Scrap Metal Shredder

Facing bulky, hard-to-handle metal scrap? Our industrial scrap metal shredders provide the solution. Engineered with high-torque cutting shafts…

Facing bulky, hard-to-handle metal scrap? Our industrial scrap metal shredders provide the solution. Engineered with high-torque cutting shafts and the option for external screens, we offer the specific technology to reduce your volume, control your output size, and increase the value of your scrap. Let us match you with a model that fits your material and capacity goals.

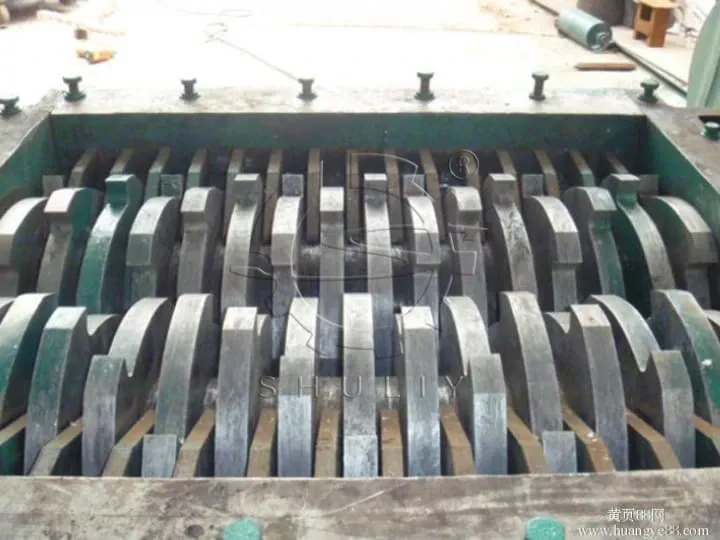

How Our Dual-Shaft Metal Shredder Works

The core of our industrial metal shredder is its two counter-rotating shafts equipped with durable cutting discs. These shafts rotate at low speeds but generate high torque, providing immense shearing and tearing force.

- Feeding and Pre-compression: Material is fed into a large hopper. The geometry of the hopper and the initial action of the shafts help to pre-compress and grip the bulky scrap.

- Shearing and Tearing: As the material is drawn between the rotating shafts, the interlocking cutting discs effectively shear, tear, and rip it apart into smaller, more manageable pieces.

- Controlled Discharge: The shredded material passes through the bottom of the scrap metal shredder. A key feature is the option to add an external circular screen (sieve) to control the final output size. Particles smaller than the screen mesh fall through, while larger pieces are carried back to the cutting chamber for further reduction.

Working Video of Our Double Shaft Shredder Machine

Key Features and Technical Advantages

Our dual-shaft shredders are engineered for performance and longevity. Here are the aspects that set them apart:

High Torque, Low Speed Design: This principle minimizes energy consumption, reduces noise levels, and prevents unnecessary wear, making the operation both economical and reliable.

Robust Welded Body: The main frame is constructed from heavy-duty steel plates, ensuring structural integrity and stability even under the most demanding conditions.

Advanced Control System: The scrap metal shredder comes with a user-friendly PLC control system, allowing for easy operation, monitoring, and protection against overloads and jams.

Modular Screen for Size Control: The optional external circular screen is a critical feature, giving operators direct control over the final product size, which is essential for meeting specific market requirements.

Multiple Models Available: We offer a range of models with varying power, throughput, and inlet sizes to match your specific capacity and material processing needs.

Versatile Applications: What Materials Can Be Shredded?

While the primary design is for metal, the versatility of our dual-shaft scrap metal shredders is a significant advantage. They are capable of processing a wide array of materials, making them a valuable asset for various recycling operations.

Metals:

- Scrap Cars and Car Shells: Efficiently reduce entire car bodies and frames into fist-sized or smaller fragments for easy melting.

- Old Appliances: Refrigerators, washing machines, air conditioners, etc.

- Steel Drums and Containers: Quickly process used industrial drums.

- Non-Ferrous Metals: Such as aluminum cans, copper wire, and radiators.

- Manufacturing Scrap: Including turnings, borings, and rejected metal parts.

- E-Waste: To recover valuable metals from computers and other electronic devices.

Other Materials for Scrap Metal Shredder

- Tires: For recycling crumb rubber.

- Plastics: Including hard plastics, plastic bottles, and woven bags.

- Wood, Paper, and Cardboard: For waste volume reduction or RDF production.

- MSW (Municipal Solid Waste): For pre-sorting and volume reduction.

Metal Shredder Parameter Description

To meet a diverse range of recycling demands, we offer a full series of double-shaft scrap metal shredders, with models covering a wide spectrum, including Model 400, 600, 800, 1000, 1200, up to heavy-duty models like 1600, 1800, and 2000. Each model varies in its core parameters; typically, a larger model number corresponds to a greater number of blades, more blade claws, and a higher processing capacity per hour. All of our shredder blades are forged from high-strength, wear-resistant 9CrSi alloy tool steel, ensuring long-lasting sharpness and durability when processing complex metal materials.

We understand that no two clients’ needs are exactly alike. Therefore, our team of experts will first thoroughly understand the type of material you plan to process (such as scrap cars, color steel tiles, paint buckets, etc.), the material’s thickness, and your specific requirements for output size and capacity. Based on this, we will recommend the most suitable and cost-effective machine model for your operation.

Furthermore, we provide professional customization services. We can optimize the machine’s blade thickness, claw design, and even the entire power system according to your unique needs, ensuring that what you receive is not just a machine, but a complete solution perfectly tailored to your business.

Why Choose Our Scrap Metal Shredder?

Investing in our industrial shredder for metal translates into tangible operational benefits:

- Increased Efficiency: Dramatically reduces the volume of waste, lowering transportation and handling costs.

- Enhanced Material Value: Shredded, homogeneous material is cleaner and commands a higher price from smelters and recyclers.

- Space Optimization: Shredded scrap is denser, freeing up valuable space in your yard.

- Downstream Readiness: The output is ideal for further processing in balers, separators, or granulators.

- Durability and Low Maintenance: Built to last with minimal downtime, ensuring a high return on your investment.

FAQs of Scrap Metal Shredder

1, What types of materials can this dual-shaft shredder process?

A: Our dual-shaft shredder is incredibly versatile and can handle a wide range of waste materials. The main categories include: scrap metal, waste plastics, scrap tires, other waste.

2, Is a diesel-powered option available?

A: Yes, we offer full customization. Our standard configuration is an electric motor drive. However, if your facility has an unstable power supply or you need to operate in a location without a fixed power source, we can customize the shredder with a diesel generator set to ensure efficient operation in any environment.

3, How do I choose the right shredder model for my needs?

A: Selecting the most suitable model depends on three key factors: material type and size, required capacity, output size.

4, Do you offer after-sales service and a warranty?

One-Year Warranty: We offer free replacement for any core components that experience quality issues during the warranty period.

Technical Support: We provide remote online installation guidance and operational training. For large-scale production lines, we can also dispatch our engineers to your site for installation and commissioning.

Spare Parts Supply: We guarantee a long-term supply of all wearing parts and spare parts to ensure your production continues without interruption.

Explore Other Metal Processing Solutions

A dual-shaft scrap metal shredder is the ideal choice for breaking down materials and reducing their volume. However, in practical metal recycling operations, different processing goals often require different types of equipment. As a professional manufacturer of recycling machinery, Shuliy also offers other high-efficiency metal processing solutions to meet your diverse needs.

- If you are dealing with light, bulky scrap metal (such as sheet metal, metal shavings, or aluminum cans) and want to maximize savings on storage space and transportation costs, our metal baler is the perfect solution. It uses high pressure to compact scrap into dense, uniformly sized bales, making them much easier to stack, transport, and melt.

- For oversized and heavy-duty scrap steel (like rebar, H-beams, large pipes, or vehicle chassis) that may be difficult to shred directly, a gantry shear demonstrates its immense power. Acting like a giant pair of scissors, it easily and efficiently cuts these heavy materials into smaller, more manageable pieces suitable for further processing or furnace feeding.

Double Shaft Shredder Manufacturer

A reliable scrap metal shredder is no longer a luxury but a necessity for a modern, profitable recycling operation. Our dual-shaft shredders are engineered to be the workhorse of your facility, handling the toughest materials with unwavering reliability. From ferrous and non-ferrous metals to tires and plastics, our machines deliver consistent performance, controlled output, and long-term value.

We invite you to contact our technical experts to discuss your specific requirements. Let us help you select the perfect scrap metal shredder model to optimize your recycling process and boost your profitability.