آلة تصنيع لب الورق

في خط إنتاج حوامل البيض، تعتبر آلة تصنيع لب الورق قطعة أساسية من المعدات.

في خط إنتاج صواني البيض، تعتبر آلة تصنيع لب الورق قطعة أساسية من المعدات. وظيفتها الرئيسية هي خلط وتحريك الورق المستعمل مع الماء لإنتاج لب متجانس وناعم، مما يوفر أساسًا قويًا لعملية التشكيل اللاحقة. تلعب عملية اللب الفعالة والمستقرة دورًا رئيسيًا في جودة وكفاءة إنتاج صواني البيض.

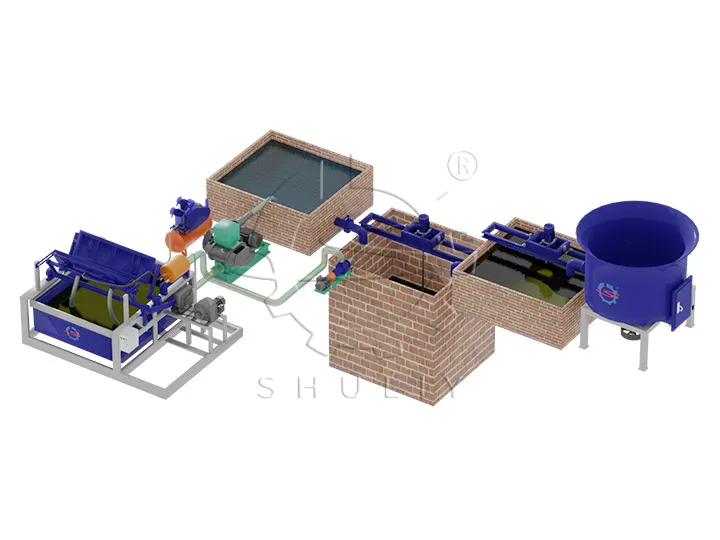

تقدم شولي نظام تصنيع لب سهل الاستخدام وكامل مصمم لتحسين جودة اللب وتبسيط التشغيل. يمكننا أيضًا تقديم رسومات تخطيطية مصممة حسب حجم مصنعك لتحقيق أفضل استخدام للمساحة.

ما هي آلة لب الخشب؟

آلة التقطيع، والمعروفة أيضًا باسم جهاز التقطيع، هي جهاز يستخدم لإعادة تدوير الورق. تستخدم آلية خلط عالية السرعة لخلط الورق المستعمل مع الماء، مما يفصل الألياف الورقية وينشرها بشكل متساوٍ لتشكيل لب مناسب للتشكيل. تُستخدم آلات التقطيع على نطاق واسع في آلات صناديق البيض، وتغليف صناديق الورق، وتشكيل اللب، وغيرها من المجالات ذات الصلة.

وظائف آلة الهيدرابولر

- تقطيع وتحطيم الورق المستعمل: تحويل الصحف القديمة، والكراتين، وغيرها من الورق المستعمل إلى لب ليفي.

- خلط اللب بشكل موحد: تحريك الورق والماء بالكامل لإنشاء لب بتركيز مناسب.

- ضمان جودة التشكيل: يؤثر تجانس اللب على السماكة، والقوة، وتناسق المظهر لحوامل البيض النهائية.

- توفير العمالة والوقت: يقلل التشغيل الآلي من العمل اليدوي ويحسن كفاءة تصنيع اللب.

سير عمل عملية اللب

- إطعام وإضافة الماءيتم إضافة الورق المستعمل ونسبة معينة من الماء إلى آلة تصنيع لب الورق.

- التحريك والتقطيعتبدأ الآلة، ويعمل نظام التحريك بسرعة عالية لتقطيع الورق إلى لب ليفي.

- تعديل قوام اللبتتدفق اللب إلى خزان خلط حيث يتم إضافة الماء أو إزالته لضبط التركيز المناسب للتشكيل.

- تسليم اللبيتم ضخ اللب المحضر بواسطة مضخة الإمداد إلى آلة تشكيل صواني البيض للخطوة الإنتاجية التالية.

كيفية تحسين جودة حوامل البيض أثناء عملية تصنيع اللب

في إنتاج صناديق البيض، تؤثر جودة اللب بشكل مباشر على القوة والمظهر والنعومة للمنتج النهائي. من خلال تحسين عملية اللب، يمكن تحسين الجودة العامة لصناديق البيض بشكل كبير. إليك بعض التوصيات الرئيسية:

1، اختيار مواد الورق المستعمل المناسبة

من الأسهل معالجة الورق المستعمل عالي الجودة، النظيف، الخالي من الزيت والبلاستيك بشكل متساوٍ، مما يساعد على تحسين الكثافة والصلابة لصواني البيض.

2، التحكم في تركيز اللب

الحفاظ على تركيز لب مناسب (عادةً 3%-5%) يساعد في ضمان امتصاص متساوٍ من قبل القالب، مما يقلل من المشكلات مثل عدم تناسق السماكة أو عدم اكتمال تشكيل الصينية.

3، تأكد من خلط اللب بشكل متساوٍ

يجب أن تعمل آلة تحضير لب الورق مع تحريك مستمر وعالي السرعة لتفريق ألياف الورق بالكامل. وهذا يخلق لبًا ناعمًا وموحدًا يحسن دقة التشكيل.

4، أضف الإضافات اللازمة

عند الحاجة، يمكن إدخال إضافات مثل عوامل مقاومة الماء، والأصباغ، أو معززات القوة لتحسين مقاومة الماء، والمظهر، أو القوة الهيكلية للصواني.

اتصل بنا لحلول إنتاج صواني البيض

إذا كنت تخطط لإنشاء مصنع لتصنيع صواني البيض، يمكننا توفير آلات لب الورق موثوقة مع دعم فني مخصص.

نرحب بكم للتواصل معنا للحصول على مزيد من المواصفات والمعايير وفيديو العمل والحلول المخصصة لمعدات اللب. سنقدم اقتراحات تكوين مناسبة وعروض أسعار وفقًا لاحتياجات الإنتاج الخاصة بكم وتخطيط المصنع.