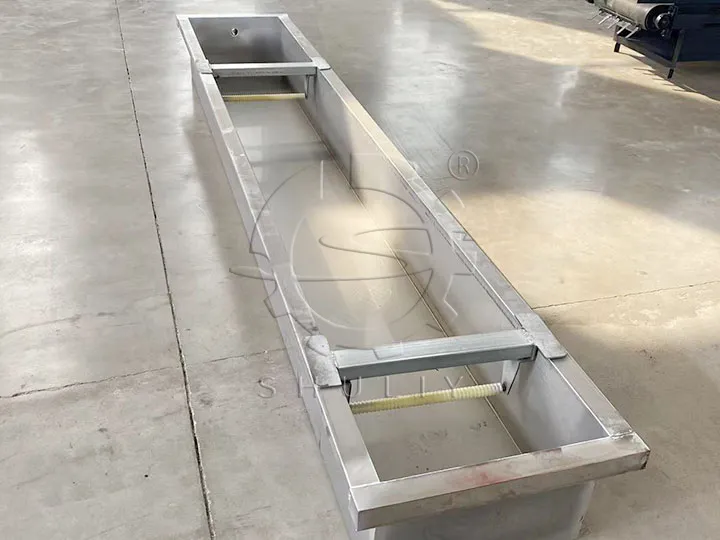

Plastic Cooling Tank

The plastic cooling tank is located at the rear of the plastic pelletizer machine and is used to cool and solidify the plastic strips extruded from the pelletizer in preparation for subsequent cutting into smaller pellets.

The plastic cooling tank plays a vital role in the process of plastic pellet manufacturing. It is located at the back of the plastic pelletizer machine and is used to cool and solidify the lengths of plastic extruded from the pelletizer in preparation for subsequent cutting into smaller pellets.

Plastic Cooling Tank Application Video

Introduction of Cooling Tank

A cooling tank is a vessel, usually made of stainless steel, used to cool thermoplastic lengths extruded from a plastic pelletizer machine. Its design takes into account the morphology of the plastic strip and the process requirements to ensure efficient cooling and curing.

Size and Customization

The regular dimensions of the plastic cooling tank are 2.5 meters long and 0.4 meters wide. However, we also offer customized services to suit different production processes and requirements. Depending on the customer’s needs, the size and design of the cooling trough can be adjusted to ensure optimum productivity and product quality.