パラフィンワックスパストリオーター

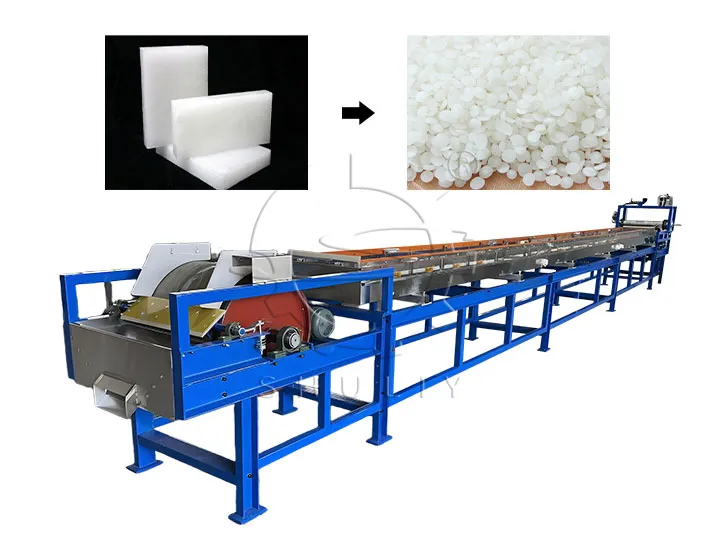

パラフィンワックスペースライターは、溶融したパラフィンワックスを連続的に冷却し、…に形成する工業用機械です。

パラフィンワックスペースライターは、溶融したパラフィンワックスを連続的に冷却し、均一な粒状に形成する工業用機械です。パラフィンワックス粒子、香りビーズ、鋳造用ワックス、脱毛ワックスなどの製品の生産に広く使用されています。

ワックスペースライター装置の概要

パラフィンワックスペースライターは、ワックスペースライターまたはパラフィンペレット化機とも呼ばれ、主に溶融したパラフィンを制御された冷却条件下で規則的な形状の固体粒子に変換するために使用されます。

この機械は連続生産設計を採用しており、安定した動作と一貫した製品形状を保証します。完成した粒子は取り扱いやすく、保管や輸送も容易であり、ほとんどの工業および商業用途の要件を満たします。

原材料と完成品

適用原材料

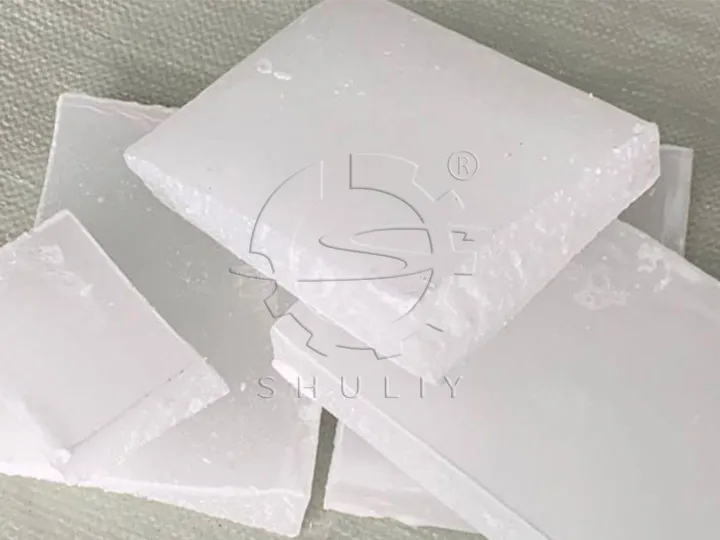

このパラフィンワックスペースライターは、加熱によって溶かし、冷却後に再び固化できるすべての材料に適しています。材料の融点が50〜250°Cの範囲内であれば、このワックス粒化ラインで処理可能です。

一般的に適用可能な原材料には:

- パラフィンワックス

- ロジンおよびロジン系樹脂

- その他の樹脂タイプの溶解可能な材料

- さまざまな工業用ワックス

溶解・混合段階では、顧客の要件に応じて色素や機能性添加剤を追加できます。材料は十分に混合されてから粒化され、着色やカスタマイズされたワックス粒子の生産が可能です。

完成品

パラフィンワックス機械による粒化後、完成品は均一な形状とサイズになり、さまざまな下流用途に適しています。代表的な完成品には:

- パラフィンワックス粒子

- 香りビーズ

- 鋳造用ワックス粒子

- 脱毛ワックス粒子

- その他の工業用ワックスまたは樹脂粒子

最終製品は通常半球形で、粒子サイズは工程要件に応じて調整可能であり、包装、保管、輸送、さらなる処理に便利です。

パラフィンワックス生産ラインの構成

完全なパラフィンワックスペースライターシステムは、通常、以下から構成される生産ラインとして供給されます。

- 混合および溶解タンク原材料の加熱、溶解、混合に使用される。色をこの段階で追加可能です。

- 材料ポンプ溶融材料を安定して供給します

- 熱油ヒーターパイプラインの温度を維持し、材料の固化を防止します

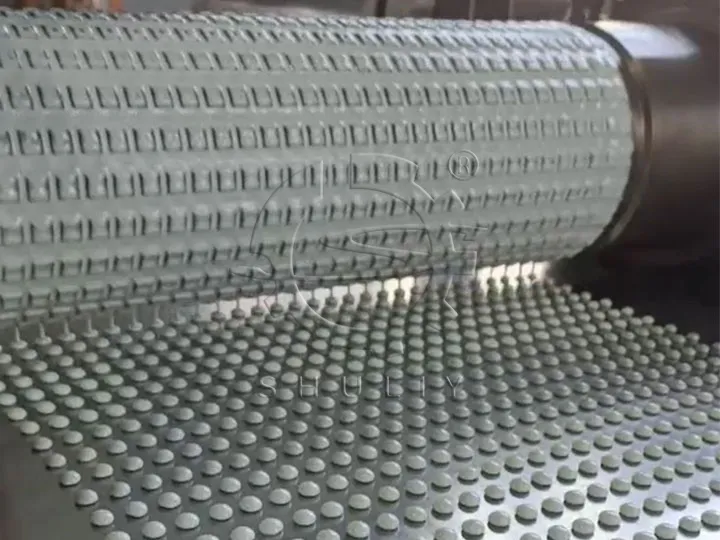

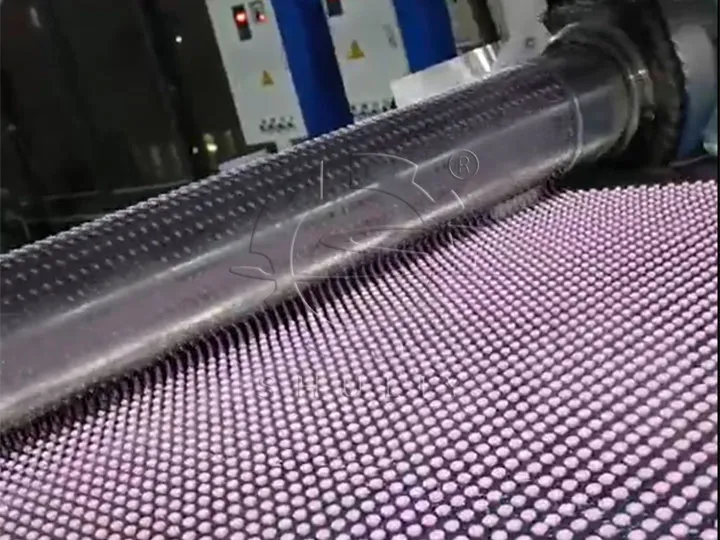

- ペースライター(粒化機)溶融材料を均一な粒子に形成します

- 水ポンプと水タンク新たに形成された粒子を水噴霧で冷却します

- チラー冷却水を安定した温度に保ち、循環させる

このワックス粒化ラインは、明確な構造とシンプルな操作ロジックを特徴とし、連続工業生産に適しています。

ワックス粒化ラインの動作原理

原材料は加熱され、完全に溶解された後、絶縁パイプラインを通じてパラフィンワックスペースライターに輸送されます。

ペースライターは、溶融した材料を均一に落下させ、水噴霧によって急速に冷却・固化し、均一な粒子を形成します。

冷却水はチラーを通じてリサイクルでき、エネルギー消費を削減し、全体的な生産効率を向上させます。

粒子サイズと容量の調整

- 粒子サイズ:通常4〜8 mmで、供給速度と粒化ヘッドの高さを制御して調整可能です。

- 金型穴のサイズ:通常1.8〜2.2 mm

- 粒子形状:半球形

異なる機械モデルは異なる容量を提供します。パラフィンワックスの場合、一般的な出力範囲は50 kg/hから600 kg/hまでで、選択したモデルと材料の特性によります。

冷却方法と動作条件

パラフィンワックスペースライターは、一般的に水冷システムを採用し、粒子を冷却・固化します。

容量が高いプロジェクトやより厳しい冷却要件がある場合は、チラーを装備して水温を一定に保ち、生産の安定性と出力効率を向上させることができます。

電圧、モーターの構成、タンク容量は、現地の電力規格や顧客の現場条件に応じてカスタマイズ可能です。

このパラフィンワックス粒化ソリューションの利点

- 連続かつ安定した生産に適しています

- 均一な粒子形状と一貫した品質

- さまざまな溶解可能な材料に対応

- 柔軟な生産ライン構成

- 異なる製品要件に対応できるように色のカスタマイズをサポートします

詳細についてはお問い合わせください

パラフィンワックスペースライターは、安定した製品品質、安定した出力、柔軟な適用オプションを必要とする顧客にとって信頼性の高い実証済みのソリューションです。

原料の特性、目標容量、用途のニーズに基づき、適切な機械モデルと完全な生産ラインソリューションを提供できます。

パラフィンワックス粒化機または完全なパラフィンワックス生産ラインをお探しの場合は、詳細な仕様、技術サポート、価格情報についてお気軽にお問い合わせください。