Plastic Crusher Wearing Parts Maintenance

In the long-term use of the plastic crusher, the maintenance and replacement of wearing parts is the key…

In the long-term use of the plastic crusher, the maintenance and replacement of wearing parts is the key to ensuring that the equipment continues to operate efficiently. Understanding and timely handling of worn parts is essential to extend equipment life and reduce maintenance costs.

The Importance of Maintaining Wear Parts

The state of wearing parts is directly related to the performance and stability of the plastic recycling shredder machine, so the maintenance and management of wearing parts are crucial. Timely maintenance can reduce downtime, reduce maintenance costs, extend the service life of the equipment, and improve production efficiency.

Types Of Wearing Parts And Maintenance

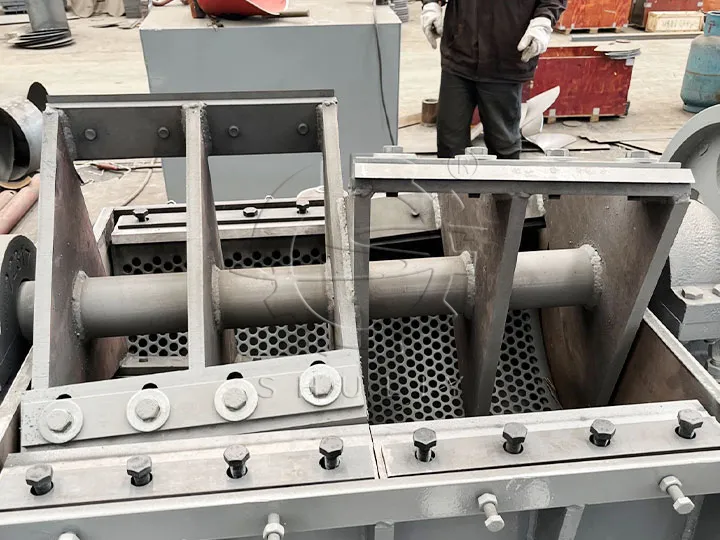

In the plastic crusher, common wearing parts include blades, bearings, screens, motors, and so on. Regular inspection and maintenance of these wearing parts can effectively reduce the failure caused by wear and tear, and ensure the normal operation of the equipment.

Blades

Blades are one of the most critical wearing parts in plastic scrap shredder. They are directly involved in the crushing process of waste plastics, so their wear and tear directly affects the crushing efficiency and quality. Regularly checking the degree of wear and tear of the blades, and timely replacement of badly worn blades can ensure the normal operation of the equipment and efficient production.

Sieve

Sieves play an important role in filtering and controlling particle size in plastic crushers. With time, the screen mesh may be damaged due to excessive force or clogging. Regular inspection and cleaning of the screen mesh and timely replacement of aged or damaged screen mesh can ensure that the crushed plastic particles meet the requirements and improve the reuse rate of waste plastics.

Bearing (Mechanical)

Bearing is an important component to support the normal operation of the plastic crusher, which is prone to wear and damage after a long time of use. Regularly filling the bearings with lubricant and keeping the bearings lubricated can prolong the service life of the bearings and ensure the stable operation of the equipment.

Motors and Drive Systems

The motor and transmission system is the power source of the plastic recycling shredder machine, which may be damaged by wear and tear, overheating, or other reasons after a long time of use, and need to be repaired or replaced.

Summary: Regular Maintenance Of Plastic Crusher

The vulnerable parts of the plastic scrap shredder are the key to the long-term stable operation of the equipment, and also an important guarantee for ensuring production efficiency and product quality. Regular inspections and timely replacement of vulnerable parts can effectively reduce the failure rate of equipment and extend its service life.