Rubber Crusher Machine

A rubber crusher machine, also known as a tire grinder or rubber powder mill, is a vital piece…

A rubber crusher machine, also known as a tire grinder or rubber powder mill, is a vital piece of equipment in the waste tire recycling industry. Its primary function is to take pre-processed tire blocks (typically 30-100mm) and meticulously grind them down into fine rubber powder. During this process, our system also incorporates powerful screening and magnetic separation steps to remove steel wire and nylon fibers, ensuring a final product of exceptional purity and quality.

How Our Tire Rubber Crusher Works:

Our integrated rubber powder production line simplifies the recycling process, ensuring maximum efficiency and output quality.

- Feeding: Tire blocks pre-processed by the tire shredder are fed into the system via a conveyor belt.

- Grinding & Milling: The blocks enter the main crusher, where high-speed rotating blades and fixed blades shear and grind the rubber into smaller particles.

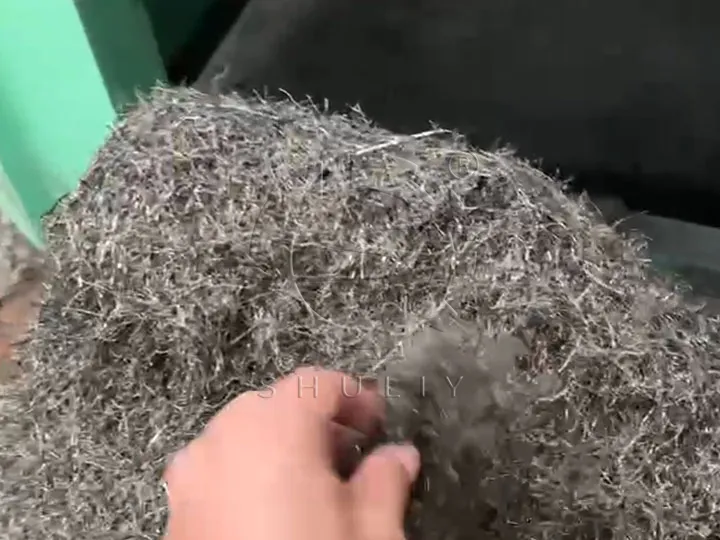

- Separation: The ground material passes through a magnetic separator to extract any residual steel wire. An additional screening or fiber separation system removes nylon and other impurities.

- Sieving & Collection: The pure rubber particles are sieved to achieve the desired mesh size (e.g., 5-40 mesh) and then collected as the final product, ready for sale or further use.

Working Video of The Rubber Crusher Machine

Key Features & Benefits of Our Rubber Powder Mill

- High Purity Output: Advanced magnetic and fiber separation systems guarantee the removal of steel and nylon, producing clean rubber powder with high market value.

- Versatile Output Size: Easily process 30-100mm tire blocks into a wide range of particle sizes, from 5 to 40 mesh, catering to diverse market demands.

- Robust & Durable Construction: Built with high-quality materials to withstand the rigors of continuous operation, ensuring long service life and minimal downtime.

- Efficient & Scalable Production: With a wide range of models, our machines offer capacities from 80 kg/h to over 2,300 kg/h, allowing you to choose the perfect solution for your production scale.

- Customized Solutions: We understand that every operation is unique. We design and build rubber crusher machines tailored to your specific raw materials, capacity needs, and factory layout.

Technical Parameters of Rubber Cracker Mill

| Parameter | Description |

| Product Name | Rubber Crusher Machine |

| Input Material | Shredded or Cut Tire Blocks |

| Input Size | 30 – 100 mm |

| Final Product | High-Purity Rubber Powder / Granules |

| Output Size | 5 – 40 Mesh |

| Separation Function | Automatic separation of steel wire & nylon fiber |

Note: The specific capacity varies depending on the final output mesh size. Finer mesh sizes result in lower capacity. Please contact us for a precise configuration based on your requirements.

Applications of Recycled Rubber Powder

The high-quality rubber powder produced by our rubber crusher machine has numerous profitable applications, including:

- Modified Asphalt: Improving road durability and longevity.

- Sports Surfaces: Creating athletic tracks, playground surfaces, and artificial turf infill.

- Rubber Tiles & Flooring: Manufacturing durable and non-slip flooring for gyms and commercial spaces.

- Waterproof Materials: Used in construction for sealing and waterproofing membranes.

- Automotive Parts: Molded into new rubber products like mats and bumpers.

From a Single Machine to a Full Production Line

Beyond providing a high-quality rubber crusher machine, we specialize in delivering comprehensive tire recycling solutions. Whether you are just starting or looking to upgrade, we have the expertise to design a complete rubber powder production line that fits your goals.

- Tell Us Your Goal: How do you want to process tires? Are you starting with whole tires or pre-shredded blocks?

- We Design the Solution: Based on your specific needs, budget, and factory layout, we can design and configure a semi-automatic or fully automatic production line. Our solutions cover the entire process, from initial pre-processing equipment and tire shredding machines to fine grinders, separation systems, and even final packaging equipment.

- You Get a Turnkey System: Our mission is to provide you with a seamless, efficient, and profitable system tailored precisely to your operational requirements.

Get Your Custom Tire Recycling Solution Today!

Our team of experts is ready to help you design the perfect rubber crusher machine or complete tire recycling plant for your business goals. We provide not just equipment, but a complete solution tailored to your needs.

Contact us today to discuss your project and receive a free, no-obligation quote!