Máquina trituradora de garrafas PET

A máquina trituradora de garrafas PET é um equipamento especializado para triturar resíduos de garrafas PET em pedaços. Este artigo é uma introdução detalhada à máquina, incluindo seu princípio de funcionamento, estrutura, especificações, preço e assim por diante.

A máquina trituradora de garrafas PET é um equipamento projetado especificamente para triturar e processar garrafas PET descartadas, um tipo comum de garrafa plástica usada para embalar bebidas, alimentos e outros produtos líquidos. Uma máquina trituradora de PET corta garrafas PET descartadas em pequenos pedaços ou cacos por meio de força mecânica, tornando-as mais fáceis de limpar e reprocessar posteriormente.

Nossa retificadora de garrafas é feita de aço de alta qualidade, com lâminas afiadas e duráveis e estrutura robusta, que pode funcionar de forma estável por um longo tempo. Seu design foca na fácil operação e manutenção, garantindo que os usuários possam usar e manter o equipamento com facilidade.

Características da nossa máquina trituradora de garrafas

- Material da lâmina: Feito de 9CrSi durável para desempenho duradouro.

- Malha de tela ajustável: O tamanho da malha é de 16 a 18 mm, personalizável para diferentes necessidades.

- Personalização: Disponível para atender requisitos específicos de processamento.

- Vários modelos: Oferece uma variedade de modelos para acomodar diferentes capacidades de produção.

Matérias-primas e produtos acabados

A matéria-prima para as máquinas trituradoras de garrafas PET são resíduos de garrafas PET, que podem ser garrafas vazias de diversos produtos de consumo, como bebidas, alimentos, detergentes, etc. As garrafas PET geralmente têm aparência transparente, semitransparente ou colorida, e são coletadas e classificados antes de serem alimentados na máquina trituradora de PET para processamento.

O produto acabado da máquina trituradora de garrafas são chips de plástico PET, os chips de plástico PET geralmente têm formatos e tamanhos irregulares, são processados pelo triturador e podem ser usados para reciclagem, como matéria-prima para a fabricação de novas garrafas PET, têxteis, materiais de construção e assim por diante.

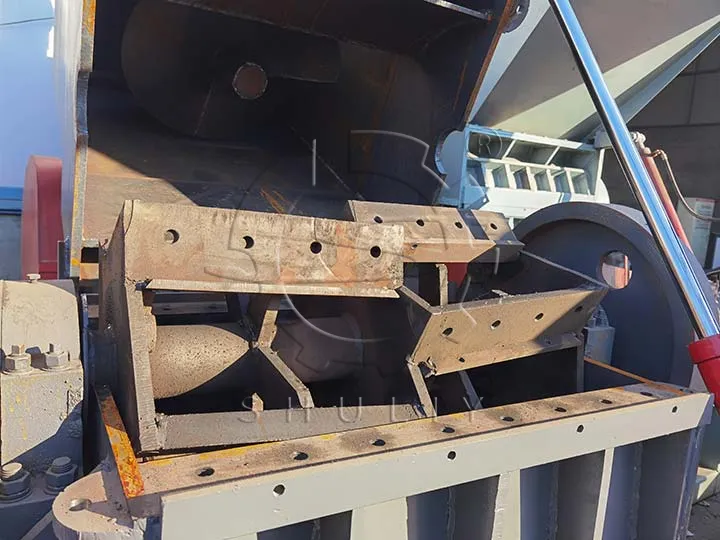

Estrutura da máquina trituradora de garrafas PET

A máquina trituradora PET geralmente consiste em componentes principais, como entrada de alimentação, ferramenta de corte, rotor, tela, redutor, motor, porta de descarga e corpo. Esses componentes trabalham juntos para permitir que garrafas PET descartadas sejam processadas por meio de corte, trituração e peneiramento, transformando-as em fragmentos de plástico PET renováveis.

Como funciona o triturador de garrafas PET?

A máquina trituradora de sucata de garrafas PET utiliza força mecânica para cortar e esmagar resíduos de garrafas PET em pequenos pedaços ou fragmentos. Seu processo de trabalho geralmente inclui as seguintes etapas:

- Alimentação: As garrafas PET usadas são colocadas dentro da máquina trituradora de garrafas plásticas através da abertura de alimentação. Essas garrafas podem ser pré-tratadas, como remoção de rótulos, tampas e outros detritos, para melhor trituração posterior.

- Trituração: Após a entrada da garrafa PET na máquina, o rotor começa a girar, acionando as facas montadas nela para realizar operações de corte e trituração. As facas giram em alta velocidade e cortam as garrafas PET em pequenos pedaços ou fragmentos.

- Peneiramento: Os chips de PET triturados passam por uma peneira, que serve para garantir que apenas os chips de plástico PET do tamanho certo passem.

- Descarga: Os flocos de garrafas PET peneirados são descarregados da máquina trituradora de garrafas PET através da saída ou na próxima etapa de reciclagem.

Vídeo de funcionamento da máquina trituradora PET

Especificações da máquina trituradora de garrafas de plástico

Aqui estão as informações de especificação de vários modelos quentes de máquinas trituradoras de garrafas PET para sua referência. Nossas máquinas podem ser personalizadas de acordo com os requisitos do cliente, como tamanho da tela, aparência da máquina e assim por diante.

| Modelo | SL-60 | SL-80 | SL-100 |

| Capacidade (kg/h) | 500 | 1000 | 1500 |

| Motor (kW) | 22 | 37 | 75 |

| Altura (m) | 1.8 | 2.6 | 2.6 |

| Espessura da faca (mm) | 30 | 40 | 40 |

| Espessura da placa (mm) | 16 | 20 | 30 |

Como fazer a manutenção da máquina trituradora PET?

Para garantir a operação estável a longo prazo e o trabalho eficiente da máquina trituradora de garrafas PET, são necessários manutenção e reparos regulares. Aqui estão algumas maneiras comuns de manter uma máquina trituradora de garrafas:

- Mantenha-a limpa: Limpe regularmente todas as peças da trituradora PET, principalmente as peças que tendem a acumular detritos, como facas, telas e portas de alimentação. Manter a máquina limpa por dentro e por fora ajudará a evitar o acúmulo de detritos e a manter o bom funcionamento dos componentes.

- Lubrificação regular: Para peças que precisam ser lubrificadas, como rolamentos de rotor, redutor, etc., adicione regularmente a quantidade certa de lubrificante ou graxa para reduzir o atrito e o desgaste e prolongar a vida útil das peças.

- Verifique e aperte os parafusos: Verifique regularmente as diversas peças de conexão e parafusos da trituradora de garrafas PET para certificar-se de que estão bem apertados para evitar afrouxamentos ou desprendimentos que podem causar instabilidade ou danos à máquina.

- Substituição regular de peças desgastadas: Verifique regularmente as facas, telas e outras peças que são fáceis de usar e substitua-as a tempo assim que estiverem desgastadas ou danificadas, para garantir o funcionamento normal da máquina e a eficiência da britagem .

Preço da máquina trituradora de garrafas de plástico

Ao considerar o preço da máquina trituradora de garrafas de plástico, vários fatores entram em jogo. Isso pode incluir a capacidade da máquina, os recursos, a reputação da marca e a demanda do mercado. Geralmente, os preços podem variar de algumas centenas a vários milhares de dólares, dependendo do modelo e das especificações.

Oferecemos uma vasta gama de trituradoras de garrafas plásticas, bem como soluções completas de reciclagem de garrafas PET a preços que variam de acordo com as especificações e características do equipamento. Estamos empenhados em fornecer produtos de alta qualidade para atender às necessidades dos nossos clientes e oferecer-lhes preços competitivos. Esforçamo-nos para fornecer aos nossos clientes as melhores soluções de qualidade, independentemente do tamanho do seu orçamento.