EPS Pelletizing Machine

EPS pelletizing machine is a kind of equipment specialized in processing waste EPS foam material into pellets. This article introduces the functions, features, structure and specifications of the machine.

EPS pelletizing machine is a professional recycling equipment used to process EPS (polystyrene) raw materials and convert them into granular materials. In this article, we will introduce the application, characteristics, structure, and superior parameters of EPS granulators.

The video below shows how the EPS granules making machine processes waste EPS foam into granules. If you are interested in the machine or other foam recycling equipment, please feel free to contact us, we will provide professional solutions and high-quality service for you.

Features of The Foam Granulator

- High efficiency and energy saving: Adopting advanced heating and extrusion technology, it can efficiently convert EPS raw materials into pellets, and at the same time, it is characterized by energy saving.

- Precise control: The equipment is equipped with a precise temperature control system and extrusion speed control system, which can ensure the stable quality of pellets.

- Customizability: Our EPS pelletizing machine is available in a variety of models and can also be customized to meet specific customer requirements.

Functions of EPS Granulator

The main function of the EPS Pelletizing machine consists of heating and melting the EPS raw material and then extruding it into strips through an extrusion system and then cutting it into pellets through a plastic granule cutter. These granular materials can be used in a variety of filling, packaging, and insulation applications.

EPS Granulator Raw Materials

EPS foam granule machines are mainly used to process EPS foam materials, and the specific materials that can be processed include but are not limited to:

- Foam fast food containers, fresh food containers

- Insulation materials

- Packaging foam for TVs, air conditioners, and other home appliances

- Electronics packaging foam

- Medical device packaging foam

- Building insulation materials, etc.

EPS Pelletizing Machine Structure

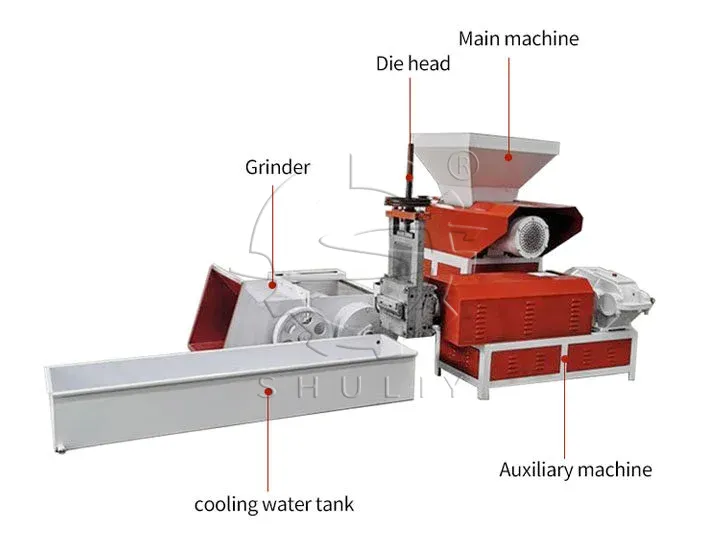

EPS foam granules machine consists of a main machine, auxiliary machine, feed inlet, motor, die head, crushing device, barrel, screw, control cabinet, heating device, and so on. The following figure is a simple structure diagram.

EPS Granulation Workflow

In the EPS granulation process, expanded polystyrene (EPS) waste is first put into the styrofoam shredder for crushing. The crushed material is conveyed through pipes and fans at the outlet to a hopper connected to the pelletizer. Next, the material enters the foam granulator where it is heated and melted before being extruded through a die to form a continuous strip. The plastic strip is cooled and then enters the pellet cutter, where it is cut into small, uniform pellets, thus completing the entire pelletizing process.

Foam Granulator Working Video

EPS Pelletizing Machine Specifications

| Model | 220 | 270 | 320 | 350 |

| Capacity (KG/H) | 150-175 | 200-225 | 275-300 | 325-375 |

| Main motor (KW) | 15 | 18.5 | 18.5 | 22 |

EPS Granules Making Machine Exported to Suriname

We exported two foam granulators to our customer in Suriname for processing EPS foam and EPE foam respectively. The output of each machine is 150-200kg/h, which can efficiently convert waste foam into reusable granules and help the customer to improve recycling efficiency.

More machine details: Suriname Customer Orders Foam Granulator For EPE And EPS Recycling