاج إعادة التدوير. بعد السحق، يمكن نقل الرغوة إلى مكثف الرغوة الموجود خلف الكسارة. هنا، يتم إذابة الرغوة المكسورة وإخراجها، مما يوفر مساحة التخزين ويُسهل النقل. بالإضافة إلى ذلك، لتلبية احتياجات أولئك الذين يرغبون في تكوير نفايات الرغوة البلاستيكية، يمكن تكوين آلة تكوير الرغوة البلاستيكية خلف آلة سحق الرغوة.

فيديو عمل آلة تقطيع الستايروفوم

مواصفات آلة تقطيع الرغوة EPS

| نموذج | 800 | 1000 | 1200 | 1500 |

| حجم المدخل (مم) | 800*600 | 1000*600 | 1200*600 | 1500*800 |

| الطاقة (كيلوواط) | 5.5 | 5.5 | 7.5 | 11 |

| السعة (كجم/ساعة) | 250-300 | 300-350 | 400-450 | 450-500 |

اتصل بنا

إذا كنت مهتمًا بآلة تقطيع الرغوة EPS أو لديك أي أسئلة، فلا تتردد في الاتصال بنا. سنكون سعداء بتزويدك بمزيد من المعلومات والحلول المخصصة. علاوة على ذلك، فإننا نقدم أيضًا آلات إعادة تدوير الستايروفوم الأخرى، بما في ذلك ضاغطات الستايروفوم، ومحببات EPE، وآلات صهر الستايروفوم، وما إلى ذلك.

يمكن لهذه الآلات معالجة أنواع مختلفة من المواد الرغوية بشكل فعال وتعزيز كفاءة إعادة التدوير. يتم استخدام ضاغطات الرغوة لضغط الرغوة إلى كتل مدمجة لسهولة التخزين والنقل. تم تصميم كريات EPE خصيصًا لمعالجة رغوة EPE إلى كريات معاد تدويرها؛ ويمكن لآلات الصهر الساخن تسخين الرغوة وإذابتها للمعالجة اللاحقة. من خلال التنسيق بين المعدات المختلفة، نحن نقدم لعملائنا حلاً شاملاً لإعادة تدوير الرغوة.