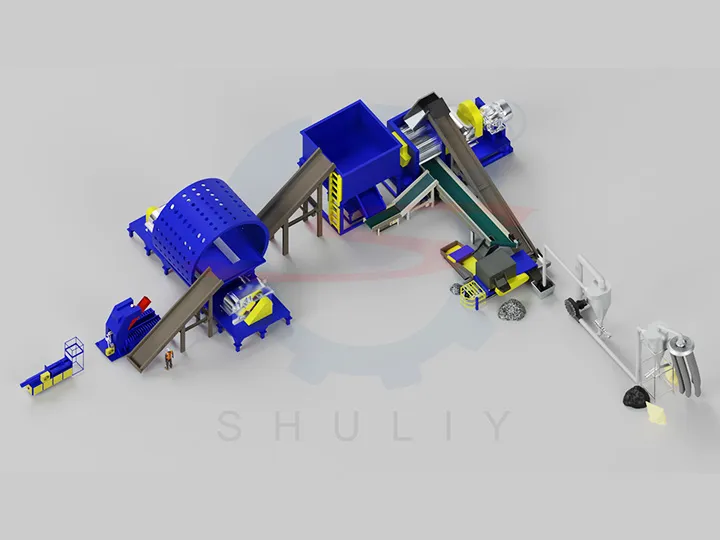

Полностью автоматическая линия по переработке отработанных шин

С учетом растущего спроса на переработку废轮дов, полностью автоматическая линия по переработке废轮дов, как важный…

С учетом растущего спроса на переработку отработанных шин, полностью автоматизированная линия по переработке отработанных шин, как важное оборудование для эффективной переработки отработанных шин, привлекает все больше внимания со стороны предприятий по переработке шин. В качестве профессионального производителя машин для переработки шин мы предоставляем зрелые и надежные решения для автоматизированных линий по производству резинового порошка, чтобы удовлетворить потребности различных клиентов в объеме, тонкости частиц и степени автоматизации.

Сырьё и готовая продукция

- Сырьё: Отработанные шины (≤1200 мм в диаметре), включая шины с металлическим кордом и без него

- Конечные продукты: Резиновые гранулы (1–5 мм); резиновый порошок (10–40 сетка)

- Восстановление побочных продуктов: Отделённые стальные провода и нейлоновые волокна могут быть собраны и повторно использованы

Множественные решения по предварительной обработке

Чтобы удовлетворить различные условия на месте и типы шин, мы предлагаем три полностью автоматические линии по переработке отработанных шин. Все решения включают автоматические системы транспортировки и хранения, чтобы обеспечить непрерывный и стабильный процесс измельчения.

Решение 1

- Машина для удаления корда: Извлекает стальные провода из боковин шин

- Машина для резки шин: Режет шины на секции для облегчения измельчения

- Шредер для шин: Разбивает сегменты шин на резиновые блоки

- Промежуточный конвейер: Переносит материалы в автоматическую систему хранения

- Автоматический конвейер для хранения и выгрузки: Обеспечивает непрерывную подачу в резиновую мельницу

- Резиновая мельница: Измельчает резиновые блоки в гранулы 1–5 мм или порошок 10–40 сетка

- Сепаратор волокон: Удаляет нейлоновое волокно из резинового материала

- Система сбора резинового порошка: Сбор готового порошка для упаковки или хранения

Решение 2

- Машина для разделения и резки стального провода шин: Отрезает обод и сегментирует шину

- Машина для удаления проволоки из шин: Отделяет стальную проволоку от резины в области обода

- Шредер для шин: То же самое, что и выше

- Система транспортировки и хранения: То же самое, что и выше

- Дробилка резины, сепаратор волокна, система сбора: То же самое, что и выше

Решение 3

Для клиентов с предварительно нарезанными секциями шин

- Машина для измельчения шин: Непосредственно обрабатывает предварительно нарезанные блоки шин

- Система транспортировки и хранения: То же самое, что и выше

- Машина для получения резинового порошка, сепаратор волокна, система сбора: То же самое, что и выше

Рабочее видео линии переработки отработанных шин

Выход линии по переработке отработанных шин

Мы предлагаем линии по производству резинового порошка с различными вариантами мощности, от 80 кг/ч до 2300 кг/ч, подходящие для проектов по переработке шин разных масштабов. Также доступны модели на заказ для более высоких требований к мощности. Типичный размер резинового порошка составляет 10–40 меш, а фактическая производительность тесно связана с конечным размером частиц — чем крупнее частицы, тем выше производительность; чем мельче частицы, тем ниже производительность.

Почему стоит выбрать нашу машину для переработки шин?

Выбор подходящего комплекта оборудования для переработки шин имеет решающее значение для повышения эффективности переработки и контроля производственных затрат. Вот несколько ключевых преимуществ нашей линии переработки废轮胎:

- Зрелый опыт технологий: Годы сосредоточенности на оборудовании для переработки шин, предоставление стабильных и надежных решений.

- Высокая автоматизация: Достигает полной автоматизации процесса от дробления до сортировки и разделения, снижая затраты на труд.

- Гибкая конфигурация: Предлагает различные комбинации предварительной обработки для удовлетворения различных типов шин и требований к мощности.

- Легкость в эксплуатации и обслуживании: Простая и понятная структура оборудования, что облегчает ежедневное использование и обслуживание.

- Гарантия обслуживанияПредоставляет руководство по установке, обучение по эксплуатации и поставку запасных частей, обеспечивая беспечную послепродажную поддержку.

Если вы ищете стабильное, эффективное и применимое решение для переработки шин, пожалуйста, свяжитесь с нами для получения более подробной информации.