PET Bottle Label Remover Machine

PET bottle label remover machine is the first process in the PET bottle recycling line, its main function is to effectively separate PET bottles from the label attached to their surfaces. This paper introduces the role of the machine, the working principle, and so on.

PET bottle label remover machine is a device used to remove labels from PET bottles. Removing the label on PET bottles is an important step in the recycling and reuse process, as the label is not made of PET material and can affect the quality of recycled PET bottle sheets. Plastic bottle label removing machines typically use mechanical or chemical methods to remove labels from bottles for subsequent cleaning and reuse.

The PET bottle label removing machine is made of sturdy and durable materials for stable operation and is capable of handling various types and sizes of PET bottles. Its label separation rate is extremely high, with a label separation efficiency of 98% -99% for round bottles and 85% -90% for flat bottles. This efficient label removal capability significantly improves the quality of PET bottle recycling.

PET Bottle Label Remover Machine Introduction

The plastic bottle label removing machine is the first process in the PET bottle recycling line, its main function is to effectively separate PET bottles from the labels attached to their surfaces, and provide clean bottle raw materials for the subsequent recycling process.

By separating the PET bottle from the label, the PET bottle label remover machine helps to ensure the quality and purity of the recycled material, making the reused PET material more suitable for use in the production of new PET bottles, fibers, garments, and other products.

Advantages of Our Label Remover Machine

- Automatic removal of PVC labels: The equipment can automatically and efficiently remove PVC labels from bottles, which significantly saves labor costs, effectively reduces the PVC content in PET bottle flakes, and improves the quality of recycled materials.

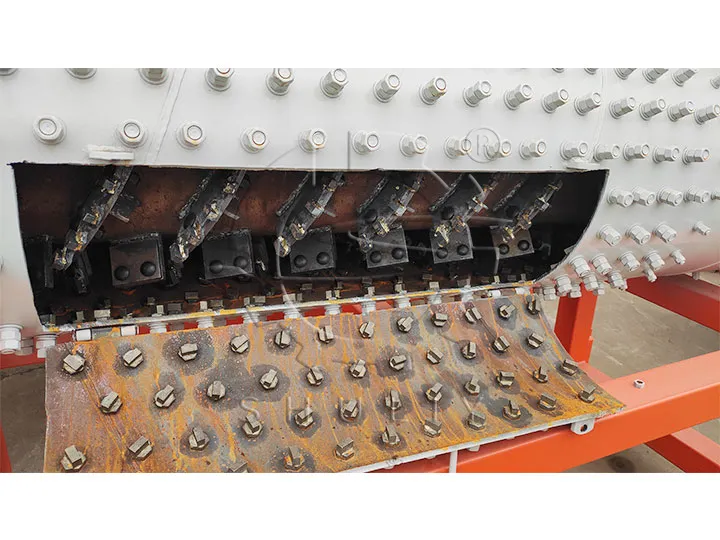

- Use of carbide blades: The use of carbide blades ensures strong wear resistance and high cutting precision of the blades, prolonging the service life of the equipment and reducing maintenance costs.

- High de-labeling rate: The machine’s design and technology allow for a high de-labeling rate, ensuring that the majority of labels are effectively removed, thus improving the efficiency and effectiveness of the subsequent recycling process.

PET Bottle Label Remover Working Video

Let’s look at the application of label removing machines in PET bottle recycling.

Structure And Working Principle

After watching the video, let’s find out how it works.

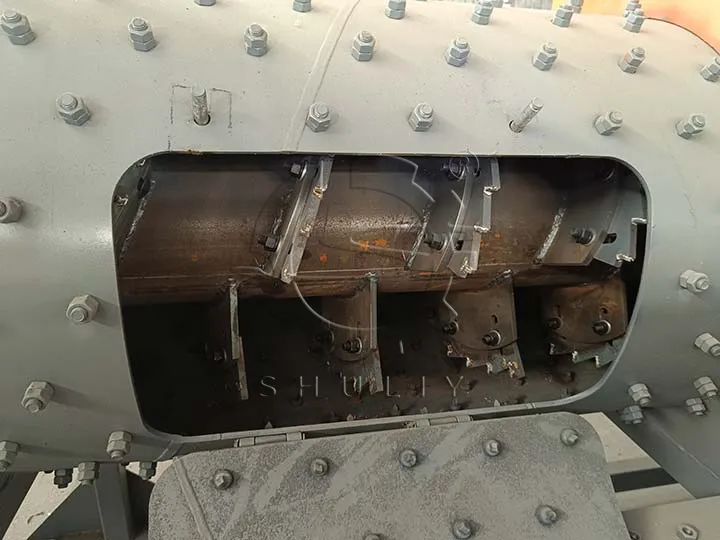

The main parts of the PET bottle label remover include the main shaft, the movable knife on the main shaft, the fixed knife on the cylinder wall of the de-labeling machine, the frame, the fan, and so on.

When the PET bottle enters the machine, the sharp tungsten carbide blade makes a scratch on the label of the bottle, and the teeth on the blade peel off the label. The spindle then rotates with the screw, conveying the bottles to the outlet. The peeled label will be blown out by the fan, thus realizing the detachment of PET bottles and labels.

PET Bottle Label Remover Processing Effect

PET bottles without labels

Models And Specifications

- Brand: Shuliy Machinery

- Type: SL-600

- Capacity: 1-1.2t/h

- Applicable raw materials: PET bottles

- The rate of removing the label: is 98%

- Customization: Support customization

PET Bottle Recycling Machine Supplier

We are a professional PET bottle recycling machine supplier, dedicated to providing customers with high-quality equipment and excellent service. Our products include various models and specifications of PET bottle recycling equipment, which can meet the needs of different customers.

If you are interested in our PET bottle label remover machine or PET bottle recycling line, we welcome you to contact us at any time for more information about product specifications, performance features, and customization requirements. Our team will be happy to provide you with professional consulting services and offer you the most suitable solutions to meet your needs and requirements. Whether you are looking for a single piece of equipment or a complete recycling line of ancillary equipment, we will provide you with high-quality products and perfect after-sales service to ensure that you can get the maximum return on your investment.