Pabrik Daur Ulang Botol PET

Pabrik daur ulang botol PET adalah peralatan khusus untuk mendaur ulang dan mengolah limbah botol PET menjadi serpihan botol. Artikel ini adalah pengenalan rinci tentang jalur pencucian botol PET. Artikel ini adalah pengenalan rinci tentang jalur pencucian botol PET, termasuk konfigurasi, proses daur ulang, parameter, kasus, dan sebagainya.

Pabrik daur ulang botol PET adalah peralatan khusus untuk mendaur ulang dan mengolah limbah botol PET menjadi serpihan botol. Melalui jalur ini, kami dapat secara efisien mengubah limbah botol PET menjadi serpihan botol berkualitas tinggi untuk produksi ulang botol PET atau produk terkait lainnya.

Lini pencucian botol PET kami memiliki kapasitas produksi yang sangat baik yaitu 500kg hingga 6000kg per jam, dan kami dapat menyesuaikan konfigurasi dan kapasitas peralatan lini tersebut sesuai dengan kebutuhan pelanggan. Sebagai produsen mesin daur ulang botol PET, kami tidak hanya menyediakan peralatan lengkap tetapi juga mencakup dukungan teknis dan layanan purna jual untuk memastikan bahwa pelanggan kami didukung dan dilindungi sepenuhnya selama proses daur ulang.

Video 3D Proses Daur Ulang Botol PET

Video ini menunjukkan proses daur ulang jalur pencucian botol PET dengan kapasitas 1000kg per jam. Selain itu, kami menawarkan solusi untuk kapasitas yang lebih besar, seperti jalur yang memproses 3000kg per jam.

Keuntungan Pabrik Daur Ulang Botol Plastik

- Fleksibilitas konfigurasi tinggi untuk memaksimalkan sumber daya ruang dan peralatan.

- Kapasitas produksi tinggi untuk memenuhi kebutuhan berbagai skala produksi.

- Melalui proses pencucian dan pemisahan multi-tahap, pabrik daur ulang botol PET dapat berproduksi serpihan botol PET dengan kemurnian tinggi dengan nilai pasar tinggi.

- Menyediakan solusi yang dibuat khusus untuk memastikan hasil pembersihan optimal dan efisiensi ekonomi.

Pengenalan Pabrik Daur Ulang Botol PET

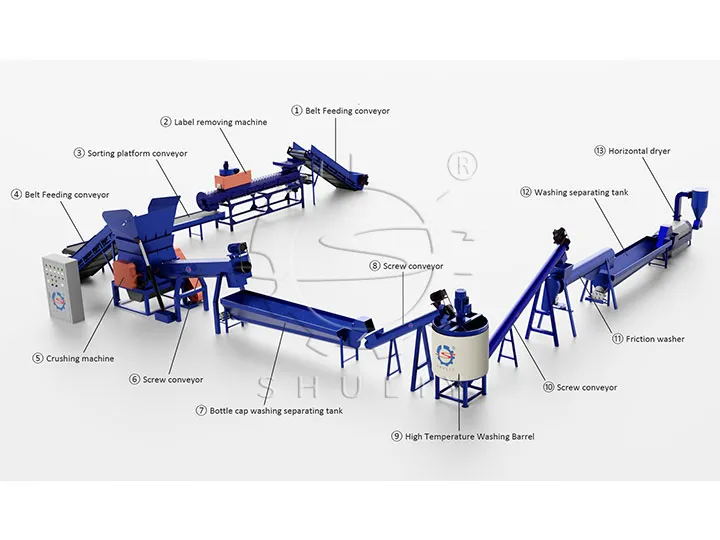

Mesin pencuci botol PET adalah solusi lengkap untuk daur ulang botol PET, termasuk mesin penghapus label botol PET, penghancur botol PET, tangki pemisah pelampung wastafel, mesin cuci panas serpihan PET, mesin cuci gesekan PET, dan mesin pengering serpihan PET. Lini produksi tidak hanya dapat mendaur ulang botol PET biasa seperti botol air mineral, botol bir, dan botol minuman, tetapi juga memproses semua jenis wadah PET, seperti botol kemasan makanan dan botol produk pembersih.

Pabrik Pencucian Botol PET yang disesuaikan

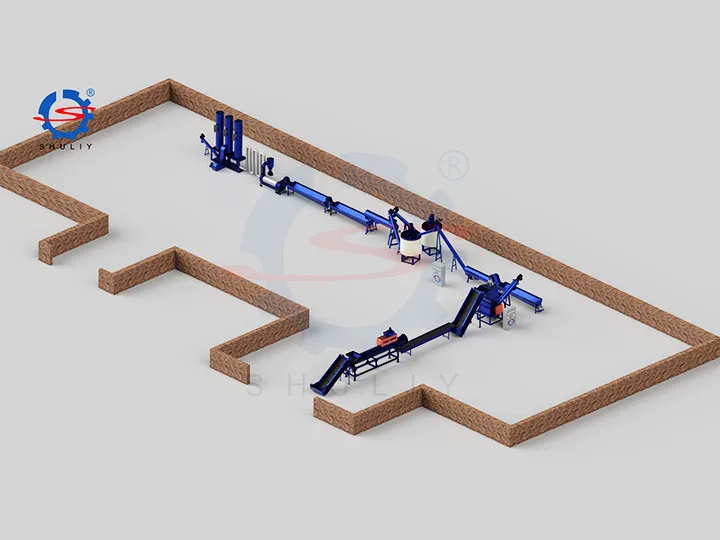

Kami berkomitmen untuk menyediakan solusi pabrik daur ulang botol PET yang disesuaikan, kami tidak hanya dapat menyesuaikan konfigurasi, keluaran, dan tampilan jalur daur ulang sesuai dengan kebutuhan pelanggan, namun kami juga dapat merancang rencana penempatan jalur pencucian botol PET yang sesuai sesuai dengan ukuran dan kebutuhan tata letak pabrik pelanggan.

Terlepas dari ukuran pabrik pelanggan, kami dapat menyesuaikan tata letak optimal pabrik daur ulang botol PET untuk memanfaatkan ruang sepenuhnya untuk memastikan pengoperasian peralatan yang efisien, dan memaksimalkan efisiensi produksi. Melalui solusi penempatan yang dirancang dengan baik, kami tidak hanya dapat memaksimalkan efisiensi produksi, namun juga mengoptimalkan alur kerja, meningkatkan pemanfaatan peralatan, dan memberikan kenyamanan dan manfaat yang lebih besar bagi operasi produksi pelanggan kami.

Bahan Baku Dan Produk Akhir

Pabrik daur ulang botol PET mampu mengolah botol PET bekas seperti botol cola, botol minuman, botol air mineral, dll, dan mengolahnya menjadi serpihan botol berkualitas tinggi yang dapat digunakan kembali untuk memproduksi botol PET atau produk terkait lainnya. Melalui teknologi pemrosesan yang canggih, kami memastikan kualitas serpihan botol yang dihasilkan stabil dan memenuhi standar dan persyaratan terkait. Berikut ini adalah standar serpihan PET yang diproduksi oleh jalur daur ulang ini.

- Kadar air: <0,5-1%

- pH: <8,0

- Konten PVC: <100ppm

- Konten PE/PP: <200ppm

- Konten pengotor: ≤300-500mg/kg

- Kandungan bubuk: ≤ 2000-3000mg/kg

- Ukuran partikel: <16-18mm

Alur Kerja Pabrik Pencucian Botol PET

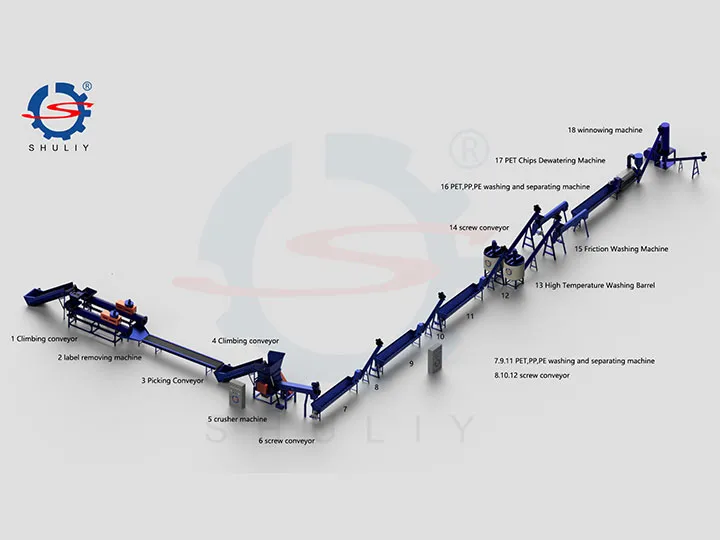

Proses daur ulang botol PET mencakup langkah-langkah seperti penghilangan label, penghancuran, pemisahan mengapung dan tenggelam, pencucian panas, pencucian gesekan, dan pengeringan. Setiap langkah dirancang dan disesuaikan dengan hati-hati untuk memastikan hasil daur ulang yang optimal dan produktivitas. Dari botol PET bekas menjadi serpihan yang dapat digunakan, seluruh proses ini efisien dan ramah lingkungan.

Prosesnya dapat dioptimalkan dan disesuaikan dengan kebutuhan aktual atau volume produksi. Misalnya, dua tangki pencucian panas dapat digunakan saat memproses volume yang lebih besar dan dua langkah pembilasan dapat ditambahkan setelah tangki pencucian panas untuk memastikan pembersihan yang efektif.

Mesin Daur Ulang Botol PET Utama

Mesin penghilang label botol PET: Mesin ini dirancang khusus untuk menghilangkan label dari botol PET. Dilengkapi dengan beberapa bilah karbida, mesin ini secara efisien menghilangkan label dengan cara memutar dan memotong. Botol bulat dapat mencapai tingkat penghilangan label 98%-99%, sedangkan botol datar biasanya mencapai 85%-90%.

Penghancur botol PET: Mesin ini dirancang khusus untuk menghancurkan botol PET menjadi serpihan untuk pencucian selanjutnya. Material bilah penghancur ini adalah 9Crsi dan ukuran layar adalah 16-18mm.

Tangki pemisahan tenggelam mengapung: Mesin ini memisahkan serpihan botol PET dari tutup PP, PE, atau label PVC. PET tenggelam karena densitasnya yang lebih tinggi, sedangkan PP dan PE mengapung. Konveyor sekrup di bagian bawah mesin pembersih menggerakkan serpihan PET ke depan.

Mesin pencucian panas serpihan PET: Mesin ini secara efektif membersihkan dan mendekontaminasi serpihan botol menggunakan air panas dan deterjen, biasanya pada suhu 85°C hingga 95°C. Mesin ini juga dapat digunakan untuk membersihkan dan mendekontaminasi botol dan serpihan.

Mesin pencuci gesekan PET: Fungsi mesin ini adalah untuk mengenakan serpihan PET pada gesekan dan air dalam drum atau ruang berputar. Ini membantu menghilangkan kontaminan yang membandel dari permukaan serpihan botol. Mesin pencuci gesekan ini biasanya ditempatkan pada sudut 45 derajat untuk drainase yang lebih baik.

Mesin pengering serpihan PET: Mesin ini menggunakan gaya sentrifugal untuk secara efektif menghilangkan air dari serpihan botol PET, yang dapat mengontrol air kurang dari 3%-5%, ditambah pipa pengering untuk mengontrol air kurang dari 0.5%-1%.

Spesifikasi Pabrik Daur Ulang Botol PET

| Kapasitas | 500kg/jam-6000kg/jam |

| Bahan mentah | Botol PET berbagai ukuran |

| Produk akhir | Serpihan PET daur ulang |

| Aplikasi serpihan botol PET | Granulasi, produksi serat, cetakan tiup, cetakan injeksi |

| Aksesori wajib | Pisau penghancur, saringan, penggiling, bubuk pembersih |

| Peralatan opsional | Tabung pengering, pemisah udara |

| Kemampuan penyesuaian | Dapat disesuaikan |

| Metode instalasi | Panduan online atau bantuan di tempat |

Tip Jalur Pencucian Botol PET

- Pemisahan de-labeling: Botol pipih dan botol bundar harus dihilangkan labelnya secara terpisah karena pisau yang digunakan berbeda.

- Menghancurkan air: saat menghancurkan perlu menggunakan banyak air untuk membilas sedimen, untuk mencegah kontaminasi pada pembersihan selanjutnya.

- Perawatan pisau: Rautan menjaga pisau tetap tajam dan perawatan rutin memperpanjang umur peralatan.

- Opsi tangki air dalam: Jika potongan botolnya tipis, penggunaan tangki air yang dalam akan membantu potongan botol tersebut tenggelam.

- Pencucian panas: Panci cuci air panas dengan bubuk pembersih atau alkali untuk menghilangkan noda membandel secara efektif.

- Kontrol kelembaban: tambahkan pipa pengering setelah pengering untuk mengontrol kelembapan pada 0.5%-1%.

- Pemisahan angin: Pemisah angin memisahkan label halus dan debu untuk meningkatkan kemurnian serpihan botol.

- Dukungan pengeringan: pipa pengering perlu dipasang sebelum pemisah udara untuk memastikan bahan kering.

Video Kerja Pabrik Daur Ulang Botol PET

Mesin Daur Ulang Botol Plastik Dijual

Proyek Daur Ulang Botol PET Di Sudan Selatan

Pelanggan di Sudan Selatan ini memproduksi air murni dalam kemasan dan bir serta telah mengumpulkan sejumlah besar limbah dan botol kadaluwarsa. Pelanggan ingin mengolah botol-botol ini menjadi pelet PET untuk ditiup ulang. Kami menyesuaikan solusi untuk pelanggan dan mengirim teknisi ke pabrik pelanggan untuk membantu pemasangan.

Detail lebih lanjut dapat dilihat: Mesin Daur Ulang Plastik PET Dipasang Di Sudan Selatan Untuk Memproduksi Resin Daur Ulang

Mesin Pembuat Serpihan PET 500kg/jam Diekspor Ke Nigeria

Di bawah ini adalah mesin pembuat serpihan PET yang disesuaikan untuk pelanggan di Nigeria, dengan produksi 500kg/jam. Serpihan PET akhir berukuran 10-12 mm dan digunakan untuk membuat serat stapel.

Detail lebih lanjut dapat dilihat: Proyek Daur Ulang Di Nigeria: Pengiriman Mesin Daur Ulang PET 500KG/JAM

Harga Mesin Daur Ulang Botol PET

Sebagai produsen mesin daur ulang botol PET, kami sangat menyadari kekhawatiran pelanggan kami mengenai harga pabrik daur ulang botol PET. Kami menawarkan berbagai macam model dan konfigurasi mesin daur ulang botol PET, dengan harga yang bervariasi berdasarkan faktor seperti spesifikasi peralatan, kapasitas, dan fitur.

Kami berkomitmen untuk menawarkan harga yang kompetitif dan memastikan bahwa kinerja dan kualitas peralatan dapat memenuhi kebutuhan pelanggan kami. Kami juga menawarkan opsi pembayaran yang fleksibel dan layanan purna jual yang dipersonalisasi untuk memastikan pelanggan kami menerima pengalaman dan dukungan terbaik selama pembelian dan penggunaan. Selamat datang untuk menghubungi kami untuk informasi lebih lanjut tentang harga dan detail mesin daur ulang plastik PET.