Dry Ice Blocks Production Line

Dry ice blocks production line is a complete system designed for the continuous production, forming, conveying, packaging, and…

Dry ice blocks production line is a complete system designed for the continuous production, forming, conveying, packaging, and storage of dry ice blocks. It is widely used by companies that require stable dry ice supply for cold chain logistics, food processing, pharmaceutical transportation, industrial cleaning, and laboratory applications.

This production line integrates multiple core machines into one coordinated process, helping users improve production efficiency, reduce manual handling, and ensure consistent dry ice block quality.

What Is a Dry Ice Blocks Production Line

The dry ice manufacturing plant is an automated or semi-automated system that converts liquid CO₂ into solid dry ice blocks. The process typically includes dry ice pelletizing, block pressing, conveying, packaging, and insulated storage.

Compared with single dry ice machines, a complete production line is more suitable for customers with medium to large output requirements, long-term operation plans, and commercial dry ice distribution needs.

Working Video of The Dry Ice Manufacturing Plant

Main Equipment in the Dry Ice Blocks Production Line

Dry Ice Pellet Machine

The dry ice pellet making machine is the first step of the production process. It converts liquid carbon dioxide into dry ice pellets by rapid expansion and cooling.

These pellets serve as the raw material for block pressing, ensuring uniform density and stable block quality. The output capacity of the pellet machine can be selected based on the target production volume.

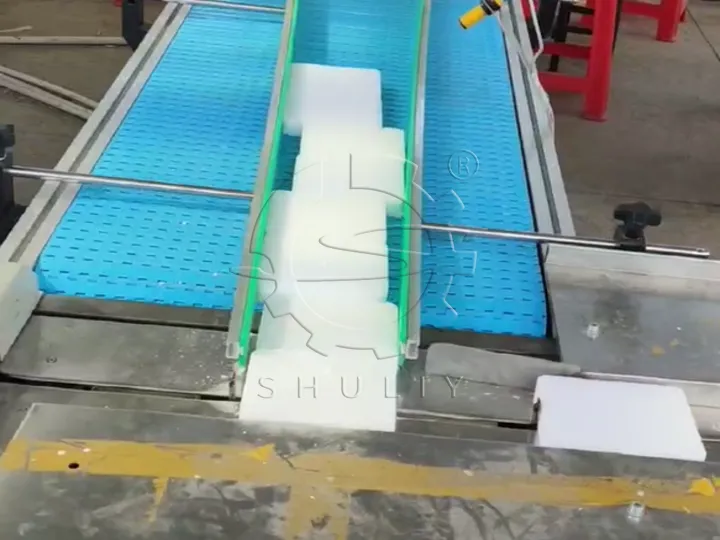

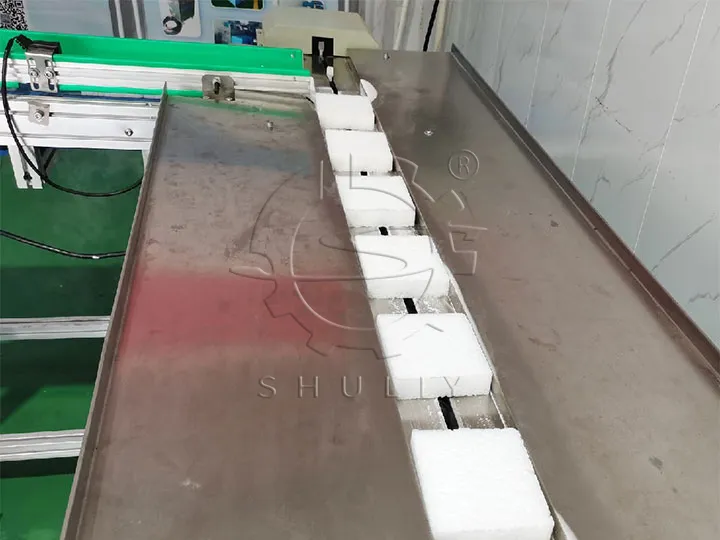

Dry Ice Block Press Machine

The dry ice block maker compresses dry ice pellets into solid blocks with fixed dimensions and weight.

Block size, density, and pressing pressure can be adjusted according to application needs, such as long-distance transportation or extended storage. This step directly affects sublimation rate and handling efficiency.

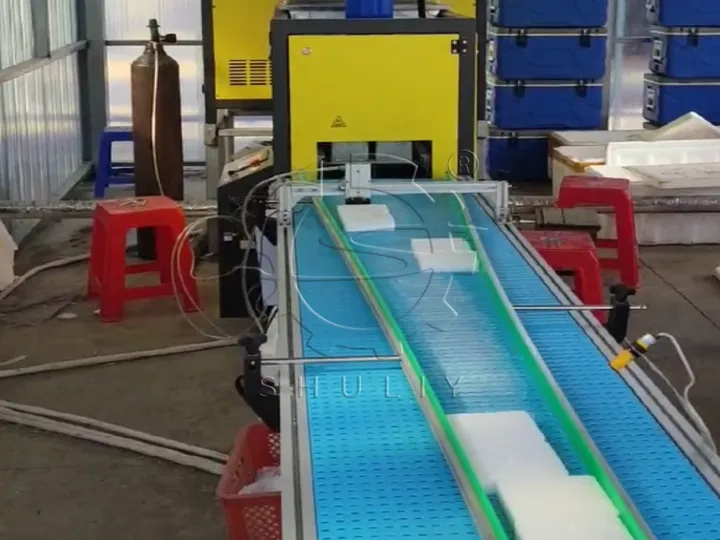

Conveying System

The conveying system transfers dry ice blocks from the press machine to the packaging section.

It reduces manual contact with dry ice, improves operational safety, and maintains continuous workflow. Conveyor layouts can be customized based on factory space and line configuration.

Dry Ice Packaging System

The packaging system wraps dry ice blocks using suitable packaging materials to slow down sublimation and make transportation easier.

Different packaging solutions can be applied depending on customer requirements, including manual-assisted or automated packaging options.

Insulated Storage Boxes for Dry Ice Blocks

After packaging, dry ice blocks are placed into insulated storage boxes.

These boxes are designed to reduce CO₂ sublimation loss during short-term storage and logistics preparation. Proper insulation helps maintain product quality before delivery or internal use.

Applications of Dry Ice Blocks Production Line

A dry ice blocks production line is suitable for various industries, including:

- Cold chain transportation and logistics

- Food and seafood preservation

- Pharmaceutical and medical transport

- Industrial cleaning and maintenance

- Laboratories and research institutions

Different industries may require different block sizes and output capacities, which can be addressed through flexible line configuration.

Advantages of Using a Complete Production Line

- Continuous and stable dry ice production

- Reduced labor intensity and manual handling

- Consistent block size and density

- Scalable capacity for growing business needs

- Better integration with packaging and storage processes

Better integration with packaging and storage processes

These advantages make the dry ice blocks production line suitable for commercial and industrial dry ice suppliers.

Customization and Line Configuration

Each dry ice manufacturing plant can be configured based on:

- Required production capacity

- Dry ice block size and weight

- Automation level

- Factory layout and available space

By selecting appropriate machine models and system layouts, users can build a production line that fits their actual operating needs.

Contact Us for More Dry Ice Blocks Production Line Details

A well-designed dry ice blocks production line provides an efficient and reliable solution for industrial dry ice manufacturing. By integrating pellet production, block pressing, conveying, packaging, and insulated storage, the line supports stable output and practical operation for long-term use.

If you are planning to invest in dry ice block production or upgrade existing equipment, a complete production line is a practical option to consider. You can contact us to discuss your material requirements, expected capacity, and system configuration, and we will help you select a suitable solution.