Fiber Opening Machine

In the fiber recycling and processing industry, the fiber opening machine plays a vital role. As one of…

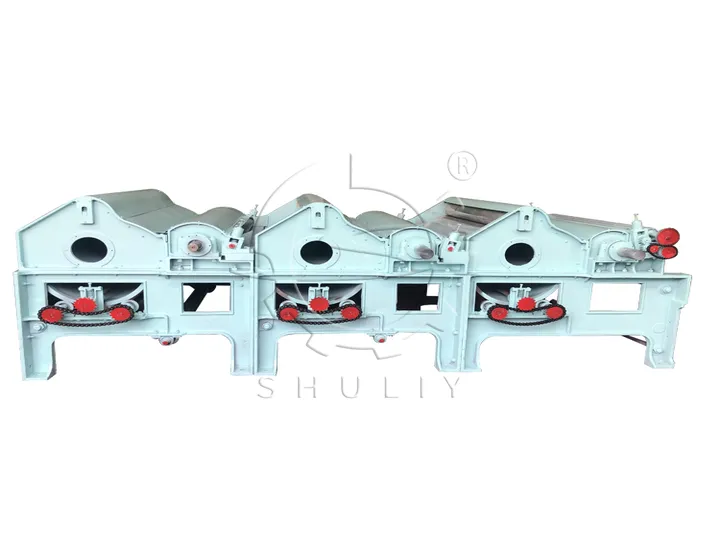

In the fiber recycling and processing industry, the fiber opening machine plays a vital role. As one of the specialized machines under Shuliy Plastic Recycling Machinery, this equipment is specifically designed to loosen compressed or entangled short fibers, restoring their fluffy state and preparing them for further processing.

Our fiber carding machines are suitable for various types of fiber materials, with a single-machine capacity ranging from 100 to 350 kg per hour, making them ideal for small to medium-sized production lines. The number of opening rollers can be selected based on the type of material and opening requirements. We offer multiple models and configurations with customization options better to match the customer’s processing needs and factory layout.

What Is the Function of a Fiber Opening Machine?

The primary function of a cotton carding machine is to loosen compressed or entangled fibers, restoring them to a fluffy and uniform state for further processing. Through high-speed rotating opening rollers, the machine effectively removes impurities and clumps from the fibers, improving material usability and consistency.

The opened fibers can be used in various applications such as filling, regenerated cotton production, and nonwoven fabric manufacturing, making the machine an essential part of fiber recycling and reprocessing workflows.

Materials Suitable for the Fiber Carding Machine

The fiber opening machine is suitable for a wide range of soft fiber materials, including polyester staple fiber, cotton fiber, nonwoven fabric scraps, waste cloth, yarn, thread, fabric, flax, polyester, fur, silk, wool, textile waste, regenerated fibers, coconut fiber, and more. After opening, these materials can be used for filling, recycling, or other textile applications, effectively improving raw material utilization.

Features of the Textile Carding Machine

- High Efficiency: Equipped with powerful motor, offering 15%–20% higher opening efficiency compared to similar products.

- Fully Enclosed Design: Comes with safety protection devices for safer and more reliable operation.

- Durable Structure: Made of high-quality steel for enhanced durability and long service life.

- Easy to Operate: Simple operation—just place the material at the feeding inlet, reducing labor intensity.

- Wide Material Compatibility: Suitable for various types of fiber materials with strong adaptability.

Technical Specifications of the Fiber Opening Machine

Our fiber carding machines offer a capacity range of 100 to 350 kg per hour, making them suitable for small to medium-scale production. The machines are available in single-roller, double-roller, and multi-roller configurations, and can also be customized according to the type of material and opening requirements to ensure optimal performance and capacity matching.

Related Equipment – Fiber Cutting Machine

Before the fiber opening process, many materials such as waste fabric, long fibers, or nonwoven textiles need to be cut to a manageable length. The fiber cutting machine, as a key part of the fiber recycling machine system, is used to cut raw materials into short fibers suitable for opening, thereby improving overall processing efficiency. This machine is often used in combination with the fiber opening machine to form an efficient fiber recycling workflow.

Contact us for more details and a quote!

Choosing Shuliy’s fiber opening machine means choosing more than just a piece of equipment—it’s selecting a mature and reliable recycling solution. We offer equipment customization, technical commissioning, and complete line design services to help you achieve an efficient recycling process from cutting to opening to baling.

Feel free to contact us via our website, email, or WeChat. Based on your material type and capacity requirements, we will recommend the most suitable system configuration and provide professional quotations and implementation plans.