Fábrica de Fabricação de Bandejas de Ovos

A fábrica de produção de bandejas de ovos é um sistema de equipamentos utilizado para processar papel reciclado em polpa moldada…

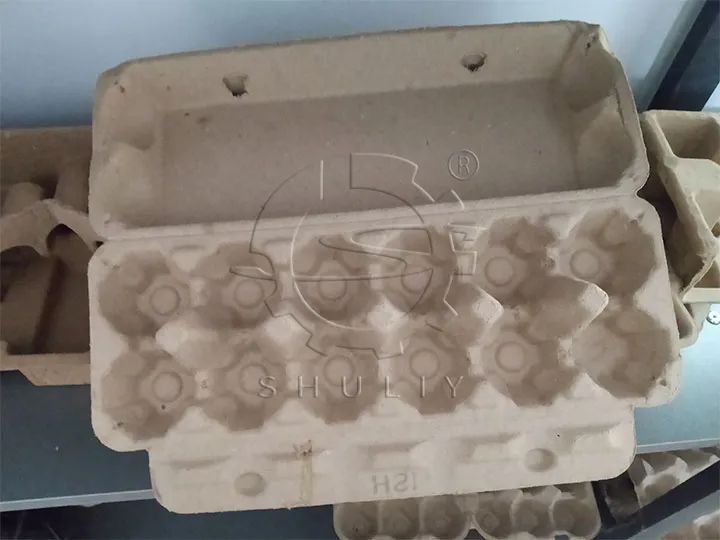

A fábrica de fabricação de bandejas de ovos é um sistema de equipamentos utilizado para processar papel reciclado em produtos de polpa moldada, como bandejas de ovos, bandejas de frutas e suportes para copos de café. A linha completa normalmente inclui seções de polpação, moldagem, secagem, prensagem a quente opcional e embalagem. Ao trocar os moldes, pode produzir bandejas de papel de vários tamanhos e aplicações. Este equipamento é amplamente utilizado na avicultura, embalagem de alimentos e transporte de produtos agrícolas.

Como um fornecedor experiente de máquinas para bandejas de ovos, oferecemos soluções de produção abrangentes e personalizadas adaptadas às necessidades dos nossos clientes. Desde a seleção de equipamentos até a instalação e formação, fornecemos um serviço completo para garantir uma operação suave e uma produção eficiente. As nossas máquinas são exportadas para todo o mundo e são bem recebidas pelos clientes.

Matérias-primas da linha de produção de bandejas de ovos

As matérias-primas para a fábrica de produção de bandejas de ovos são principalmente vários tipos de papel reciclado. Estes são processados em polpa através de hidropulpagem e mistura, depois moldados e secos usando moldes para produzir bandejas de ovos e outros produtos moldados em polpa. As matérias-primas comumente utilizadas incluem:

- Caixas de papelão ondulado usadas

- Jornais em papel de desperdício

- Papel de livro em desperdício

- Retalhos de papel

- Placas de polpa semi-acabadas

Tipos de Produtos Acabados

A nossa máquina de fabricação de bandejas para ovos pode produzir não apenas bandejas comuns para ovos, mas também uma variedade de produtos moldados em polpa, como bandejas para frutas, suportes para copos, bandejas para sapatos e bandejas para embalagens de produtos eletrônicos, simplesmente trocando os moldes. O equipamento é altamente adaptável, atendendo a diferentes necessidades de embalagem e ajudando os clientes a expandir seu mercado.

Quais máquinas estão incluídas em uma fábrica de produção de bandejas de ovos?

Uma fábrica completa de produção de bandejas de ovos normalmente inclui:

| Seção | Equipamento Principal | Função |

| Desagregação | Máquina de Pulper de Papel | Transforma papel reciclado em polpa |

| Formação | Máquina de Moldagem de Bandejas de Ovos | Forma a bandeja de ovos usando sucção a vácuo |

| Secagem | Secador de Metal / Forno de Tijolos / Secagem Natural | Seca rapidamente as bandejas molhadas para maior produção |

| Embalagem | Empilhador, Máquina de Embalagem de Bandejas de Ovos | Economiza trabalho e facilita o transporte |

Além disso, os clientes podem optar por moldar e embeber a bandeja de ovos usando uma prensa térmica, tornando o produto final mais esteticamente agradável e durável.

Vídeo de todo o processo de fabricação de bandejas de ovos

Por que os Clientes Escolhem Nossas Máquinas de Bandejas de Ovos?

- Baixo Custo: Utiliza papel reciclado como matéria-prima, fácil de coletar e econômico.

- Alta ProduçãoProduz de forma eficiente 1.000 a 8.000 pratos de ovos por hora.

- Mercado Amplo: As bandejas de ovos têm amplas aplicações e forte potencial de vendas.

- Serviço de Moldes Personalizados: Bandejas de ovos, bandejas de frutas, suportes para copos—moldes personalizados disponíveis.

- Apoio à Instalação no Local: Orientação online ou envio de engenheiro para montagem no exterior.

Parâmetros da fábrica de fabricação de bandejas de ovos

| Modelo | Capacidade | consumo de papel | Consumo de água |

| SL-3*1 | 1000-1500pcs/h | 120kg/h | 300kg/h |

| SL-4*1 | 1500-2000PCS/h | 160kg/h | 380kg/h |

| SL-3*4 | 2000-2500pcs/h | 200kg/h | 450kg/h |

| SL-4*4 | 3000-3500pcs/h | 280kg/h | 560kg/h |

| SL-4*8 | 4000pcs/h | 320kg/h | 600kg/h |

| SL-5*8 | 5000pcs/h | 400kg/h | 750kg/h |

| SL-5*12 | 6000pcs/h | 480kg/h | 900kg/h |

| SL-6*12 | 8000pcs/h | 640kg/h | 1040kg/h |

Oferecemos uma ampla gama de modelos de máquinas para bandejas de ovos e podemos recomendar a configuração de equipamento mais adequada com base nas suas necessidades, garantindo capacidade de produção compatível, layout eficiente e investimento rentável. Sinta-se à vontade para nos deixar uma mensagem no nosso site.

Pronto para começar? Obtenha sua cotação e proposta agora!

Se você está procurando uma fábrica de fabricação de bandejas de ovos adequada para o seu mercado local, sinta-se à vontade para nos contatar para especificações detalhadas, estimativas de investimento do projeto e desenhos de layout da fábrica. Nós forneceremos soluções personalizadas e suporte técnico abrangente.