PET Bottle Washing Plant Sent To Congo

Sharing the good news: we are pleased to announce that a customer from Congo has chosen our PET…

Sharing the good news: we are pleased to announce that a customer from Congo has chosen our PET bottle washing plant and it is now about to leave for their factory.

Providing Solutions

In our communication with the customer, we learned about their factory’s PET bottle recycling needs. The customer wants to process the waste PET bottles into clean bottle flakes. Based on the customer’s needs, we have customized a complete solution for PET bottle cleaning. The solution not only includes efficient cleaning equipment but also covers installation and after-sales service to ensure that the customer can make full use of our PET bottle washing plant and achieve optimal production efficiency.

PET Bottle Washing Plant specifications

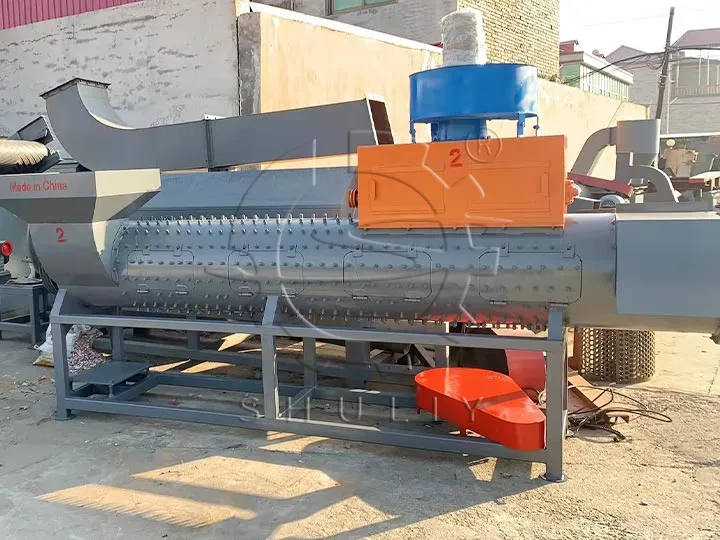

PET Label Remover Machine

- Remove the label from the bottle

- Power: 11kw+2.2kw

- Size:4000*1000*1600mm

- Weight: 2600kg

- Crush the bottle into small chips

- Power: 11kw

- Capacity: 300kg/h

- Size: 1300*650*800mm

Plastic Float Sink Tank

- Separate PET chips and PE bottle cap

- Power: 3kw

- Size: 5000*1000*1200mm

PET Friction Washing Machine

- Friction washing PET bottle flakes

- Power: 5.5kw

PET Flakes Dryer Machine

- Dewatering for PET chips

- Power: 7.5kw

- Size: 1300*600*1750mm

PET Bottle Washing Line Manufacturer

As a professional PET bottle washing line manufacturer, we are committed to providing customers with customized solutions to meet their specific needs and requirements. If you are considering purchasing this equipment, please feel free to contact us for consultation.