Tire Strip Cutter

Tire strip cutter is an essential machine in the waste tire recycling process. It is usually installed after…

Tire strip cutter is an essential machine in the waste tire recycling process. It is usually installed after the tire bead cutter, used to cut waste tires (with bead removed) into strips. These rubber strips are then fed into the tire block cutter and later processed by the rubber powder mill, forming part of a semi-automatic tire recycling line for rubber powder or granules production.

Application in Tire Recycling Line

In a semi-automatic tire recycling process, each step serves the next. Cutting the tire into strips is a critical intermediate step:

- Connects to Upstream Processing: It handles tires that have already been processed by a tire sidewall cutter machine, meaning the toughest bead sections have been removed.

- Serves Downstream Equipment: The long strips are the ideal feedstock for the tire block cutter. Standard-width strips ensure that the block cutter can operate efficiently and stably, producing uniformly sized rubber blocks.

- Improves Overall Line Efficiency: As a dedicated process, it ensures that the material has a consistent shape before moving to the next stage. This prevents blockages or drops in efficiency caused by irregular material, thus improving the overall flow of the production line.

Features of Tire Strip Cutter

- Consistent cutting size: Produces uniform rubber strips suitable for the next stage.

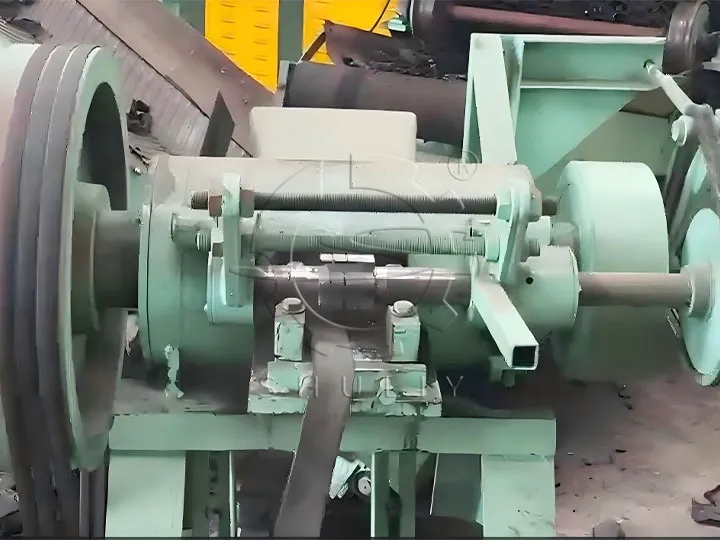

- Stable performance: Designed with durable blades and a simple operating structure.

- Wide adaptability: Suitable for truck tires, car tires, and other waste rubber tires.

- Easy operation and maintenance: Simple control system with low maintenance requirements.

Key Advantages & Features of Tyre Strip Cutting Machine

- High-Efficiency Continuous Operation: Engineered for continuous cutting at high speed, it effectively matches the pace of the entire semi-automatic line, boosting overall capacity.

- Durable Alloy Blades: The core disc blades are crafted from a special hard alloy steel that undergoes precision machining and heat treatment for exceptional wear resistance and strength. They have a long service life and can be re-sharpened.

- Adjustable Strip Width: The width of the rubber strips can be easily changed (typically between 3-5 cm) to meet different production requirements.

- Easy Maintenance: The machine’s clear and simple structure makes daily maintenance and servicing convenient, helping to lower long-term operating costs.

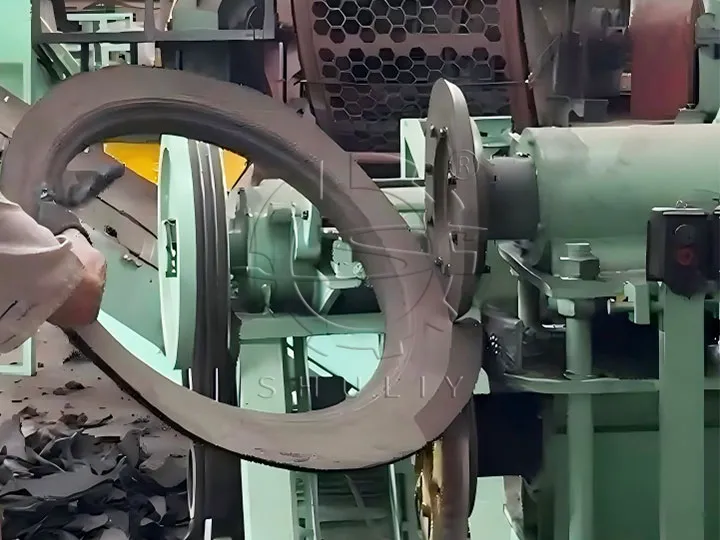

working Video of Tire Strip Cutter

Tire Strip Cutting Machine Technical Specifications

| Item | Parameter |

| Material to be Processed | Debeaded Scrap Tires |

| Capacity | 1000kg/h |

| Strip Width | 30 – 50 mm (Adjustable) |

| Motor Power | 5.5KW |

| Blade Material | Hard Alloy Steel |

| Dimensions (LWH) | 1.3m*0.8m*1.65m |

| Weight | 850kg |

Note: The above specifications are for a standard model. We offer customization based on your specific capacity and material requirements.

Related Machines

A complete semi-automatic tire recycling line often includes:

- Tire bead cutter – removes the steel wire ring.

- Tire strip cutter – cuts tires into strips.

- Tire block cutter – cuts strips into blocks.

- Tire steel wire separator – separation of the tyre bead from the steel ring.

- Rubber powder machine / rubber crusher – grinds blocks into rubber powder or granules.

Tire Recycling Machine For Sale

As a professional manufacturer of tire recycling machinery, we are committed to providing our clients with complete solutions, from single machines to full rubber powder production lines. A reliable tire strip cutter is a vital component for the efficient operation of your semi-automatic line.

If you are planning or upgrading your tire recycling project, contact our technical experts today. We will provide you with the most professional equipment selection advice and production line layout plans.