Sink Float Plastic Separation

Our sink float plastic separation is a specially designed machine for PET bottle washing plants to clean and separate mixed plastics. Its main function is to effectively separate PET bottle flakes from labels or caps made of PP, PE, etc.

Our sink float plastic separation is a specially designed machine for PET bottle washing plants to clean and separate mixed plastics. Its main function is to effectively separate PET bottle flakes from PVC labels or PP caps, to provide clean raw materials for subsequent processing.

Our sink float separation tank is designed to be advanced and easy to operate, with excellent separation efficiency and processing capacity. The equipment is made of high-quality materials with high durability to ensure long-term stable operation. In addition, we offer customized services to adjust and optimize the equipment according to customers’ specific needs.

Features of Plastic Flakes Washing Machine

- Effective separation: It can efficiently separate PET bottle flakes and PP bottle caps to ensure the quality of the final flakes.

- Polyolefin control: Control polyolefin content at ≤200-300mg/kg to meet reuse standards.

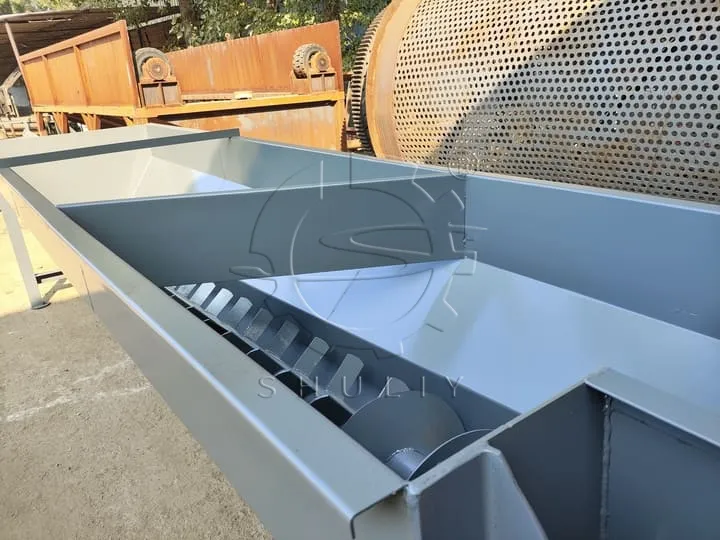

- Deep washing tank: For lighter PET bottle flakes, a deeper cleaning tank is designed to ensure effective separation.

- Customization: It can be customized according to customers’ needs and flexibly adapted to different PET washing lines.

Sink Float Separation Tank Application Video

Working Principle of Sink Float Plastic Separation

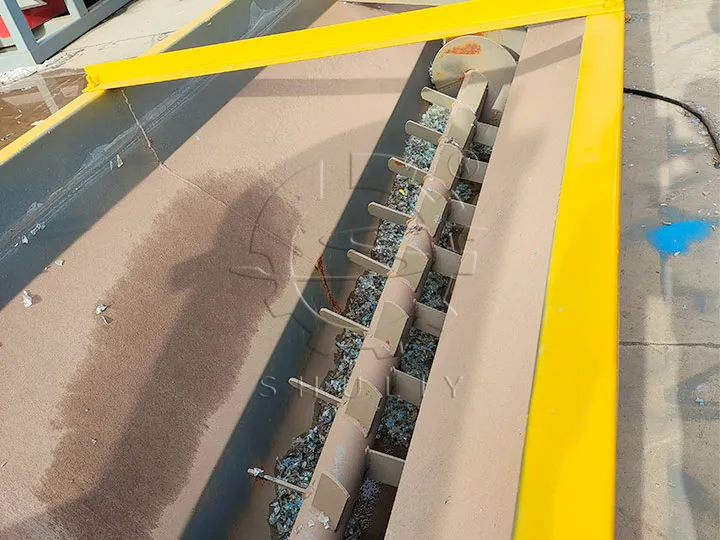

The machine uses water as the medium and utilizes the density difference for separation. When the mixed plastics enter the sinking and floating separation tank, the PET plastic will sink to the bottom of the tank because its density is greater than that of water, and the bottom screw conveys the bottle flakes to the next process; whereas the PP bottle cap floats on the surface of the water, and is discharged through the outlet on the side of the machine. In this way, the effective separation of mixed plastics is achieved.

Configuration Recommendations For Sink Float Separation Tank

The number of sink float plastic separations depends on the level of plastic contamination, the specific needs of the customer, and the production volume. Typically, this machine is installed after the automatic plastic bottle crusher to separate caps and residual labels from PET bottle flakes.

If product quality is more important or the production volume is larger, it is recommended to install one or two PET bottle flakes washing machines after the hot wash tank. This effectively rinses off the detergent brought out of the hot wash tank, reduces the PVC content, and further separates impurities.

Parameters of Sink Float Plastic Separation

To prevent lightweight bottle flakes from not being able to sink, and to avoid them being carried out when removing PP caps, we have deepened and widened the cleaning tank. Below is the detailed parameter information for the sink float separation tank.

- Length: 6.0m

- Width: 1.2m

- Height: 1.2m

- Motor power: 3kw, three-phase 380V50Hz

- Outer wall thickness: 4mm

- Blade thickness: 6mm

Other PET Flakes Washing Machine

In addition to sink float plastic separations, our company also offers PET flakes washing machines such as hot washed PET flakes machines and friction washers. These machines work in conjunction with other PET bottle recycling machines to form a complete PET bottle washing line. We also provide customized solutions to flexibly configure the cleaning line according to the customer’s needs and production scale to achieve the best cleaning effect and production efficiency.