Tire Dismantling Machine

Tire dismantling machine is an essential equipment in modern tire recycling plants. It is designed to cut and…

Tire dismantling machine is an essential equipment in modern tire recycling plants. It is designed to cut and separate waste tires, remove the steel bead, and dismantle the tire into smaller sections for easier processing. Whether you are handling truck tires, bus tires, or large OTR (off-the-road) tires, a tire dismantling machine improves efficiency and prepares the material for tire shredders, crushers, and rubber powder production lines.

Our Tire Dismantling Machine Models

We provide specialized equipment tailored to the types of tires you process.

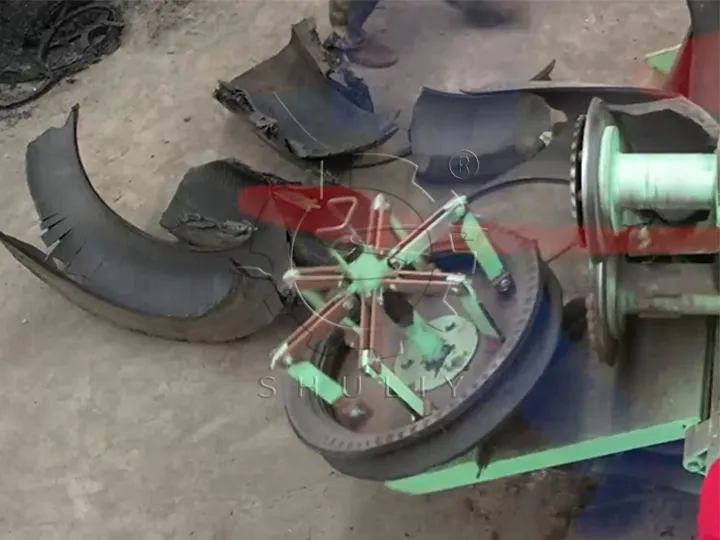

Tire Bead Removal and Cutter Machine

For tires with a diameter below 1200mm, we offer a tire bead removal and cutter machine.

- Integrated Design: This machine combines bead removal and tire cutting in one step.

- High Efficiency: It can directly separate the steel bead and cut truck tires in a single pass.

- Compact Structure: Small footprint, easy to operate, suitable for truck tire recycling plants.

tire sidewall remover and cutter machine Technical Specifications

| Specification | Details |

| Model | Tire Steel Ring Removing + Cutting Machine |

| Power | 7.5 + 3 kW |

| Capacity | Approx. 3 tons per hour |

| Blade Material | Chromium 12 Molybdenum Vanadium (Cr12MoV) |

| Applicable Tire Size | 900mm – 1200mm tires |

| Dimensions (LWH) | 2.45m * 1m * 1.7m |

| Weight | 1500 kg |

Working Video of The Tire Dismantling Machine

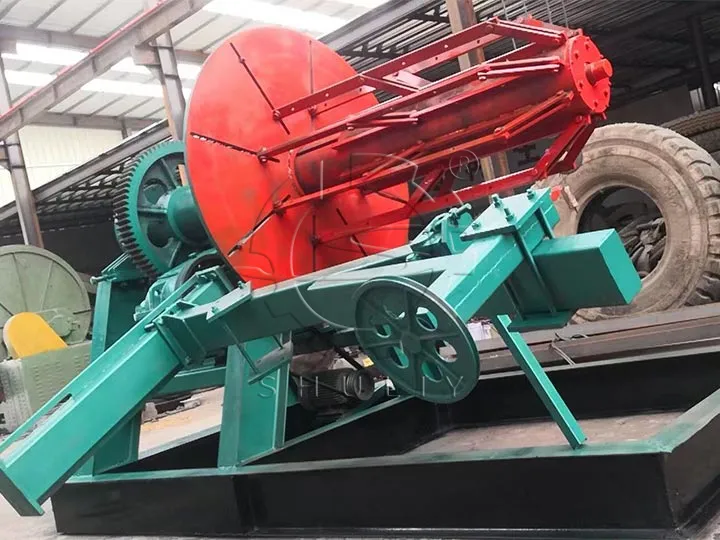

Heavy-Duty OTR Tire Dismantling Machine

- Multi-Part Separation: Cuts the tire into 4–6 parts including bead, tread, and crown for easier handling.

- Powerful Cutting System: 30.5kW motor ensures stable and efficient operation.

- Durable Blades: Tungsten carbide alloy blades with long service life and consistent cutting performance.

We offer two models to handle different size ranges.

Model for 1400mm – 2000mm OTR Tires:

| Specification | Details |

| Model | OTR Dismantling Machine |

| Applicable Tire Size | 1400mm – 2000mm tires |

| Power | 7.5 + 5.5 kW |

| Capacity | 7-15 minutes per tire |

| Blade Material | Tungsten Steel Alloy |

| Dimensions (LWH) | 4.35m * 3.8m * 2.4m |

| Weight | 5600 kg |

Model for R35 – R63 Giant OTR Tires:

| Specification | Details |

| Model | OTR Dismantling Machine (Large) |

| Applicable Tire Size | R35 (approx. 2100mm) – R63 |

| Power | 30.5 kW |

| Capacity | 10-30 minutes per tire |

| Blade Material | Tungsten Steel Alloy |

| Dimensions (LWH) | 7.25m * 3.8m * 2.98m |

| Weight | 9900 kg |

Working Video of OTR Dismantling Machine

Why Dismantle a Tire Instead of Just Shredding It?

Systematically dismantling a tire offers significant advantages over direct shredding:

- Material Segregation: It allows you to cleanly separate the bead wire sections (high in steel) from the purer rubber of the tread and sidewalls.

- Increased Shredder Efficiency: Feeding smaller, pre-processed sections into a shredder is far more efficient than feeding whole tires. It increases throughput and reduces energy consumption.

- Extended Equipment Life: By removing the toughest parts of the tire first, you significantly reduce the wear and tear on your primary shredder’s expensive blades and components.

- Higher Value Output: Separated components are often more valuable than a mixed shredded output. Clean rubber and steel can be sold as distinct commodities.

Application in Tire Recycling Line

A tire dismantling machine is typically used as the first step in a rubber powder production line:

- Tire Dismantling Machine – Removes bead and cuts tires into sections.

- Steel Wire Separator – Further separates remaining steel from rubber.

- Tire Shredder – Reduces tire sections into chips.

- Rubber Powder Machine – Produces fine rubber powder or crumb rubber for reuse.

Advantages of Our Tire Dismantling Machines

- Suitable for truck tires, bus tires, and large OTR tires.

- Reduces manual labor and improves processing efficiency.

- Heavy-duty design, reliable hydraulic system, and easy operation.

- Customizable solutions to match factory layout and production capacity.

Choose the Right Solution for Your Recycling Line

A tire dismantling machine is a must-have for any tire recycling plant. It saves labor, reduces tire volume, and ensures smooth feeding into shredders and milling machines. Whether you are recycling truck tires or processing OTR tires for rubber powder production, selecting the right dismantling solution will help you build an efficient and cost-effective tire recycling line.