Tire Sidewall Cutter

Our tire sidewall cutter is an efficient and durable pre-processing machine for scrap tires. Its core function is…

Our tire sidewall cutter is an efficient and durable pre-processing machine for scrap tires. Its core function is to completely cut and remove the tire bead section from the sidewall, which contains the thick, heavy-duty steel wire, before the tire moves to subsequent processing stages. As a key initial machine in a semi-automatic rubber powder production line, it removes the toughest obstacle for the downstream strip and block cutters, ensuring the smooth operation and safety of the entire line. It is an indispensable first step for improving tire recycling efficiency.

Why is Sidewall Cutting the First Step?

The bead of a scrap tire contains a bundle of high-strength steel wires, making it the toughest and most difficult part of the entire tire to process.

- Protects Downstream Equipment: If not removed first, this hard steel bead wire will cause severe wear and tear on, or even damage to, the blades of the subsequent tire recycling machines.

- Improves Efficiency: Simplifies the overall process by removing the toughest component first, making subsequent steps faster and easier.

- Maximizes Material Value: The separated tire bead can be fed into a dedicated Bead Wire Separator to completely divide the rubber from the intact steel wire hoop. This clean steel wire can be sold as high-grade scrap steel, fetching a higher price.

Working Principle & Operation of Tire Sidewall Cutter

Our tire sidewall cutter is designed for simplicity and intuitive operation, requiring minimal technical skill.

1. Placement

Manually place the whole scrap tire onto the machine’s horizontal turntable.

2. Positioning the Blade

Start the machine and use the control lever to lower the cutting blade, made of high-hardness alloy steel, precisely onto the tire’s sidewall.

3. Rotary Cutting

The turntable rotates the tire at a steady speed. As it turns, the stationary blade makes a smooth and rapid cut along a preset path, completely severing the sidewall.

4. Separation

Once the cut is complete, raise the blade and remove the separated tire bead and the main tire body. The entire process is highly efficient, typically completed in under a minute.

Working Video of Tire Ring Cutter

Key Advantages & Features of Tire Bead Cutting Machine

- Precise and Efficient Cutting: The specialized design ensures cutting accuracy and stability, resulting in a clean cut and complete separation.

- Durable Cutting Blade: The blade is crafted from a special wear-resistant hard alloy steel and is heat-treated for high hardness and a long service life.

- Wide Applicability: Suitable for passenger car tyres and truck tyres with diameters up to 1200mm, and can be customized to accommodate the customer’s tyre diameter.

- Low Energy Consumption and Small Footprint: Compared to large shredders, this tire sidewall cutter consumes less power and requires minimal floor space, making it ideal for small to medium-sized or semi-automatic tire recycling plants.

Role in a Semi-Automatic Rubber Powder Production Line

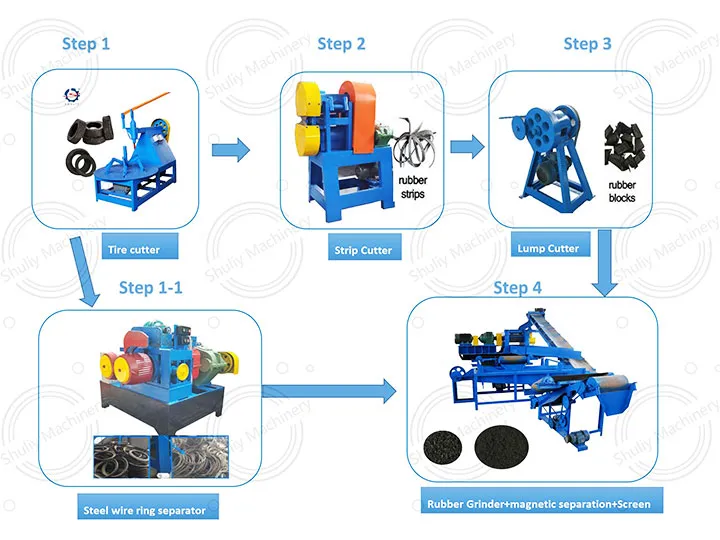

The Tire Sidewall Cutter is the “key” that starts the entire semi-automatic rubber powder production line. A typical workflow is as follows:

1. Step 1: Cutting

- Whole Tire → Tire Sidewall Cutter → Separates into ① Tire Bead and ② Main Tire Body

2. Step 2: Sizing

- Main Tire Body → Tire Strip Cutter → Tire Block Cutter → ~50mm Rubber Blocks

3. Step 4: Bead Processing

- Tire Bead → Bead Wire Separator → Separates into clean steel wire and rubber

4. Step 3: Grinding

- Rubber Blocks → Rubber Cracker Mill → Final Rubber Powder

Technical Specifications of Tyre Bead Cutting Machine

| Item | Parameter |

| Applicable Tire Range | 650 – 1200 mm (Customizable) |

| Capacity | Approx. 40Tires/Hour |

| Motor Power | 4KW+0.75KW |

| Blade Material | Hard Alloy Steel |

| Dimensions (LWH) | 1.8m*1.3m*1.6m |

| Weight | 650kg |

Note: The above specifications are for a standard model. We offer customization based on the type and size of tires you need to process.

Contact Us to Configure Your Tire Recycling Line

As a professional manufacturer of recycling machinery, we understand the importance of every pre-treatment stage. A reliable tire sidewall cutter will lay a solid foundation for the streamlined operation of your entire tire recycling business.

If you are planning a semi-automatic tire recycling line or wish to upgrade your existing pre-processing equipment, contact us today. We will provide comprehensive support, from equipment selection to production line layout.