Tire Steel Wire Separator

The tire steel wire separator is an essential machine in waste tire recycling lines. It is specially designed…

The tire steel wire separator is an essential machine in waste tire recycling lines. It is specially designed to process the bead rings cut from tires by a bead cutter, separating the embedded steel wires from the rubber. As part of a complete tire recycling machine setup, this equipment improves efficiency and ensures cleaner rubber output for further processing.

To meet the diverse needs of the tire recycling market, we have specially designed and now offer two different models of tire bead wire remover machines to provide the most efficient solution for your business.

The first is our standard model, engineered to process tires with a diameter of up to 1200mm, such as those from trucks, buses, and some industrial vehicles, ensuring efficient and stable separation. The second is our heavy-duty OTR steel ring separator, which is dedicated to handling large-scale off-the-road (OTR) tires. Considering the immense size and robust construction of OTR tires, this model has been comprehensively reinforced in terms of power, structural strength, and operational performance.

Why is the Separation of Steel and Rubber Crucial?

In the tire recycling process, the tire bead is one of the most robust and difficult components to handle. If not separated effectively, it can lead to several problems:

- Damage to Downstream Equipment: Intact steel bead wires can cause severe wear and even damage the blades of subsequent rubber tire shredders and rubber crushers, leading to increased maintenance costs and production downtime.

- Reduced Material Value: Scrap steel contaminated with rubber fetches a lower price in the smelting market. Similarly, rubber powder or crumb rubber containing steel wire impurities is of lower quality, limiting its applications and reducing its market value.

- Increased Processing Efficiency: Pre-separating the steel wire allows for smoother and more efficient downstream shredding and grinding of the rubber, boosting the overall throughput of the entire tyre processing plant.

Working Principle of Tire Steel Wire Separator

The machine operates with two counter-rotating rollers running at the same speed. When the tire bead ring is fed into the gap between the rollers, it is compressed, squeezed, and torn repeatedly until the steel wire is completely separated from the rubber. This mechanical process ensures effective separation and prepares the material for subsequent steps such as shredding, or rubber powder milling.

Tire Wire Removal Machine Working Video

Main Features of Tire Steel Wire Separator

- Effective Separation: Designed to handle tire bead rings and separate steel wire with high efficiency.

- Durable Structure: Robust rollers and frame ensure stable operation and long service life.

- Easy Operation: Simple feeding process with reliable separation results.

- Support for Recycling Lines: Works in combination with bead cutters, tire shredders, and rubber powder machines.

Models and Technical Specifications of Tyre Wire Removal Machine

We offer two different models of steel wire separators to precisely meet your specific processing requirements. From standard truck tires to giant OTR tires, we have a dedicated solution for every scale of operation.

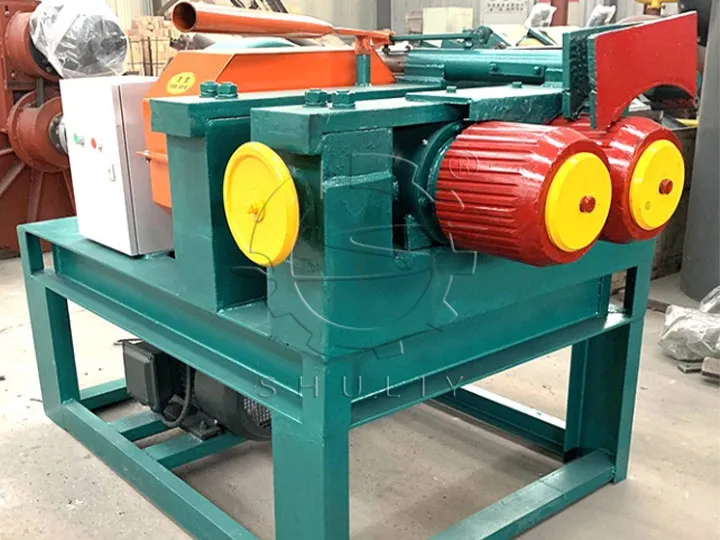

Standard Model: Tire Steel Wire Separator

This standard model is the ideal choice for processing regular-sized tires, suitable for truck, bus, and other tires with a diameter of up to 1200mm. It utilizes two counter-rotating rollers to powerfully extrude, shear, and tear the tire rim, efficiently separating the steel from the rubber. This makes it a fundamental piece of equipment for high-efficiency operations in tire recycling plants.

| Technical Specifications | Details |

| Total Power | 18.5 KW |

| Capacity | Approx. 120 rims/hour |

| Dimensions (LWH) | 2m * 1.9m * 1.8m |

| Weight | 1800 kg |

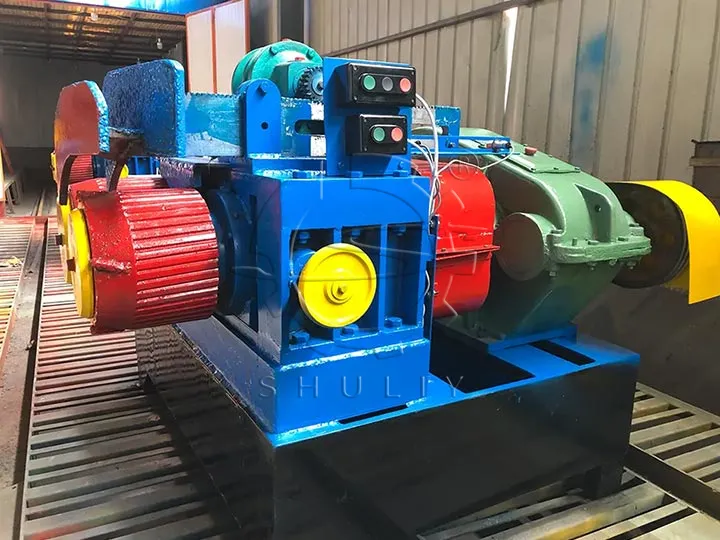

Heavy-Duty Model: OTR Tire Wire Removal Machine

Specifically engineered for large-scale off-the-road (OTR) tires, this heavy-duty model features a more robust structure and a more powerful drive system. It is capable of processing the rims of giant tires ranging from 1400mm to 4000mm in diameter. Faced with the tough and thick steel wire found in OTR tire beads, this tire steel wire separator can reliably and completely perform the separation task, making it an indispensable piece of equipment for large-scale tire recycling facilities.

| Technical Specifications | Details |

| Model No. | OTR tyre wire removal machine |

| Total Power | 35.5 KW |

| Capacity | Approx. 2-5 minutes per rim |

| Dimensions (LWH) | 3.65m * 2.1m * 1.95m |

| Applicable Range | Rims from 1400mm – 4000mm tires |

| Weight | 6200 kg |

Applications in Tire Recycling

The tire steel wire separator is widely used in:

- Waste tire recycling plants – to remove bead wires efficiently

- Rubber powder production lines – preparing clean rubber material for milling

- Scrap tire processing facilities – reducing wear on shredders and grinders by removing steel first

By ensuring that the steel is cleanly separated from rubber, the machine helps extend the lifespan of downstream equipment and improves the quality of recycled rubber.

Key Equipment for Enhancing Tyre Recycling Efficiency

As an important tire processing equipment, the tire steel wire separator offers an efficient solution for bead wire removal in waste tire recycling. Its reliable operation and integration with other machines such as bead cutters, tire shredders, and rubber powder mills make it a valuable part of a complete tire recycling line.

If you are planning to set up or upgrade a tire recycling plant, this machine can help improve processing efficiency and product quality.