Plastic Granule Cutter

The plastic granule cutter is used as an auxiliary machine, mainly in plastic granulation lines. Its main function is to cut long strips of plastic extruded from plastic scrap granulators into small pellets of uniform size. This article focuses on the role, application, and structure of the machine.

The plastic granule cutter is used as an auxiliary machine, mainly in plastic granulation lines. Its main function is to cut long strips of plastic extruded from plastic scrap granulators into small pellets of uniform size. These pellets are uniform in size and facilitate subsequent storage, transport, and processing.

The efficient cutting capacity of the plastic Dana cutter can significantly increase productivity. By quickly and continuously cutting plastic strips, ensure the smooth and efficient operation of the entire granulation process.

Introduction of Plastic Pellet Cutting Machine

The plastic pellet cutting machine is an efficient and precise cutting machine, which is designed and manufactured with full consideration of the requirements of the plastic manufacturing process. It can stably cut plastic bar stock into pellets of the required length, ensuring the continuity and consistency of production. The cutting size can be adjusted according to the need to meet the needs of different customers.

Advantages Of Plastic Dana Cutter Machine

- High-efficiency cutting: the use of precision knives ensures fast cutting speed and uniform pellets.

- Flexibility: Suitable for a wide range of plastic materials to meet different production needs.

- Customizability: Cutting size is adjustable.

- Matching equipment: A vibrating screen can be installed after it to further control the quality of granules.

Application of Plastic Granule Cutter

Our plastic granule cutting machines can be applied to a wide variety of plastic materials, including but not limited to PP, PE, ABS, PVC, PET, PS, EPE, EPS, and more. No matter what type of plastic products you produce, our cutting machines are capable of handling them, providing you with efficient and accurate cutting services.

Plastic Granule Cutter Application Video

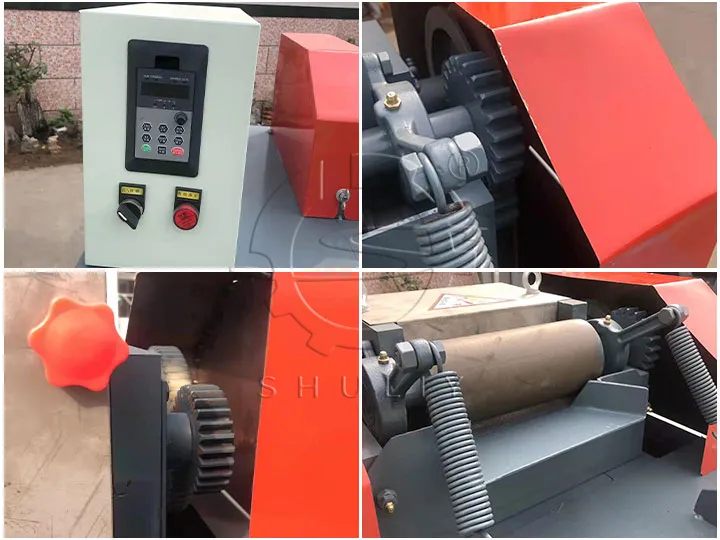

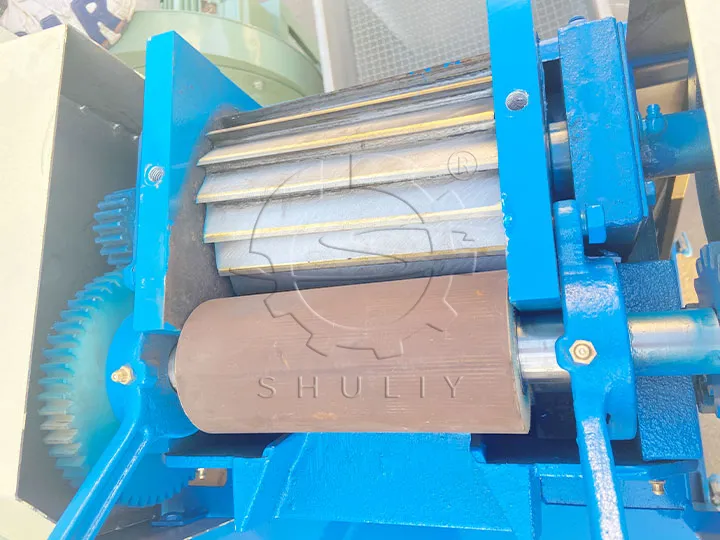

Structure Of Plastic Granule Cutting Machine

Our plastic granule cutter is mainly composed of a feed inlet, press wheel, rubber press wheel, hobbing knife, motor, body, and discharge outlet. Among them, the rotary knife is made of a hard alloy hob, with high service life and low maintenance cost.

How Does Plastic Pellet Cutting Machine Work?

First, the crushed and washed plastic enters the plastic scrap granulator to be heated and melted and then extruded into long plastic strips. The plastic strips then enter a cooling tank to be cured and cooled. Finally, it enters the plastic pellet cutting machine, where rotating blades or rollers precisely cut the pellets into uniform sizes as they pass through the cutting area.

Once the pellets are cut to the desired size, they are collected and prepared for further processing or packaging. The machine may include a mechanism for conveying the cut pellets to a storage container or packaging device.

What Is The Function Of A Vibrating Screen?

- Preventing Clumping: The temperature of the plastic pellets after cutting is around 60 degrees, making them prone to clumping. The vibrating screen disperses the pellets through vibration, reducing adhesion.

- Screening granules: Effectively filters out clumps of poor-quality pellets to ensure the quality and consistency of the final product.

- Improved efficiency: speeds up the process of particle separation and screening, increasing production efficiency.

Plastic Granule Cutter Specifications

- Model: SL-180, SL-220, SL-260

- Power: 3, 5.5, 5.5

- Type of knives: Hob

- Cutting size: About 3mm, can be customized

Our plastic Dana cutter is well designed with high efficiency and precise cutting ability. Made of high-quality steel with sharp and durable blades, the pellet cutting machine is capable of handling various types of plastics such as PE, PP, PVC, and PET. If you are interested in our Dana cutting machine or other plastic recycling solutions, please feel free to contact us. We will be happy to provide you with professional solutions and high-quality service.