Машина для прессования металлического лома

Наша машина для брикетирования металлического лома специально разработана для сжатия стального лома, алюминиевых стружек, медных листов и других...

Наша машина для прессования металлического лома специально разработана для сжатия стального лома, алюминиевых стружек, медных листов и других металлических материалов. Она преобразует свободные металлические отходы в компактные блоки или цилиндрические тюки, значительно уменьшая объем, увеличивая эффективность загрузки и облегчая подачу в печь. Широко используется в центрах переработки, металлургических заводах и плавильных предприятиях, машина поддерживает индивидуальные размеры тюков и уровни автоматизации, что делает ее идеальным решением для повышения эффективности утилизации и прибыльности.

Мы являемся ведущим производителем гидравлических прессов для металлолома. Будь то маленькая стальная утварь или большой громоздкий автомобиль, наши гидравлические прессы могут справиться с любым размером металлического лома. Мы используем высококачественные материалы для производства наших прессов, которые являются прочными и надежными.

Подходит для широкого спектра металлов

Наш металлопресс подходит для сжатия широкого спектра черных и цветных металлов, включая:

- Металлолом стали, металлолом железа, обрезки от штамповки и старые кузова автомобилей

- Отходы алюминия, алюминиевые стружки, медные листы, медный лом и обрезки нержавеющей стали

- Металлические стружки, железная пыль, алюминиевые банки, металлические бочки и многое другое

Сжатые тюки могут быть сформированы в прямоугольные блоки, цилиндрические формы или плоские плиты в соответствии с требованиями заказчика. Готовые тюки имеют однородный размер и высокую плотность, что облегчает их хранение, транспортировку и подачу в печи для дальнейшей переработки.

Почему стоит выбрать металлопрессы?

Прессование значительно уменьшает объем металлического лома, экономя место для хранения, улучшая эффективность загрузки и снижая транспортные расходы. Более того, компактные металлические блоки легче загружать в печи на сталелитейных заводах или металлургических заводах, что повышает как ценность переработки, так и эффективность обработки. Для клиентов с высоким объемом ежедневной переработки инвестиции в эффективную машину для прессования металлического лома могут значительно повысить общую продуктивность.

Особенности нашего пресса для металлического лома

Мы предлагаем машины для прессования металла в различных конструктивных исполнениях, включая вертикальные и горизонтальные конфигурации. Основная рама изготовлена из утолщенных стальных плит и усиленных конструктивных поддержек, чтобы обеспечить отличную стабильность и долговечность даже при высоконапорной эксплуатации.

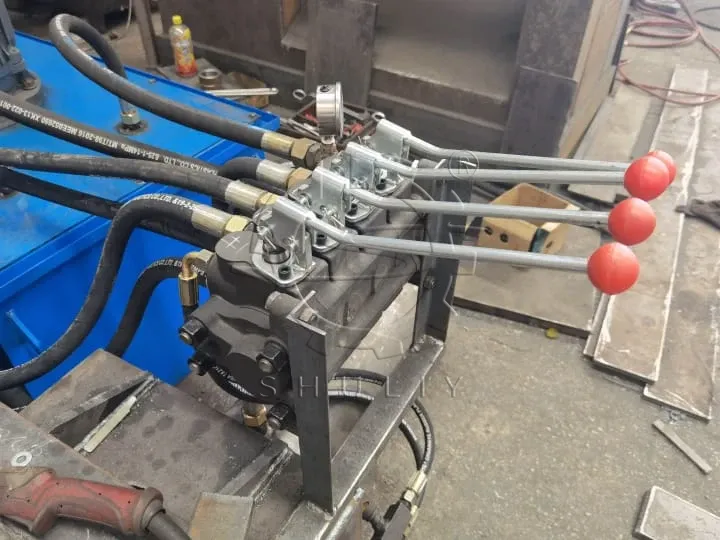

- Гидравлическая система: Оснащена высокоэффективными гидравлическими цилиндрами, которые приводят в действие компрессионную головку для плавного и надежного формирования металлических тюков.

- Система управления: Доступна в ручном режиме или полностью автоматическом управлении PLC, обеспечивая простоту и удобство в эксплуатации.

- Методы выгрузки тюков: Поддерживает боковую поворотную, боковую толкающую, фронтальную толкающую или безвыгрузочные опции для различных предпочтений в работе.

- Индивидуальная настройка формы: Компрессионная головка и форма могут быть настроены для производства различных форм и размеров тюков по мере необходимости.

- Ассортимент продукции и модели: Мы предлагаем широкий выбор моделей прессов для металлолома с различными характеристиками и мощностями, чтобы удовлетворить разнообразные потребности клиентов различного масштаба.

Принцип работы пресса для металлического лома

Металлолом подается в камеру сжатия через загрузочный вход. Затем гидравлическая система приводит в действие пресс-головку, чтобы приложить силу и сжать металл. Как только достигается заданное давление, материал формируется в компактный тюк. После формирования тюк выгружается либо путем толкания, либо наклона, завершая один рабочий цикл.

Вся машина для прессования металлического лома имеет компактную конструкцию и занимает минимальное пространство на полу, что делает её особенно подходящей для небольших и средних перерабатывающих предприятий с ограниченным пространством.

Параметры машины для прессования металлического лома

Мы предлагаем широкий ассортимент металлических гидравлических прессов с более чем дюжиной моделей, охватывающих конфигурации от маломасштабных до тяжелых. Независимо от того, управляете ли вы недавно созданным перерабатывающим предприятием или заводом по переработке металлов высокой мощности, мы можем предложить решение, соответствующее вашим потребностям. Ниже приведены ключевые технические характеристики нескольких представительных моделей:

| Модель | Сила толкания | Сжатый склад (мм) | Размер пресс-подборщика (мм) | Эффективность (кг/ч) | Мощность (кВт) |

| Y81-1250A | 1250 | 1200*700*600 | 300*300 | 1200-1800 | 15 |

| Y81-1350 | 1350 | 1400*600*600 | 600*240 | 1600-2500 | 18.5 |

| Y81-1600B | 1600 | 1600*1200*800 | 400*400 | 2000-4000 | 30 |

| Y81-2000B | 2000 | 1800*1400*900 | 450*450 | 3000-5000 | 30/37 |

| Y81-2500D | 2500 | 2500*2000*1200 | 600*600 | 5500-6500 | 60 |

| Y81-3150D | 3150 | 3000*2500*1200 | 600*600 | 6000-8000 | 90 |

| Y81-4000C | 4000 | 3500*3000*1200 | 600*600 | 9500-14000 | 90 |

Мы также предлагаем настройку размера тюков, уровня автоматизации и дизайна компоновки. Если у вас есть конкретные требования, не стесняйтесь обращаться к нам за персонализированной технической поддержкой и подробной сметой.

Как мы предоставляем наиболее подходящий металлопресс для наших клиентов

Мы рекомендуем правильную модель и конфигурацию на основе типа сырья клиента, ежедневного объема, пространства на заводе и требований к размеру тюков. Независимо от того, обрабатываете ли вы крупные металлические отходы или мелкие металлические стружки, или нуждаетесь в тюках определенных размеров и форм, мы предлагаем индивидуальные решения для удовлетворения каждой потребности. Клиентам необходимо лишь поделиться своими основными требованиями, и мы оперативно предоставим предложения по моделям, планы размещения и ссылки на инвестиции, чтобы обеспечить точный выбор и эффективную работу.