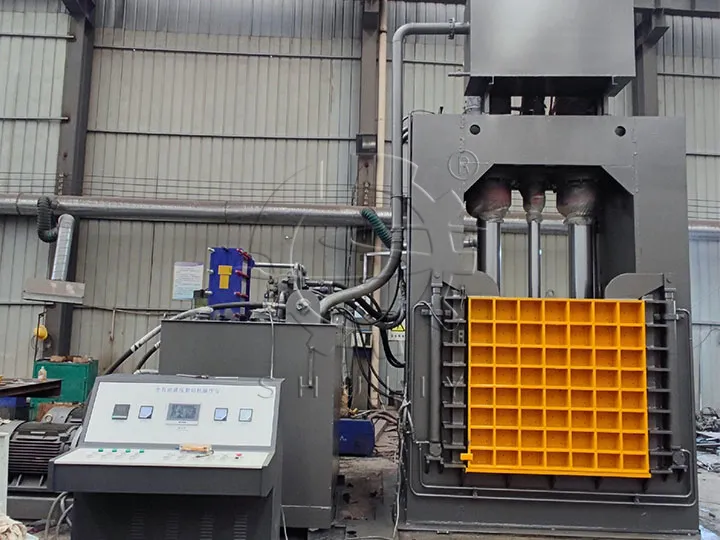

Gantry Shear For Scrap Metal

A gantry shear for scrap metal is a heavy-duty cutting machine designed for processing and downsizing various types…

A gantry shear for scrap metal is a heavy-duty cutting machine designed for processing and downsizing various types of scrap metal in recycling yards, steel mills, and metal processing plants. With a powerful hydraulic system and robust structure, this equipment can cut large steel plates, steel bars, H-beams, angle steel, and bundled scrap into smaller, manageable pieces, making transportation and smelting more efficient.

For businesses involved in metal recycling or scrap processing, choosing the right gantry shear can significantly improve cutting efficiency, reduce labor costs, and increase the value of processed scrap.

What is a Gantry Shear for Scrap Metal?

A gantry shear machine is a type of hydraulic metal shear that uses a strong downward cutting force to shear large and heavy scrap. It features a gantry-style frame for stability and is capable of handling thick and bulky materials that traditional metal cutting machines cannot process efficiently.

This machine is widely used for:

- Cutting scrap steel and iron into smaller sizes

- Processing steel plates, beams, and pipes

- Preparing materials for metal recycling furnaces

- Reducing oversized scrap for easier storage and transport

What Materials Can a Gantry Shear Process?

A gantry shear is suitable for cold shearing a wide variety of scrap and metal materials, including light and thin steel sections, rebar, steel plates, nickel plates, round steel, steel pipes, stainless steel, scrap copper, scrap steel, scrap iron, aluminum alloys, copper materials, metal bales, car bodies, light metal structures, steel wires, and iron filings. It can cut large-sized metal raw materials into furnace-ready or recycling-ready sizes, making them easier to store, transport, and process further.

Thanks to its versatility, a gantry shear for scrap metal can serve as a primary processing machine in scrap yards and recycling plants, as well as in foundry workshops for furnace charge preparation. It is also widely used in mechanical manufacturing and construction industries for cutting metal materials.

Benefits for Scrap Metal Recycling Businesses

- Increased Processing Efficiency – Cuts large scrap into furnace-ready sizes, reducing manual cutting time.

- Improved Scrap Value – Properly sized scrap is easier to transport and fetches a higher market price.

- Lower Labor Costs – Automated cutting reduces the need for multiple workers.

- Safe and Reliable – Hydraulic shearing minimizes sparks and reduces risks compared to flame cutting.

Structure of the Gantry Shear

Scrap Box

The scrap box is used to store various types of metal scrap and serves as the working platform during the cutting process. It is often loaded with the help of a loader, which makes feeding the materials fast and efficient.

Machine Head

The machine head is a vertical frame structure and the core part of the hydraulic gantry shear. It is equipped with a hydraulic cylinder at the top, which presses down on the scrap during operation to ensure stability and precision in cutting.

Blades

The blades are the key components for cutting metal scrap. Different models of gantry shear for scrap metal are equipped with blades of different sizes and materials to meet diverse cutting needs. Since blades are wearing parts, it is recommended to keep several spare sets to ensure continuous production.

Working Principle of the Gantry Shear for Scrap Metal

- Feeding: Use a loader to feed metal scrap into the scrap box.

- Closing the Door: When the scrap reaches a certain amount, stop feeding and close the chamber door.

- Hydraulic Pushing: The hydraulic cylinder at the back of the scrap box pushes the metal scrap forward toward the machine head.

- Pressing the Material: The hydraulic cylinder at the top of the machine head presses the scrap tightly into position.

- Blade Cutting: The cutting blade moves downward, shearing the scrap quickly and effectively.

- Cycle Operation: After cutting, the machine resets to its initial position and repeats the process.

How to Choose the Right Gantry Shear For Scrap Metal

When buying a hydraulic gantry shear, consider:

- Cutting force and blade size based on the thickness of your scrap

- Machine capacity to match your daily processing volume

- Hydraulic system quality for long-term stability

- After-sales support for maintenance and spare parts availability

Shuliy Machinery can recommend the most suitable gantry shear model based on the customer’s specific needs, such as the type and size of metals to be processed, daily output targets, finished product specifications, plant layout, and budget.

We also offer customization services, including shear opening size, blade material, and hydraulic system configuration, to ensure the equipment achieves the optimal balance between performance and cost.

Applications in the Metal Recycling Industry

A gantry shear for scrap metal is an essential machine in:

- Scrap yards for cutting heavy steel

- Metal recycling plants for preparing furnace-ready scrap

- Steel mills for reprocessing off-cuts and defective steel

- Demolition projects for reducing large steel structures

Related Metal Recycling Machines

In addition to gantry shear for metal scrap cuttings, we also provide other types of metal recycling machines to meet different processing needs:

- Metal Balers: Designed to compress various scrap metals such as steel, aluminum, and copper into compact bales for easier storage, handling, and transportation.

- Metal Shredders: Used for shredding large pieces of metal waste into smaller, uniform sizes, making them more suitable for recycling and smelting.

Hydraulic Gantry Shear For Sale

The gantry shear for scrap metal is a vital piece of equipment for any scrap processing or metal recycling operation that handles large, heavy, and bulky metal materials. With its powerful hydraulic cutting system, sturdy frame, and wide application range, it can greatly improve productivity, reduce operational costs, and help you maximize scrap value.

If you are looking for a reliable hydraulic gantry shear machine for your recycling yard or steel processing facility, contact us today for a customized solution and quotation. Our team will help you select the right model based on your scrap type, cutting size, and production needs.