PET Bottle Scrap Machine Running in South Sudan: Recycling of Water And Beer Bottles

In this video, we showcase our PET bottle scrap machine in operation at a client’s recycling facility in South Sudan. The machine efficiently processes waste water and beer bottles, turning them into high-quality PET flakes. These flakes will be further processed into recycled plastic pellets for reuse in various applications.

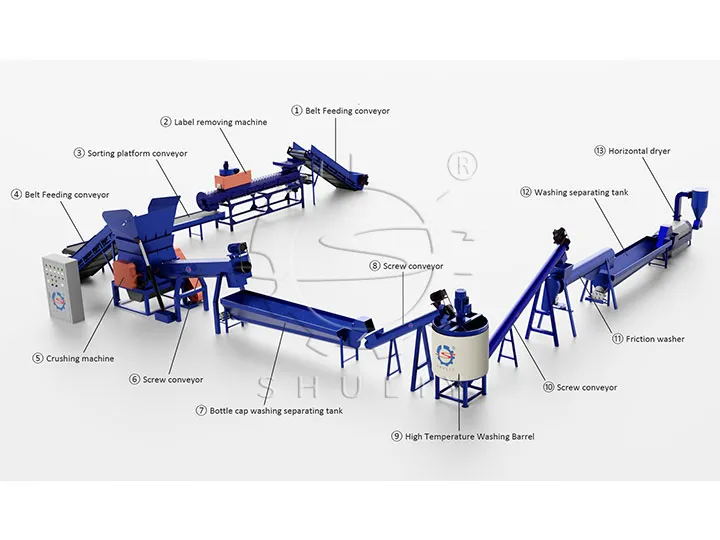

PET Recycling Process

The video takes you through the step-by-step PET recycling process, demonstrating how waste PET bottles are transformed into reusable materials.

Specific process: Label Removal-Shredding-Float-Sink Separation-Hot Washing-Friction Washing-Drying-Pelletizing

PET Bottle Scrap Machine Customization Options

Customized throughput

PET bottle Recycling lines with different throughputs from 500kg/h – 6000kg/h are available according to customer requirements.

Sieve Mesh Aperture

Customized PET bottle crusher screen apertures are available to control bottle size, such as 12mm, 14mm, 16mm, etc.

Cleaning Programme

Depending on the degree of contamination of the raw material, increase or decrease the cleaning steps such as hot washing, friction washing, and rinsing.

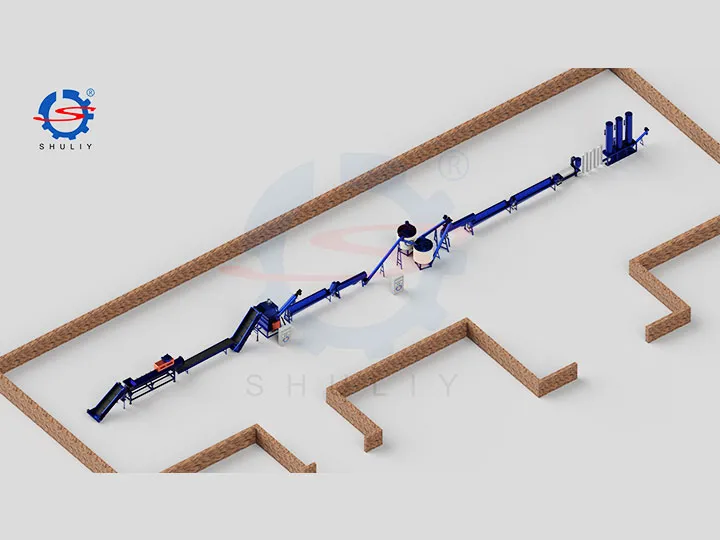

Equipment Layout

According to the size of the customer’s plant, adjust the layout of the PET bottle scrap machine, so that the placement of equipment is more reasonable.

Degree of Automation

Provides options such as automatic loading and automatic packaging to improve productivity.

Contact Us For Customized Solutions

In addition to the ones listed above, if you have any other questions or requests, you can ask them and our sales managers will give you the most professional advice. You can leave your contact information in the pop-up window in the lower right corner, we will contact you as soon as possible.