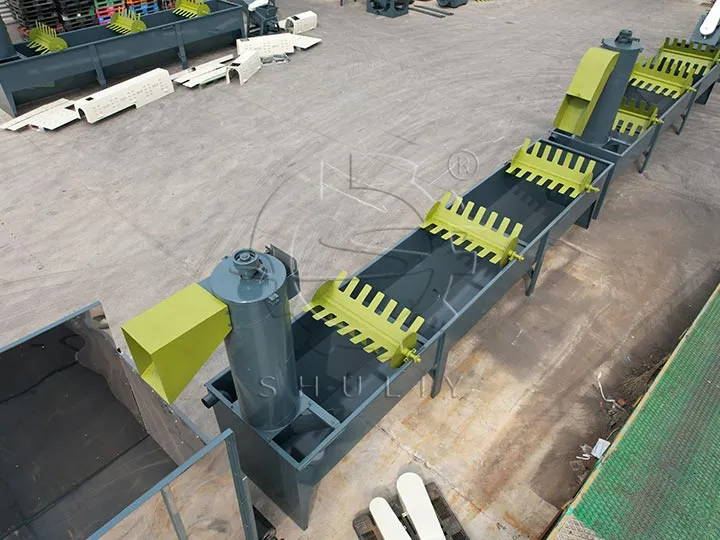

Plastic Film Dryer Machine

The plastic film dryer machine, also known as a vertical dewatering machine, is specialized equipment for processing plastic bags, woven bags, and other film plastics. Its main function is to lift the plastic film out of the plastic washing tank and dry it.

The plastic film dryer machine, also known as a vertical dewatering machine, is specialized equipment for processing plastic bags, woven bags, and other film plastics. Its main function is to lift the plastic film out of the plastic washing tank and dry it. This equipment is widely used in plastic film recycling lines and is designed to ensure that the recycled plastic material is properly dried for subsequent processing and reuse.

Application Video Of Vertical Dewatering Machine

Working Principle Of Plastic Film Dewatering Machine

Plastic film dewatering machine, also known as vertical dewatering machines, mainly adopts high-speed extraction centrifugal dewatering and upright conveying type working principle.

- High-speed extraction centrifugal dewatering: After entering the plastic film dryer machine, the plastic film is placed inside a rotating cylinder. The high-speed rotation inside the cylinder generates a centrifugal force that quickly throws off the moisture in the film.

- Upright conveyor work: While centrifugal dewatering, the plastic film pieces are conveyed upright to the top of the dryer and then on to the next process.

Why Use The Plastic Film Dryer Machine?

There are several main reasons why plastic film needs to be dehydrated and dried before it enters the plastic recycling granulator for pelletizing:

- Avoiding thermal decomposition: The moisture in plastic film is easy to be thermally decomposed under high temperatures, which affects the quality of plastic and pelletizing. Dehydration drying can reduce the moisture content, reduce the adverse reaction, and ensure the stability of the granulation process and good product quality.

- Improve pelletizing efficiency: Plastic film containing water may affect the material flow and processing performance during the pelletizing process, reducing the pelletizing efficiency. Through dehydration and drying, it can reduce the humidity of plastic film, reduce the adhesion and blockage phenomenon in the granulator, and improve the production efficiency and yield of granulation.

- Ensure product quality: In the process of pelletizing, the moisture in the plastic film may cause the surface of the pellets to be not smooth, bubbles, and other defects, affecting the quality of the final product. Through dehydration drying, it can make the surface of plastic film smooth and even, reduce bubbles and defects in granules, and ensure that the quality of the final product meets the requirements.

Vertical Dewatering Machine Parameters

Our popular models are SL-500 and SL-600, with power of 7.7kw and 15kw respectively. Besides these two models, we also provide many different specifications of plastic film dryer machines to meet the production needs and process requirements of different customers.

Related Plastic Film Recycling Machine

The plastic film dryer machine is strategically positioned at the end of the plastic washing tank, serving to efficiently dry and elevate the plastic fragments from the cleaning basin. Working in tandem with the plastic bag shredder and plastic recycling granulator machine, these machines form an integral part of the plastic film granulation line.