Waste Tire Block Cutter

Our waste tire block cutter is a vital component in the semi-automatic tire recycling production line. Positioned directly…

Our waste tire block cutter is a vital component in the semi-automatic tire recycling production line. Positioned directly after the tire strip cutter, it is specifically designed to efficiently cut long rubber strips into uniformly sized blocks. By providing standardized, easy-to-process feedstock for the subsequent rubber cracker mill, our block cutter not only significantly boosts the entire line’s output and efficiency but also effectively protects the mill’s rollers from damage. It is a reliable guarantee for achieving stable, high-yield production of quality rubber powder or granules.

Functions of Tire Block Cutter

After a scrap tire has been processed by the sidewall and strip cutters, the material is still in the form of long rubber strips. Feeding these long strips directly into a rubber crusher is impractical and can lead to feeding difficulties, low efficiency, and even equipment jams. This is where the waste tire block cutter excels:

- Standardizes Feedstock: It cuts the long strips into uniform blocks of approximately 3-5 cm, which is the ideal infeed size for a rubber cracker mill.

- Boosts Grinding Efficiency: Uniform blocks feed smoothly into the rubber powder mill’s rollers, allowing for continuous and efficient grinding, thereby increasing the final output of rubber powder.

- Protects Core Equipment: It prevents issues like strip entanglement or irregular feeding that can cause impact and wear on the cracker mill’s rollers, extending the service life of your core equipment.

Working Principle of the Waste Tire Block Cutter

- Feeding: The operator feeds the long rubber strips from the strip cutter into the infeed chute of the block cutter.

- Shearing: Inside the machine, a set of moving blades (or sword knives) driven by a motor works in tandem with a fixed blade. The high-speed rotation of the moving blades creates immense shearing force against the fixed blade, rapidly cutting the rubber strip into small blocks.

- Precision Wire Cutting: A key technical detail is the clearance between the moving and fixed blades. We recommend this gap is precisely maintained at approximately 0.1 mm. This precision setup ensures that as the rubber is cut, any fine steel wires remaining inside are also effectively severed, preparing the material for downstream magnetic separation.

- Discharging: The cut rubber blocks are discharged from the outlet and can be conveyed directly to the rubber cracker mill via a conveyor belt.

Tire Block Cutting Machine Video

Key Advantages & Features of Waste Tire Block Cutter

- Produces Uniform Blocks: Ensures a stable and consistent feed for the subsequent grinding process, which is fundamental for high yield and efficiency.

- Durable Alloy Blades: The blades are forged from high-hardness, wear-resistant alloy steel for exceptional durability. After extended use, they can be re-sharpened multiple times, significantly reducing operating costs.

- Efficient and Energy-Saving: An optimized transmission and shearing design deliver powerful cutting force while maintaining low energy consumption.

- Two Models Available: We offer both a Standard and an Upgraded model, with capacities ranging from 800 kg/h to 1500 kg/h, allowing clients to choose based on their production scale.

Position in the Rubber Powder Production Line

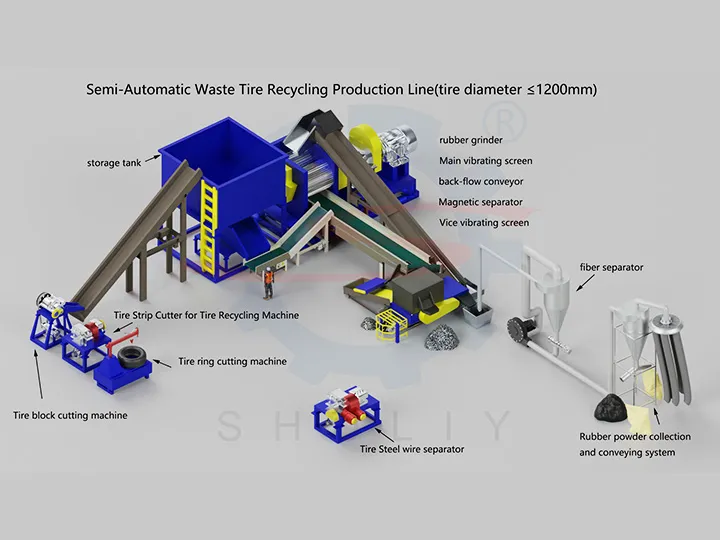

In the semi-automatic rubber powder production line, waste tires first pass through the tyre bead cutting machine to remove the bead wire, then the tire strip cutter cuts the tires into long strips, which are subsequently fed into the block cutter.

The waste tire block cutter further processes the strips into uniform small pieces, making them easier for the steel wire separator and rubber powder mill to handle.

As a key link in the process, the tire block cutting machine plays a crucial role by improving material size consistency and providing a stable feedstock for subsequent steel separation and fine grinding, thereby ensuring the continuity and efficiency of the entire tire recycling line.

Waste Tire Block Cutter Technical Specifications

We offer two main waste tire block cutter models to meet different production capacity needs.

| Item | QKJ-358 Standard Model | Upgraded Model |

| Motor Power | 5.5KW | 18.5KW |

| Capacity | 800 kg/h | 1500 kg/h |

| Output Size | Approx. 3 x 5 x 6 cm | Approx. 5 x 5 cm |

| Dimensions (LWH) | 1.0 x 0.8 x 1.4 cm | 1.3 x 1.1 x 1.5 cm |

| Weight | 800 kg | 1200 kg |

Contact Us to Complete Your Tire Recycling Line

A high-performance waste tire block cutter is a key investment for the smooth operation, cost reduction, and efficiency improvement of your semi-automatic tire recycling line.

As a professional manufacturer in the recycling machinery field, we not only provide high-quality individual machines but can also design complete recycling solutions for you. Contact our technical experts today to configure your most efficient semi-automatic recycling line.