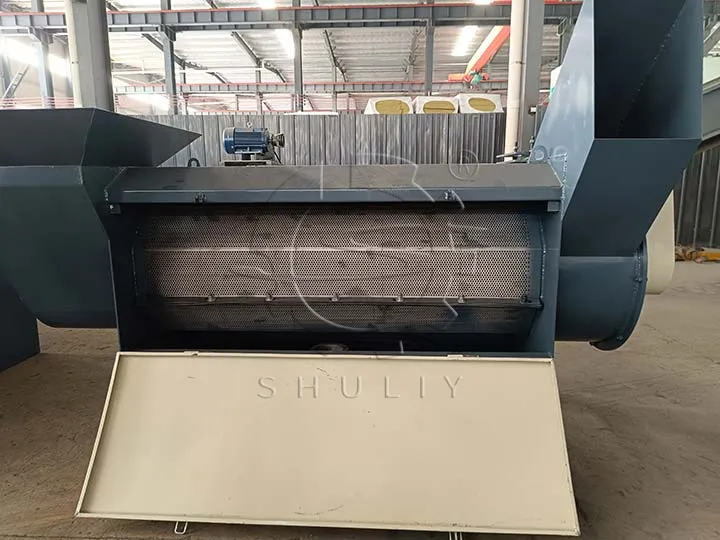

Plastic Dewatering Machine

The plastic dewatering machine is mainly used to completely remove the water remaining in the plastic after washing and improve the dryness of the plastic, to reduce the time and cost of subsequent processing.

The plastic dewatering machine is an efficient plastic dewatering machine designed for cleaning PP PE PET PVC and other sheet materials. It discharges the water on the surface of the plastic by centrifugal force through high-speed rotation to ensure that the material reaches the required dryness in the subsequent processing.

Our centrifugal dryer dewatering machine is characterized by strong processing capacity, good dewatering effect, high applicability, etc. It is an important link in the plastic recycling production line and can be customized and configured according to different output requirements to meet the production requirements of various scales.

Video Of Horizontal Dryer In Action

Plastic Dewatering Machine Introduction

A horizontal dryer for plastic chips is mainly used to completely remove the water remaining in the plastic after washing and improve the dryness of the plastic, to reduce the time and cost of subsequent processing. The machine is suitable for all kinds of plastic materials, including PET, HDPE, LDPE, LLDPE, PP, PVC, ABS, etc. It is widely used in plastic bottle recycling and plastic sheet recycling.

Advantages of Plastic Flake Dewatering Machine

- High drying rate: the equipment can control the moisture on the surface of the plastic within 3%-5%. If even lower moisture content is required, a drying pipe can be added to the rear end of the equipment to further reduce the moisture to 0.5%-1%.

- Wide applicability: Whether it is a soft or hard material, the plastic dewatering machine can dewater efficiently and ensure that the material reaches the ideal dryness in the subsequent processing.

- Highly customizable: the equipment can be tailored to the specific needs and production scale of the customer to ensure its optimal performance in various application scenarios.

Working Principle Of Plastic Chips Dryer Machine

The working principle of the plastic dewatering machine is based on the principle of centrifugal force dewatering. The plastic material enters the machine into a horizontally placed perforated drum. The drum rotates at high speed driven by a motor, generating a strong centrifugal force, which throws out the water on the surface of the plastic through the holes. The dewatered material is then discharged through the discharge port and into the next process.

Application Of Horizontal Dryer

Plastic dewatering machine is widely used in various plastic recycling production lines such as PET bottle washing lines, especially after plastic crushing and washing, for efficient dewatering of cleaned plastic materials.

Whether it is soft materials such as film, or hard materials such as bottles and granules, a plastic flake dewatering machine can effectively remove water through the principle of centrifugal dewatering to ensure the smoothness of the subsequent processing link.

Its application covers a wide range of plastic types such as PE, PP, PET, etc. It is suitable for the production process of recycled plastic granules and is an important equipment to enhance the efficiency of plastic recycling.

Parameters of Plastic Dewatering Machine

- Model: SL-550

- Capacity: 1000kg/h

- Drying rate: 95%-98%

- Outer diameter: 550mm

- Length: 1000mm

- Filter hole diameter: 4mm

- Drying Pipes: Moisture control to 0.5% – 1%

Role Of The Plastic Dryer Machine

Plastic dryer machines have a variety of important roles in the plastic recycling and pelletizing process:

- Efficient Dewatering: Rapidly removes water from the surface of cleaned plastics to ensure that they are dry.

- Improve the quality of granulation: dry plastic is not easy to produce bubbles and defects in the granulation process, to ensure the purity and quality of granules.

- Increased productivity: Dry plastic materials are easier to process for subsequent processing, such as pelletizing, extrusion, or injection molding.