Faktor-Faktor Yang Mempengaruhi Kualitas Pelet Granulator Plastik

Granulator plastik adalah peralatan penting yang menghasilkan pelet plastik dengan cara dipanaskan, dilebur, diekstrusi, didinginkan,…

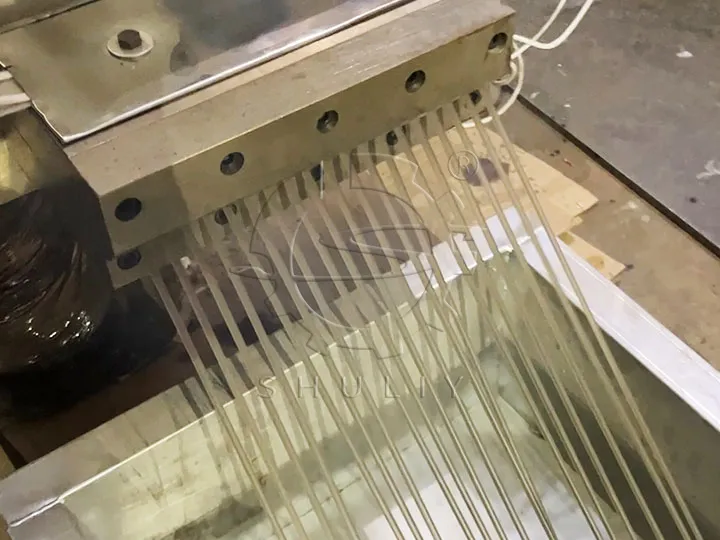

Granulator plastik merupakan peralatan penting yang memproduksi pelet plastik dengan cara memanaskan, melelehkan, mengekstrusi, mendinginkan, dan memotong limbah plastik atau bahan baku plastik. Kualitas butiran plastik secara langsung mempengaruhi kinerja dan masa pakai produk hilir.

Oleh karena itu, memahami dan mengendalikan faktor-faktor yang mempengaruhi kualitas pelet mesin daur ulang pelet plastik penting untuk meningkatkan kualitas produk plastik secara keseluruhan. Pada artikel ini, kita akan membahas beberapa faktor kunci untuk membantu perusahaan mengontrol kualitas produk dengan lebih baik dalam proses produksi.

Seleksi Dan Pretreatment Bahan Baku

Kemurnian Bahan Baku

Bahan baku plastik dengan kemurnian tinggi dapat mengurangi pengaruh pengotor terhadap kualitas pelet dan menghindari masalah kualitas seperti flek hitam dan bintik pada pelet. Oleh karena itu, dalam memilih bahan baku sebaiknya usahakan memilih plastik dengan kemurnian tinggi.

Pengeringan Bahan Baku

Kelembaban pada bahan baku plastik akan diubah menjadi gelembung udara selama proses ekstrusi suhu tinggi, sehingga mempengaruhi kepadatan dan kualitas permukaan pelet. Oleh karena itu, sebelum pembuatan pelet, bahan mentah harus dikeringkan sepenuhnya untuk memastikan kadar airnya memenuhi persyaratan proses.

Kinerja Granulator Plastik

Sistem Kontrol Suhu

Sistem pengatur suhu granulator plastik secara langsung mempengaruhi keadaan leleh dan fluiditas plastik. Suhu yang terlalu tinggi atau terlalu rendah akan mempengaruhi efek plastisisasi plastik yang selanjutnya mempengaruhi kualitas pelet. Oleh karena itu, sistem kontrol suhu yang stabil dan akurat sangat penting untuk menjamin kualitas pelet.

Desain dan Keausan Sekrup

Sekrup adalah komponen inti granulator plastik, dan desain serta keausannya secara langsung mempengaruhi efek ekstrusi plastik. Desain sekrup yang wajar dan keausan yang rendah dapat memastikan plastisisasi yang seragam dan ekstrusi plastik yang stabil, sehingga meningkatkan keseragaman dan konsistensi pelet.

Optimalisasi Parameter Proses

Kecepatan Ekstrusi

Ekstrusi yang terlalu cepat dapat menyebabkan plastik tidak sepenuhnya terplastikasi, sementara terlalu lambat dapat menyebabkan plastik tetap berada di sekrup terlalu lama dan mengalami degradasi. Oleh karena itu, perlu untuk menyesuaikan kecepatan ekstrusi granulator plastik secara wajar sesuai dengan karakteristik bahan baku plastik yang berbeda untuk memastikan kualitas pelet.

Kecepatan dan Mode Pendinginan

Pendinginan merupakan langkah penting dalam pencetakan pelet plastik. Pendinginan yang terlalu cepat atau terlalu lambat akan mempengaruhi kristalinitas dan stabilitas dimensi pelet. Penggunaan metode dan kecepatan pendinginan yang tepat dapat meningkatkan kualitas tampilan dan sifat fisik pelet.

Ada berbagai faktor yang mempengaruhi kualitas pelet granulator plastik, antara lain pemilihan dan perlakuan awal bahan baku, kinerja peralatan, dan optimalisasi parameter proses. Dengan mempertimbangkan secara komprehensif dan mengendalikan faktor-faktor ini secara wajar, perusahaan dapat secara efektif meningkatkan kualitas butiran plastik, sehingga meningkatkan kinerja dan daya saing pasar produk hilir.