Tire Cutting Machine

Our robust tire cutting machine, also known as a tire cutter, is an essential component for any high-efficiency…

Our robust tire cutting machine, also known as a tire cutter, is an essential component for any high-efficiency tire recycling line. Designed to operate after the bead wire has been removed, its primary role is to cut whole, debeaded tires into smaller, more manageable segments, typically under 900mm in size. This crucial pre-processing step significantly enhances the speed, efficiency, and longevity of your primary shredder, making it a smart investment for optimizing your entire workflow.

We offer two distinct models to handle everything from standard truck tires to massive OTR tires, ensuring we have the right solution for your specific operational scale.

The Advantage of Pre-Cutting Tires

Feeding whole, debeaded tires directly into a tire shredder machine can be inefficient. The round shape makes it difficult for the shredder’s blades to get a consistent grip, often causing the tire to bounce in the hopper. By cutting the tire into 3-4 smaller pieces first, you gain several key advantages:

- Increased Shredder Throughput: Smaller, flatter tire segments are much easier for the shredder to grab and process, dramatically increasing your hourly output.

- Reduced Wear and Tear: Pre-cutting reduces the initial strain on the shredder’s motors, shafts, and blades, leading to a longer service life and lower maintenance costs.

- Improved Energy Efficiency: The shredder consumes less power when processing consistently sized feedstock compared to wrestling with whole tires.

- Stable and Continuous Operation: A steady flow of pre-cut segments ensures a smoother, more predictable shredding process with less downtime.

Working Principle of the Tire Cutting Machine

This tire cutting equipment utilizes powerful hydraulic force to efficiently and safely cut tires into blocks smaller than 900mm in a simple three-step operation.

- Tire Placement: The operator places the debeaded tire on the machine’s cutting platform and adjusts it to the correct cutting position.

- Tire Clamping: When activated, a hydraulic clamping device automatically presses down to hold the tire firmly against the base. This prevents it from slipping or shifting during the cut, ensuring both operational safety and cutting accuracy.

- Hydraulic Cutting: With the tire secured, the main cutting cylinder drives the alloy steel blade downward with immense shearing force, instantly cutting the tire. After the cut is completed, the blade automatically retracts, allowing the operator to move the tire and repeat the operation until the entire tire is divided into the desired segments.

Working Video of Tire Cutter Machine

Our Tire Cutting machine Models for Every Application

To meet the demands of different recycling facilities, we have developed two specialized hydraulic tire cutting machines.

Standard Tire Cutter Machine (For Tires up to 1200mm)

This model is the perfect solution for facilities processing debeaded truck, bus, and other commercial vehicle tires. Its powerful hydraulic shear and durable blade make quick work of thick rubber, efficiently cutting tires into uniform blocks ready for the shredder. Its compact design and high output make it an ideal fit for most standard tire recycling plants.

| Specification | Details |

| Model | Standard Tire Cutting Machine |

| Applicable Tire Size | 900mm – 1200mm (debeaded) |

| Power | 7.5 kW |

| Capacity | Approx. 60 tires per hour |

| Blade Material | Chromium 12 Molybdenum Vanadium (Cr12MoV) |

| Dimensions (LWH) | 1.7m * 0.8m * 1.85m |

| Weight | 1400kg |

Heavy-Duty OTR Waste Tyre Cutting Machine

Recycling giant Off-the-Road (OTR) tires requires equipment built for extreme duty. Our OTR tire cutting machine is engineered specifically for this challenge. With a heavily reinforced frame, a powerful hydraulic system, and an oversized cutting jaw, it can effortlessly shear through the thickest sections of debeaded mining, construction, and agricultural tires. This machine is indispensable for any facility serious about processing large-scale tires.

| Specification | Details |

| Model | OTR Tire Cutter |

| Applicable Tire Size | 1400mm – 4000mm (debeaded) |

| Power | 7.5 kW |

| Capacity | Approx. 2 cuts per minute |

| Blade Material | Chromium 12 Molybdenum Vanadium (Cr12MoV) |

| Dimensions (LWH) | 3.13m * 1.65m * 2.7m |

| Weight | 7200 kg |

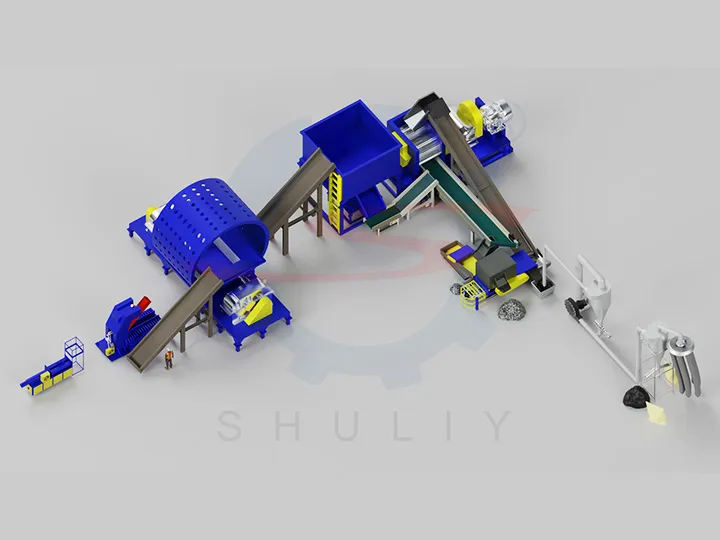

Form a Complete Rubber Powder Production Line

This tire cutting machine can work together with the tire debeader machine, tire shredder, and rubber crusher machine to form a complete rubber powder production line. By cutting, shredding, and grinding in sequence, waste tires can be efficiently recycled into high-quality rubber powder, which can be used for producing reclaimed rubber products, floor mats, running tracks, and other applications.

Whether you require a tyre cutting machine or a complete tyre recycling line, we can provide you with a solution. Please contact us immediately.